Moving-iron cableless six-freedom-of-degree magnetic levitation moving platform

A motion platform, degree of freedom technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as cable interference movement, light source influence, etc., achieve high-precision measurement, improve control bandwidth, and improve anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

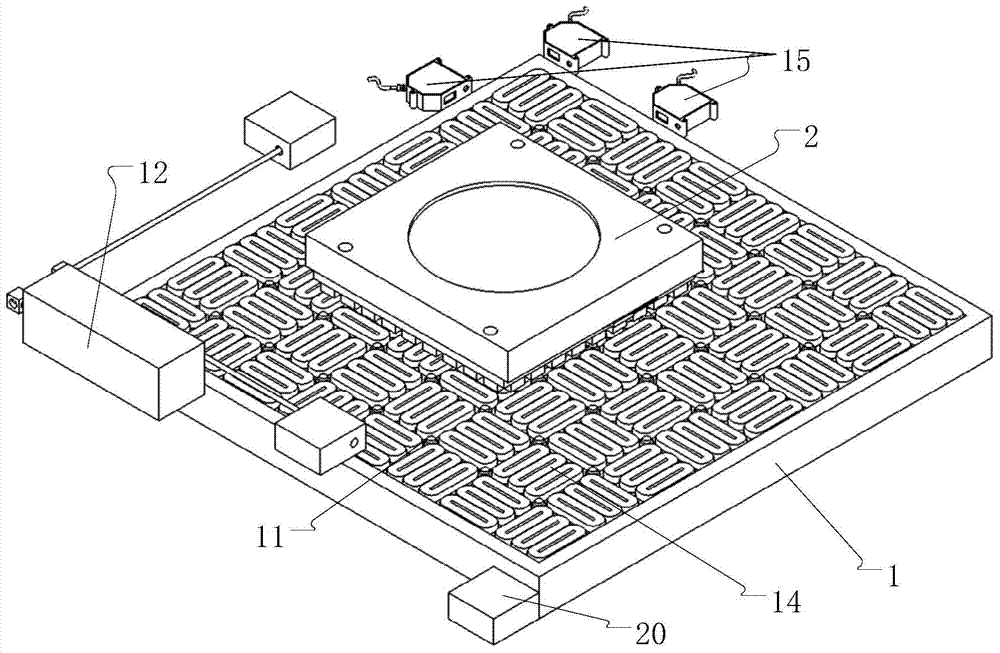

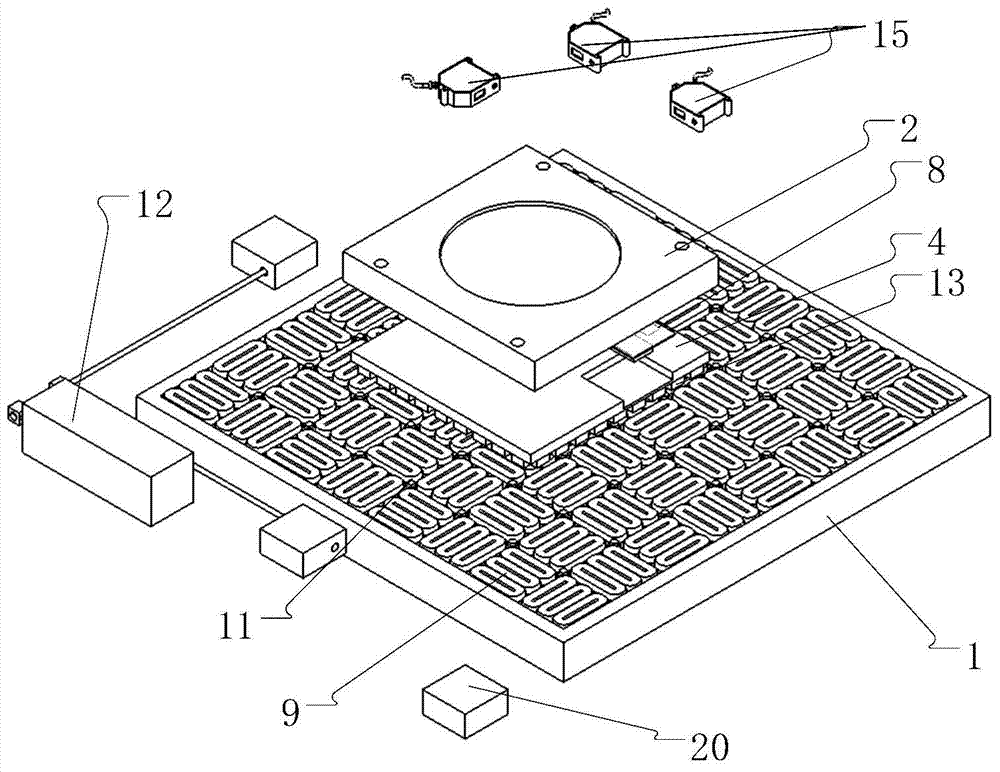

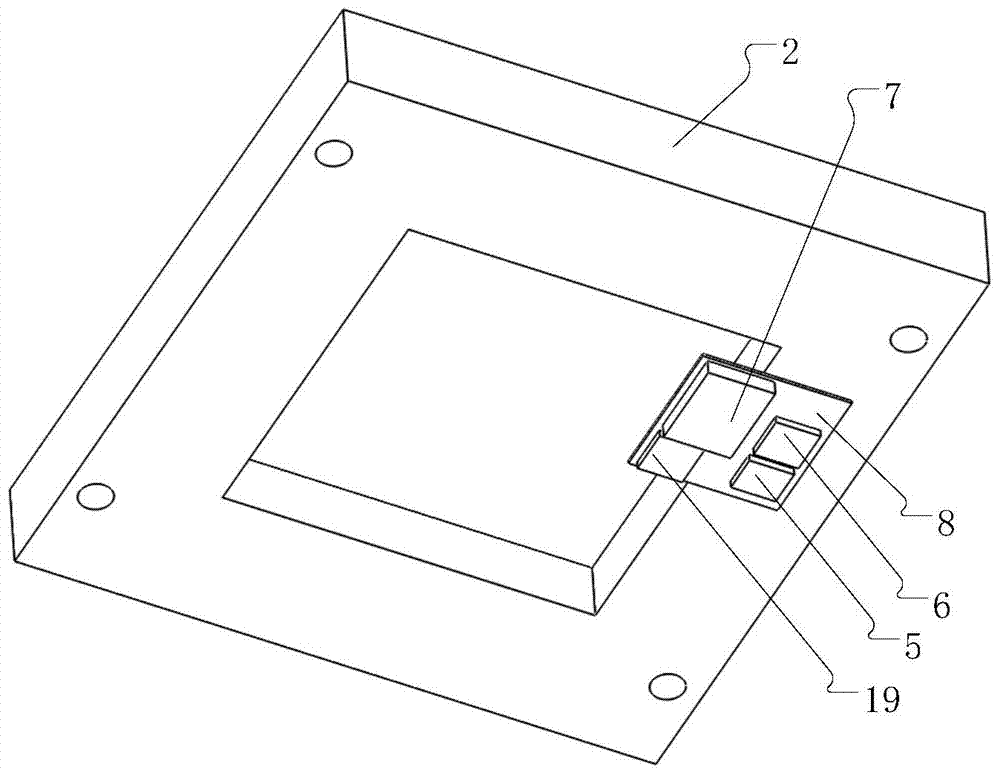

[0022] figure 1 , figure 2 A three-dimensional structure diagram of a moving-iron type cable-free six-degree-of-freedom maglev motion platform provided for the invention, the moving-iron type cable-free six-degree-of-freedom maglev motion platform includes a base 1, a stator, a mover, and a carrier Platform 2 and measuring system, described mover is made up of halbach permanent magnet array 13 and magnetic steel back plate 4; Described stator is the coil array 14 that is arranged by multiple groups of coil units 9; Described measuring system Including a laser interferometer measurement system 12, an eddy current sensor 11 and a laser triangulation sensor 15; a three-axis gyroscope 5 and a three-axis accelerometer are also arranged in the groove between the mover and the slide table 2 6. Power supply module 7 and wireless signal output module 19; a wireless signal receiving module 20 is set on the stator, the three-axis gyroscope 5, three-axis accelerometer 6 and power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com