A multi-stage expanded crushing chamber

A crushing cavity and expansion technology, applied in grain processing and other directions, can solve problems such as restricting crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

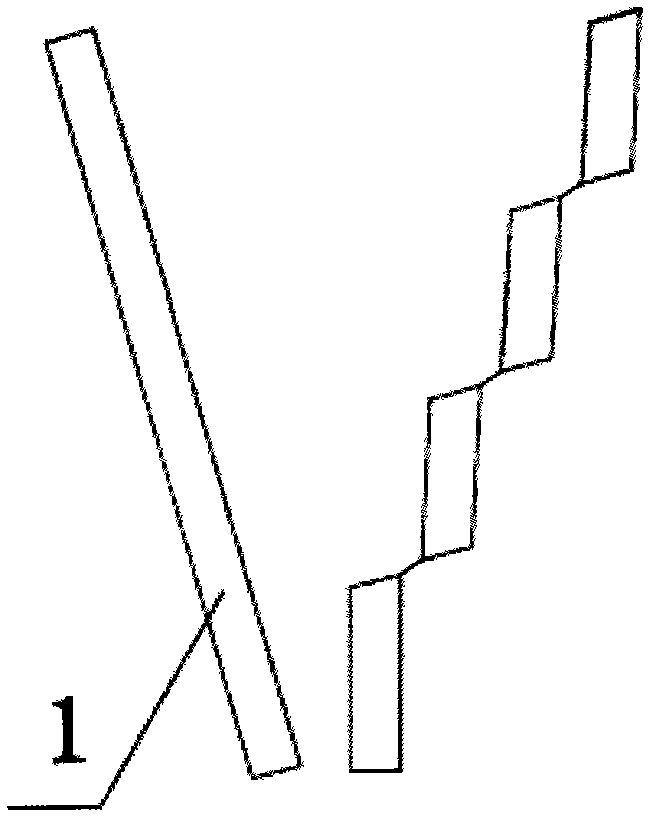

[0067] Embodiment 1: as figure 1 As shown, a multi-stage extended crushing cavity is composed of two opposing crushing surfaces, one of which is composed of four jaw plates 1 combined up and down; the four jaw plates 1 forming the crushing surface are separated and spliced to form a ladder Leap structure, the gap between the four jaw plates 1 connected between the two jaw plates 1 is filled by the movable jaw. The tooth structure on the four jaw plates 1 that make up the crushing surface also gradually decreases from top to bottom, that is, the tooth height gradually decreases, the tooth width gradually narrows, and the tooth spacing gradually decreases. .

[0068] The four jaw plates 1 that make up the crushing surface confront the corresponding jaw plates 1 that make up the crushing surface on the opposite side to form a stepped crushing cavity, and the size of the stepped crushing cavity expands step by step from bottom to top.

[0069] In the stepped crushing chamber, ...

Embodiment 2

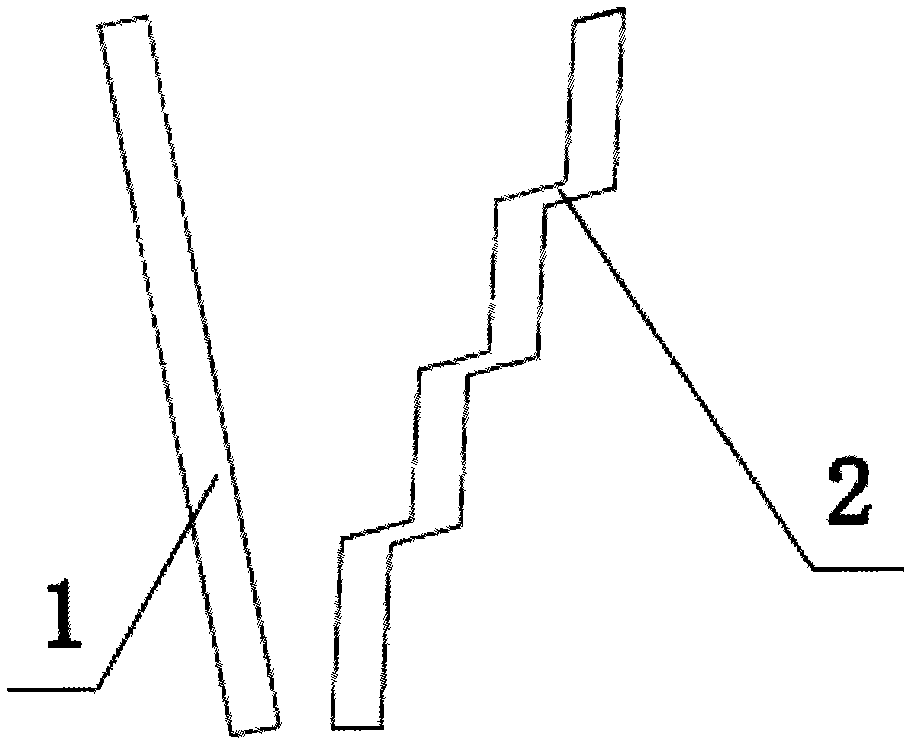

[0071] Embodiment 2: as figure 2 As shown, the four jaw plates 1 that make up the crushing surface are separated and integrally connected by connecting plates 2 to form a stepped structure.

[0072] The four jaw plates 1 that make up the crushing surface confront the corresponding jaw plates 1 that make up the crushing surface on the opposite side to form a stepped crushing cavity, and the size of the stepped crushing cavity expands step by step from bottom to top.

[0073] In the stepped crushing chamber, the last crushing chamber located at the lower end has a long and narrow structure. The length of the working surfaces of the two jaws forming the long and narrow structure is 550mm, and the angle range between the two working surfaces of the two jaws forming the long and narrow structure is -8 degrees. .

[0074] All the other are with embodiment 1.

Embodiment 3

[0075] Embodiment 3: The working faces of the two jaws 1 forming the long and narrow structure are all flat light plate structures.

[0076] The four jaw plates 1 that make up the crushing surface confront the corresponding jaw plates 1 that make up the crushing surface on the opposite side to form a stepped crushing cavity, and the size of the stepped crushing cavity expands step by step from bottom to top.

[0077] In the stepped crushing cavity, the final crushing cavity at the lower end has a long and narrow structure. The length of the working surfaces of the two jaws forming the long and narrow structure is 300mm, and the angle range between the two working surfaces of the two jaws forming the long and narrow structure is +1 degree. .

[0078] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com