A combined processing method for heavy oil with concurrent methane production

A technology for combined processing and methane production, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve problems such as high reaction temperature, regeneration and recovery of gasification catalysts, and complicated preparation of gasification feedstock, so as to avoid Effects of tail combustion, easy recovery of sulfur, and reduction of carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

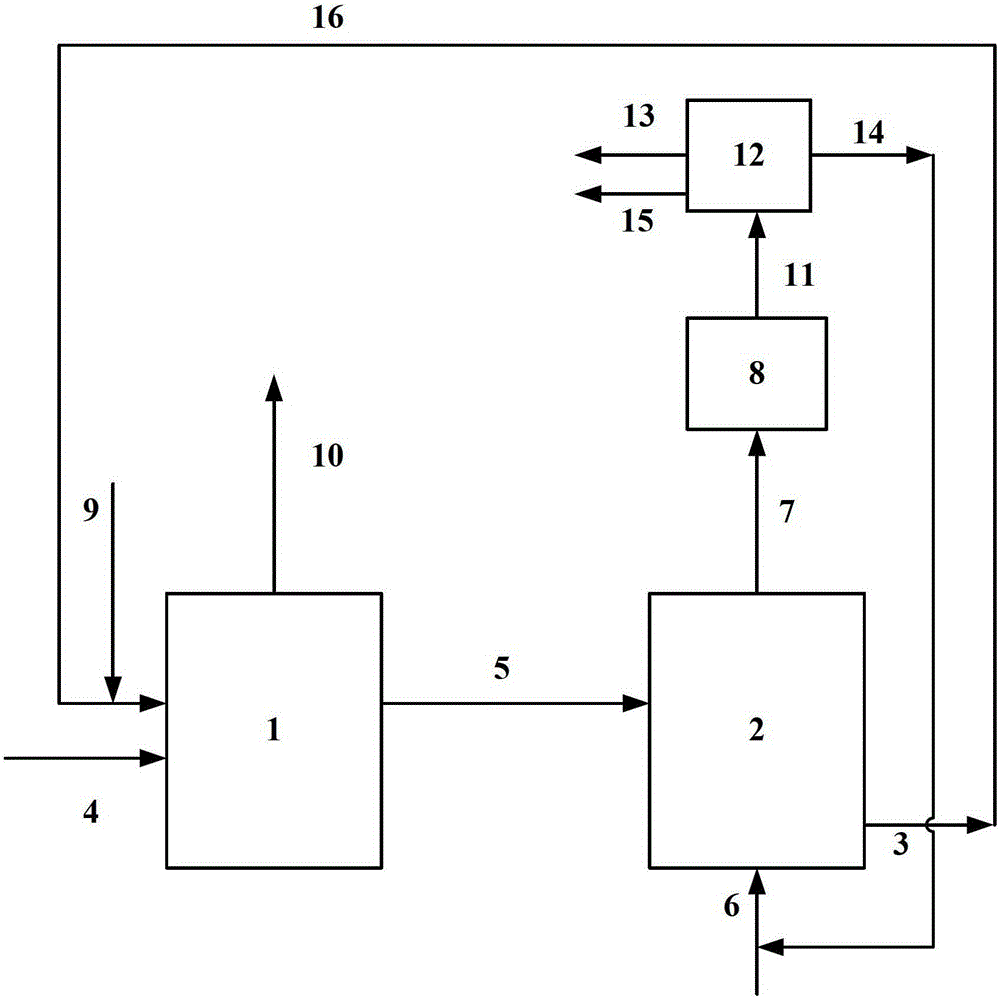

Method used

Image

Examples

Embodiment 1

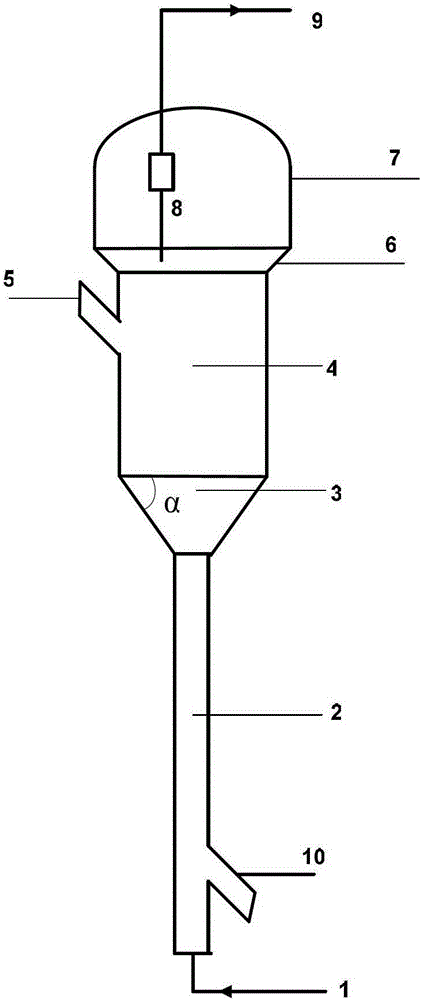

[0050] The catalytic cracking catalyst with the trade name of CRC-1 was mechanically mixed with the gasification catalyst GC-3 at a mass ratio of 1:1, with a residual carbon value of 15.10% by weight, a metal content of 50 μg / g, and a sulfur content of 1.12% (by mass) The contact cracking reaction of heavy oil occurs in the contact cracking unit, and the process conditions of the contact cracking reaction are: cracking temperature 460°C, space velocity 10h -1 , the agent-oil ratio is 10, the water-oil ratio is 0.1, and the coke content of the resulting spent agent is 1.8% by weight.

[0051] The raw agent enters the gasification unit after being stripped. The pressure of the gasification unit is 1.2Mpa. The raw agent enters the gasifier from the upper part of the reduction zone, and the gasification agent enters the oxidation zone of the gasifier from the bottom of the gasifier. In the oxidation zone, the temperature is 680°C, oxygen is 12.3% (mole), water is 87.7% (mole), the...

Embodiment 2

[0053] The catalytic cracking catalyst whose trade name is CRC-1 is mechanically mixed with the gasification catalyst GC-1, the mass ratio of the two is 3:7, and then the carbon residue value is 18.10% by weight, the metal is 200 μg / g, and the sulfur content is 1.12% (mass) heavy oil undergoes a contact cracking reaction in the contact cracking unit, and the process conditions of the contact cracking reaction are: cracking temperature 500°C, space velocity 20h -1 , the agent-oil ratio is 7, the water-oil ratio is 0.2, and the coke content of the resulting spent agent is 2.5% by weight.

[0054] The raw agent enters the gasification unit after stripping, the pressure of the gasification unit is 5.0Mpa, the raw agent enters the gasifier from the upper part of the reduction zone, and the gasification agent enters the oxidation zone of the gasifier from the bottom of the gasifier. In the oxidation zone, the temperature is 635°C, oxygen is 18.0% (mole), water is 82.0% (mole), the g...

Embodiment 3

[0056] The silicon-aluminum material MFC-1 and heavy oil with a residual carbon value of 35.0% by weight, a metal content of 425 μg / g, and a sulfur content of 3.12% (mass) undergo a contact cracking reaction in a contact cracking unit. The process conditions for the contact cracking reaction are: cracking temperature 520℃, space velocity 50h -1 , the agent-to-oil ratio is 20, the water-to-oil ratio is 0.5, and the coke content of the resulting spent agent is 2.8% by weight.

[0057] The raw agent enters the gasification unit after stripping. The pressure of the gasification unit is 8.1Mpa. The raw agent enters the gasifier from the upper part of the reduction zone, and the gasification agent enters the oxidation zone of the gasifier from the bottom of the gasifier. In the oxidation zone, the temperature is 700°C, oxygen is 10.0% (mole), water is 90.0% (mole), the gas linear velocity is 1.8m / s, and the gas residence time is 0.8 seconds. combustion. In the reduction zone, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com