Crushing hammer of hydraulic machine

A technology of breaking hammer and hydraulic press, which is applied in the field of hydraulic presses, can solve the problems of high cost, power consumption, and low crushing force, and achieve the effect of high work efficiency, strong force, and fast crushing of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Examples:

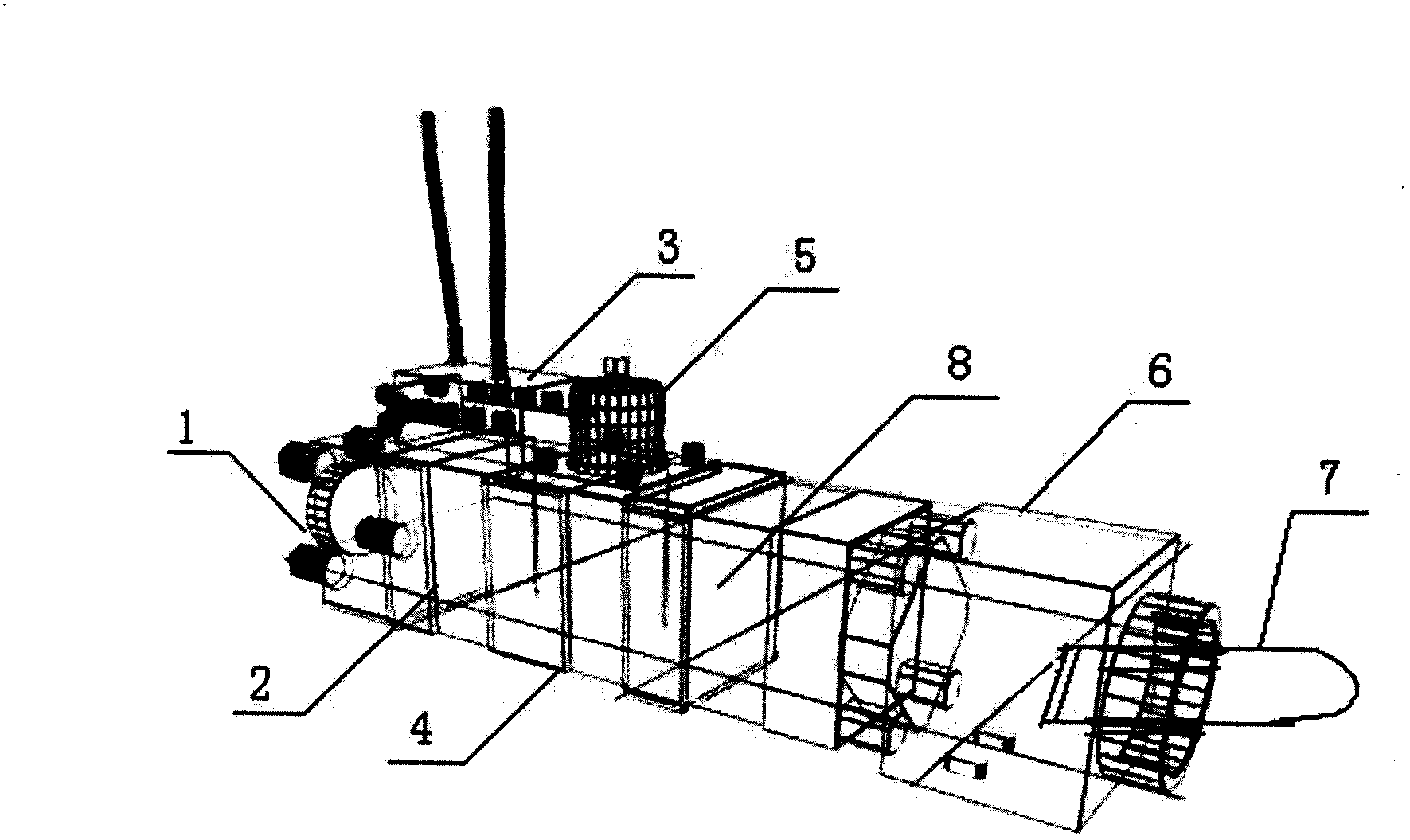

[0014] See figure 1 , Hydraulic breaker, including a middle cylinder block 4 and a front cylinder block 6 which are connected in one body. It also includes a rear nitrogen chamber 1 arranged at the end of the middle cylinder block 4 and a reversing valve arranged above the middle cylinder block 4. The assembly 3 and the piston 8 located in the inner cavity of the middle cylinder 4 and the front cylinder 6, and the front end of the piston 8 is connected to the hammer 7.

[0015] The piston 8 and the inner wall of the cylinder are provided with a piston ring 2 to support the piston 8, reduce friction, reduce air leakage, improve thermal efficiency, and make the connection between the piston 8 and the cylinder wall closer.

[0016] Above the middle cylinder 4, there is a high-pressure nitrogen chamber 5 on the side of the reversing valve assembly 3. The high-pressure nitrogen chamber 5 can supplement the air pressure to the piston 8 in the cylinder, so that the pisto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap