A method for quickly detecting the shape of lugs of joint parts and a measuring fixture

A technology for measuring fixtures and detecting joints, which is applied in the direction of mechanical counter/curvature measurement, etc. It can solve the problems of affecting processing efficiency, long production cycle, and difficult processing of titanium joint parts, so as to improve the qualified rate of measurement, and the detection results are reliable and fast. The effect of valid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

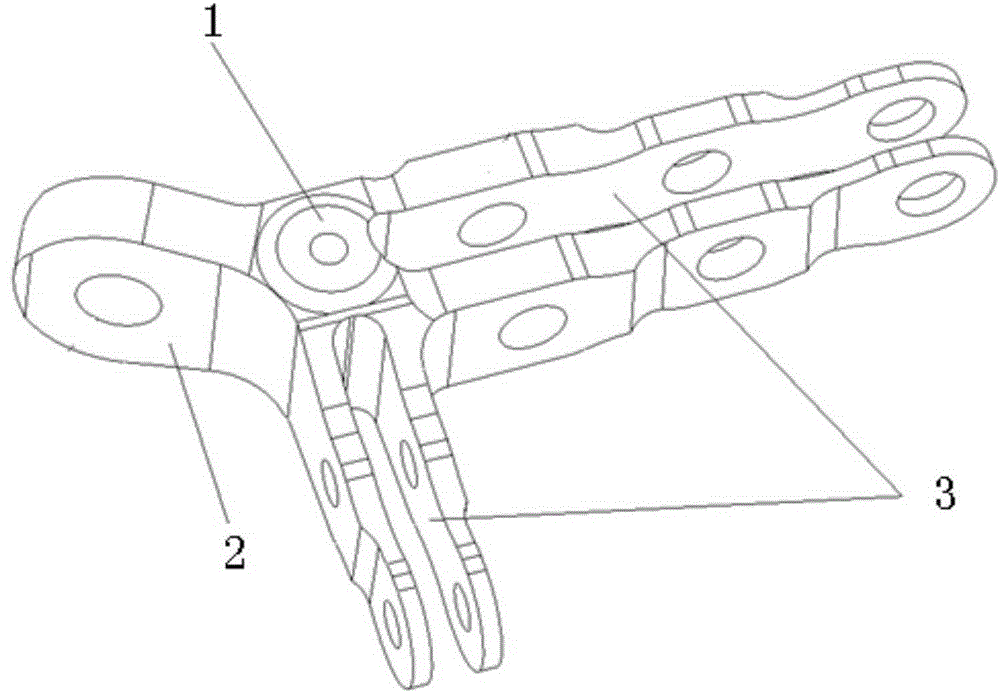

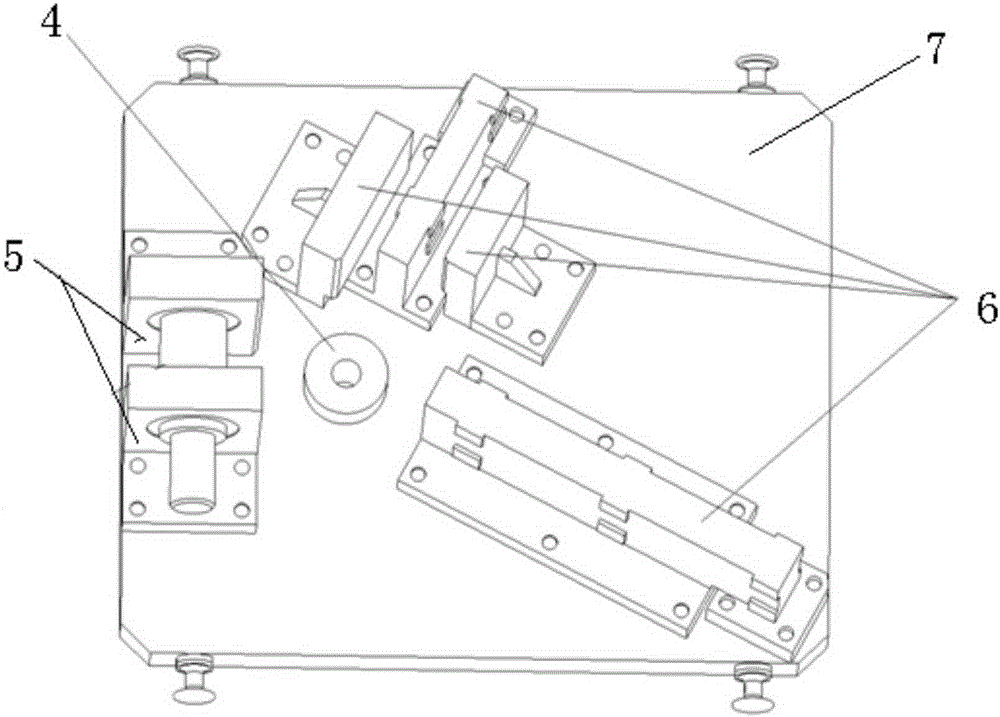

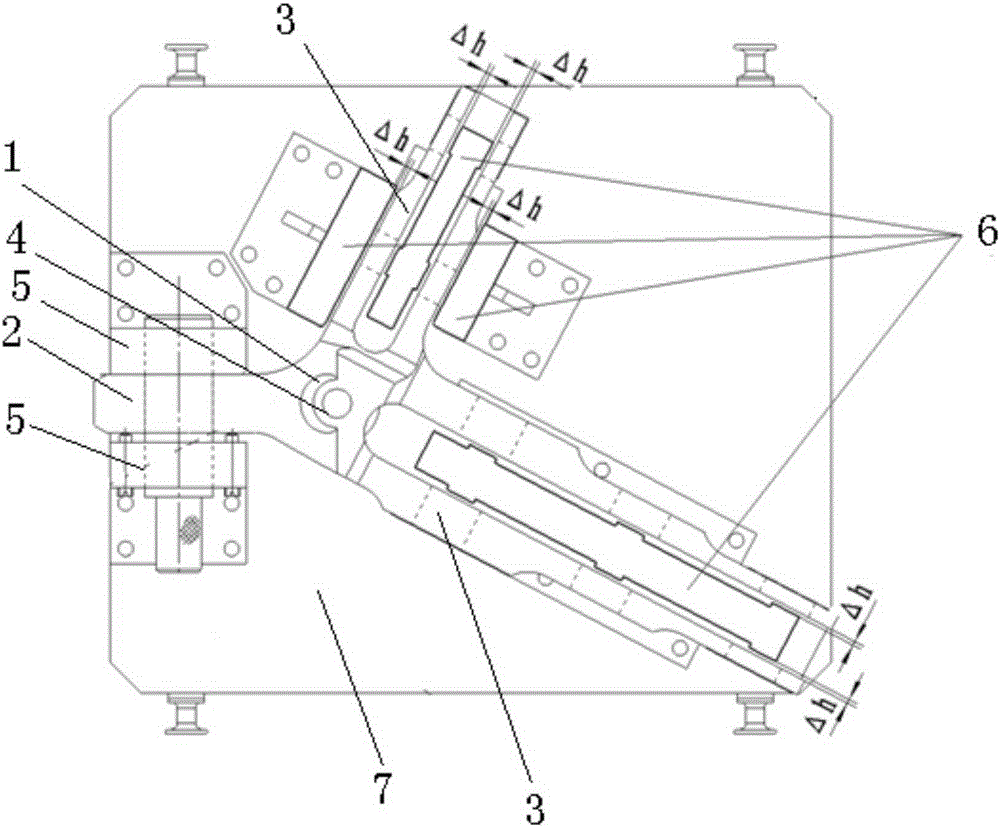

[0013] See attached picture, figure 1 It is a schematic diagram of a titanium joint part. The titanium joint part is Y-shaped. The center of the part is a positioning hole 1. There is a connecting through hole at the tail end 2 of the part. The two lugs 3 of the part are respectively in a fork-shaped structure. There are tab holes. The shape and location of the lugs and lug holes of this part have high requirements, and both need to be measured and tested. The lug holes are precision holes for assembly. The rapid detection method disclosed by the present invention is firstly to use the positioning hole 1 and the side wall of the tail end 2 of the part as a measurement reference; there is another measuring fixture, such as figure 2 As shown, the body 7 of the measuring fixture is a flat plate structure, and the body of the measuring fixture is provided with a positioning shaft 4 corresponding to the positioning hole 1 of the part, a clamping block 5 corresponding to the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com