Method for separating base oil family composition

A separation method and base oil technology, applied in material separation, base material, petroleum industry, etc., can solve the problems of large solvent consumption and complicated separation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

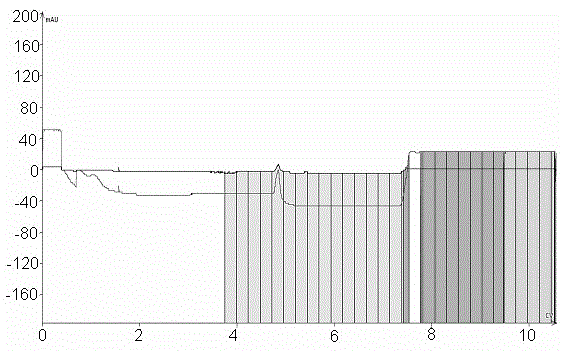

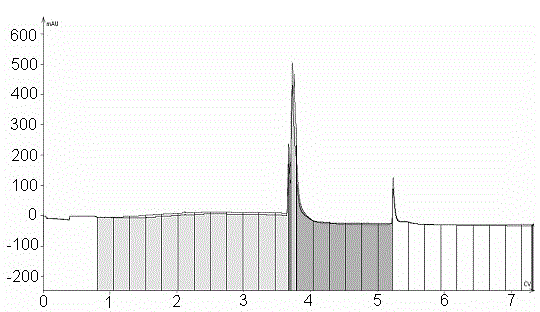

Image

Examples

Embodiment 1

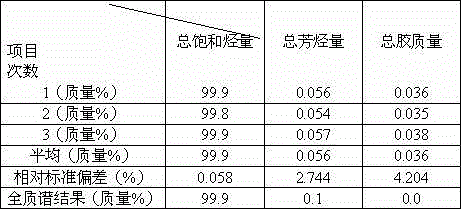

[0018] Accurately weigh 100.00 grams of lubricating oil base oil I, and then add 50.00 grams of petroleum ether to dilute for use. Weigh 750.00 grams of silica gel (200~300 mesh), add it to a chromatographic column (10 cm in diameter, 60 cm in length) with a solid addition funnel, and beat while adding it to make it compact. After the chromatographic column was thoroughly rinsed with petroleum ether, the diluted oil sample was directly sucked into the sample. Separation by liquid preparative chromatography was carried out in the order of non-polar solvent (n-hexane 1875 ml), medium polar solvent (chloroform 1500 ml) and polar solvent (isopropanol 1500 ml). The UV detector is automatically collected, and the products are collected according to the analysis results of the UV detector, and finally divided into three parts, namely the non-polar solvent eluate, the medium polar eluate and the strong polar eluate. The three eluates were evaporated under reduced pressure with a rota...

Embodiment 2

[0025] In the same way as in [Example 1], the group composition of lubricating base oil II was separated by liquid preparative chromatography. Only the non-polar solvent used is n-heptane, and the amount is 2000 ml; the medium polar solvent is chloroform, and the amount is 1500 ml; the polar solvent is n-propanol, and the amount is 1500 ml. The total saturated hydrocarbon content, total aromatic hydrocarbon content and total gum mass shown in Table 3 were obtained.

[0026] table 3

[0027] project Total Saturated Hydrocarbons Total Aromatics total glue quality Mass (g) 98.2 0.108 0.096 The proportion(%) 99.8 0.110 0.098

[0028] It can be seen from Table 3 that the total recovery rate is as high as 98.4% 。 In the same way, [Example 2] was repeated three times in parallel, and the average relative standard deviation was calculated to be 2.75%. Comparing the results with the full mass spectrometry results (which can only be accurate to 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com