Simulating perforating bullet, composite perforator and perforating operation method

A technology of composite perforation and perforating bullets, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., which can solve the problems such as the decline of formation effect, and achieve the effect of improving effect and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

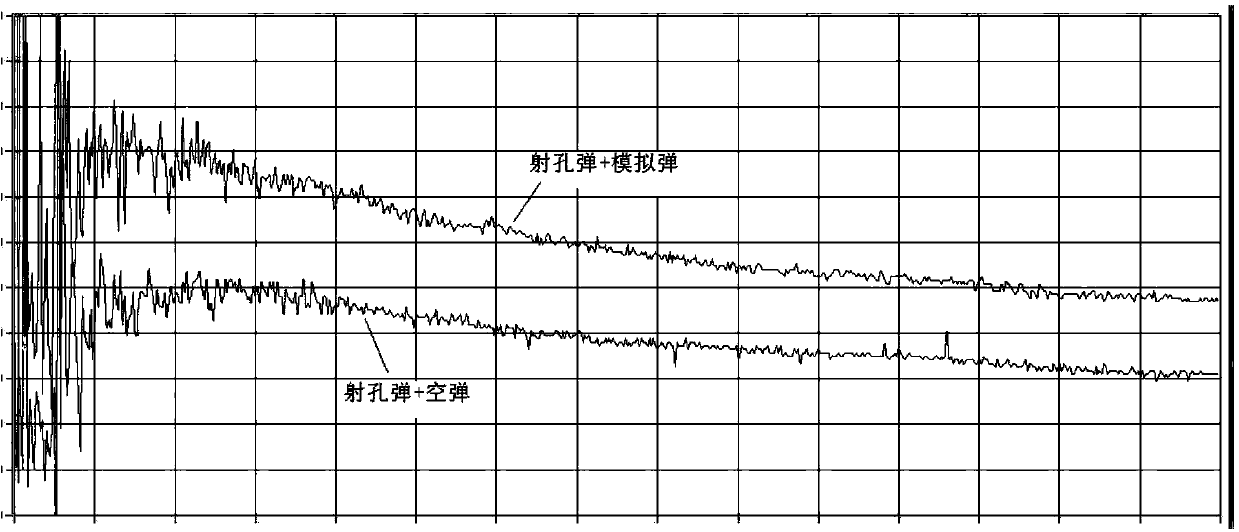

[0020] When the composite perforator performs perforating operations on formations with a small oil layer thickness, usually one part of the perforating bomb is installed in the loading hole of the bomb rack, and the other part is not loaded, and gunpowder is filled between each perforating bomb Therefore, the effect of some intervals is better and some intervals are inferior, which greatly reduces the effect of downhole composite perforation operations.

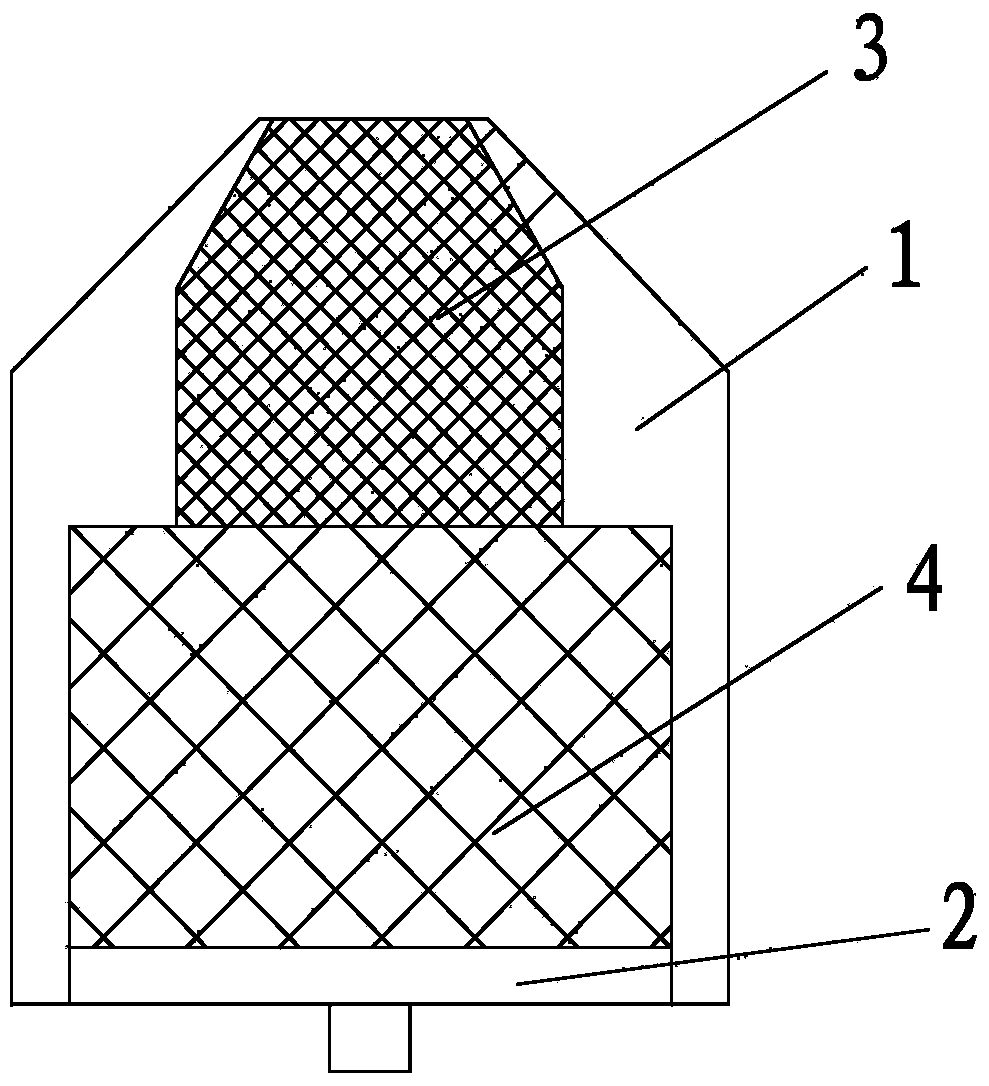

[0021] The simulated perforating bomb of the present invention includes a non-metallic material shell 1 and a non-metallic material end cover 2. The non-metallic material shell 2 is provided with two cavities, one is the explosive cavity 3 for containing explosives, The other is a gunpowder cavity 4 for holding gunpowder.

[0022] In particular, both the non-metallic material shell and the non-metallic material end cover can be made of plastic, rubber or ceramics.

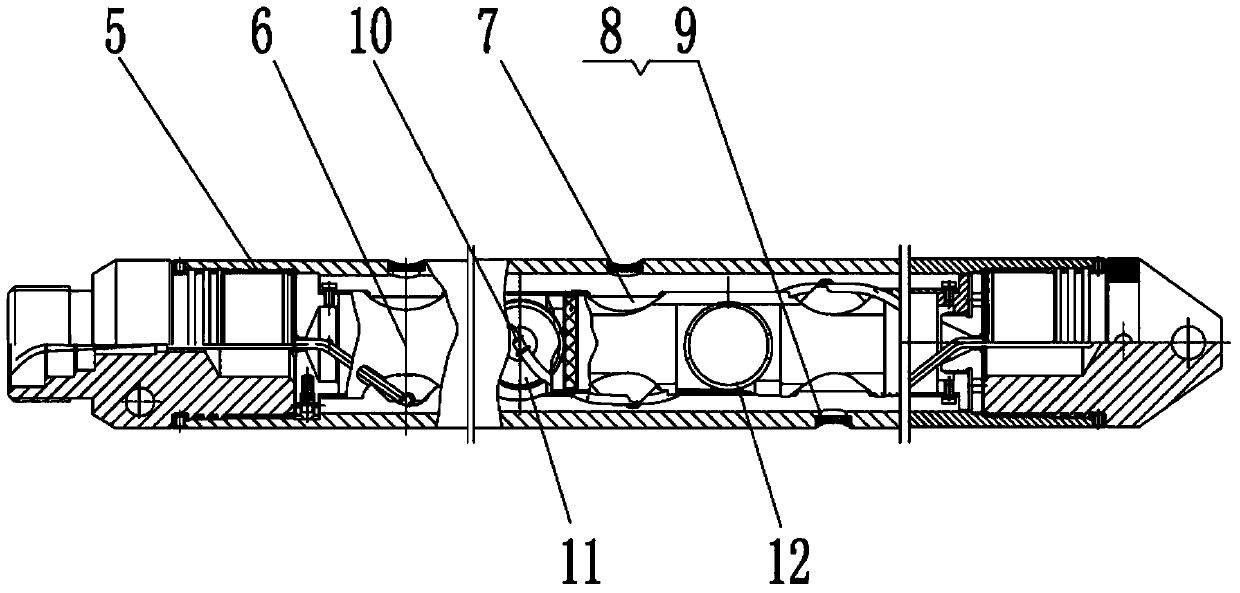

[0023] Based on the above-mentioned simulated perforating bullets...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap