Testing core rod and detection method for detecting mechanical property of connection sleeve

A technology for connecting sleeves and detection methods, which is applied in the field of test mandrels for detecting the mechanical properties of connecting sleeves, and achieves the effects of simple operation, improved test efficiency, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

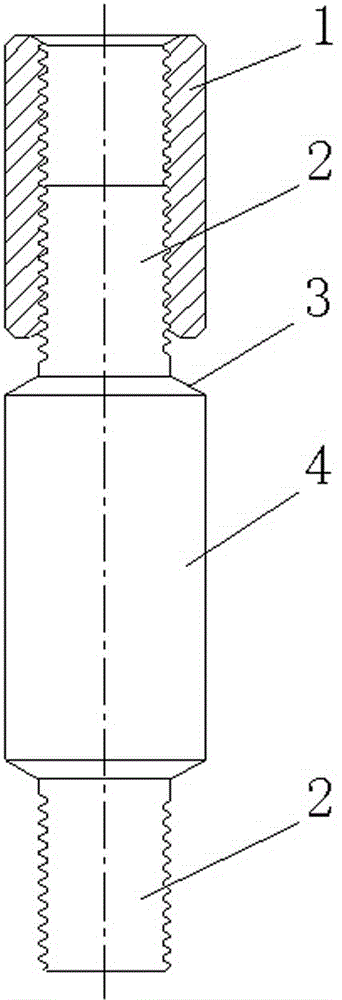

[0014] like figure 1 As shown, the present invention is used to detect the test mandrel of the mechanical performance of the connecting sleeve, the middle part of the mandrel is a cylindrical clamping section 4, and the two ends are respectively provided with connecting sections 2, and its diameter is smaller than the diameter of the cylindrical clamping section 4 . The tensile load of the mandrel is greater than or equal to 1.2 times the specified tensile load of the connecting sleeve 1 .

[0015] The connecting section 2 of the mandrel is provided with an external thread to match the internal thread of the sleeve 1 .

[0016] The diameter of the clamping section 4 of the mandre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap