A grounding ring structure of a wind power generator rotor

A grounding technology for wind turbines and rotors, applied in structural connections, connections with grounding devices, electrical components, etc., can solve problems such as corrosion, affecting product grounding reliability, inconvenience, etc., to facilitate maintenance, improve reliability and safety Sexuality, easy to use and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

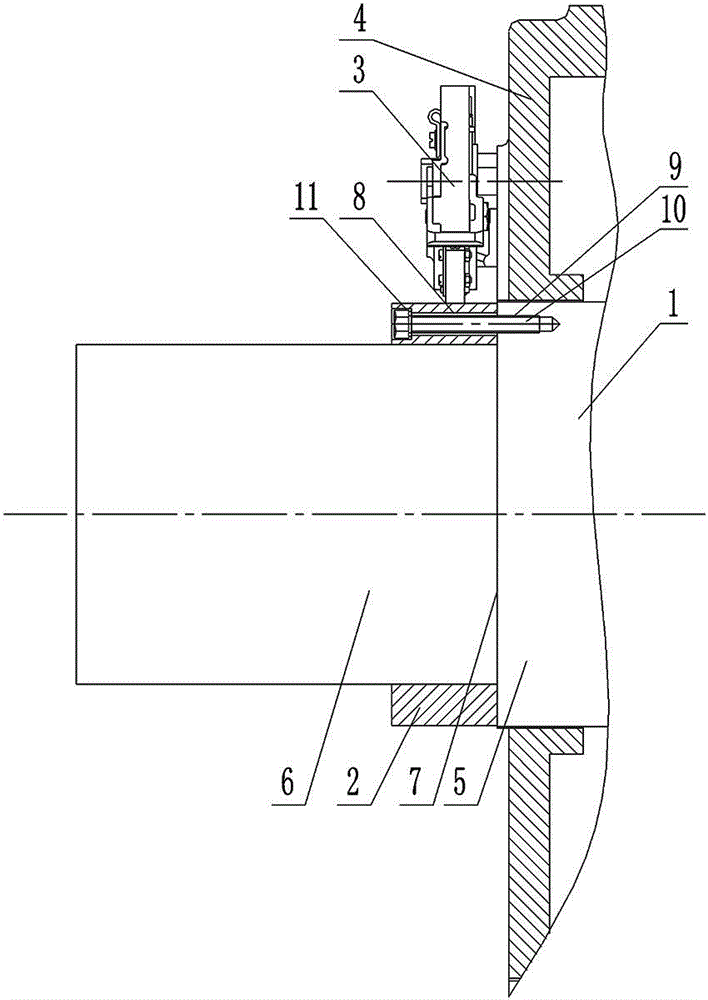

[0014] Such as figure 1 As shown, the wind turbine rotor grounding ring structure includes a main shaft 1, a cylindrical grounding ring 2 and a grounding carbon brush 3. The main shaft 1 includes a large-diameter section 5 located inside the bearing outer cover 4 and a large-diameter section 5 located inside the bearing cover. The outer small-diameter section 6, the connection between the large-diameter section 5 and the small-diameter section 6 forms a stepped end surface 7, the grounding ring 2 is set outside the small-diameter section 6 and pressed against the stepped end surface 7, and the side wall of the grounding ring 2 is evenly distributed along the circumferential direction There are at least two connecting through holes 8 extending in the axial direction. In this embodiment, six connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com