Mulberry leaf harvester with belt reciprocating type driving function

A reciprocating harvester technology, applied in the field of belt reciprocating drive mulberry leaf harvester, can solve the problems of unstable center of gravity, low production efficiency and high structure, and achieve the effects of improving efficiency, reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

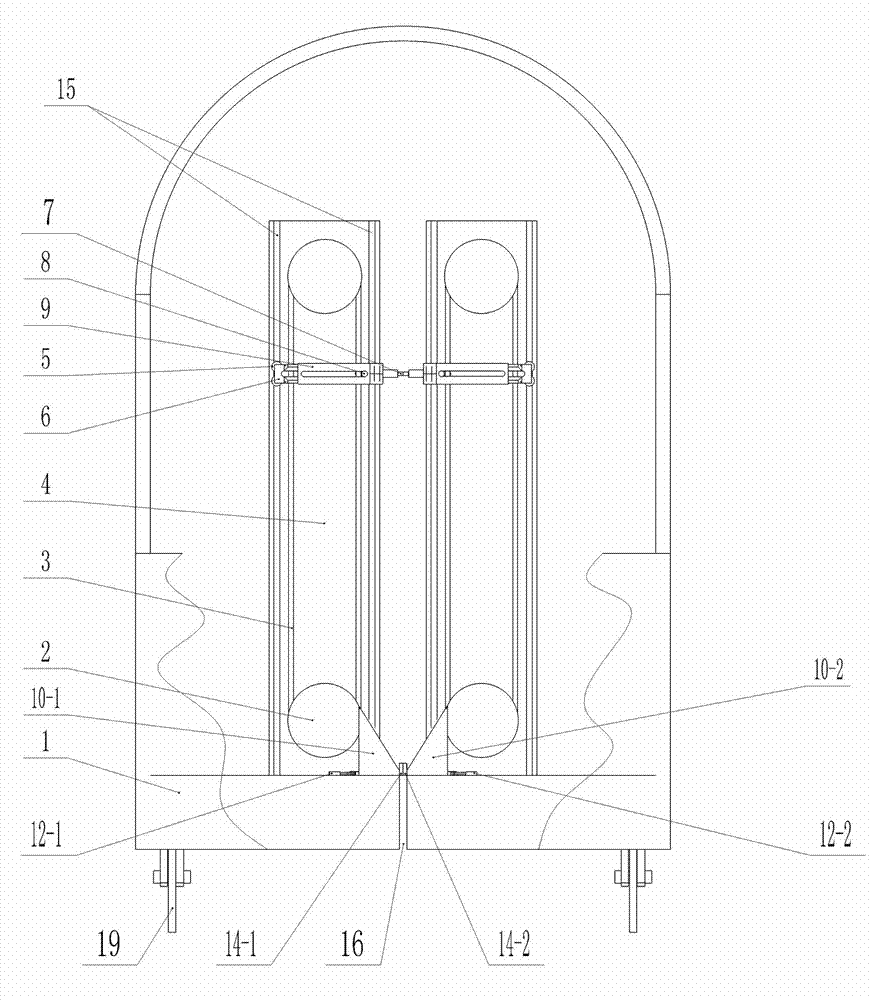

[0029] refer to Figure 1-Figure 6 , a belt reciprocating drive mulberry leaf harvester, comprising a walking device, a base device, a mulberry branch positioning device and a leaf cutting device, the base device is arranged on the walking device, the mulberry branch positioning device and the leaf cutting device are arranged on the base device, The positioning baffle plate of the described mulberry branch positioning device is vertically arranged on the cutter 7 front of the leaf cutting device, and the cutter lifting device of the leaf cutting device is vertically arranged on the base device, and two cutters 7 in the leaf cutting device are arranged on the mulberry branch above the positioning device.

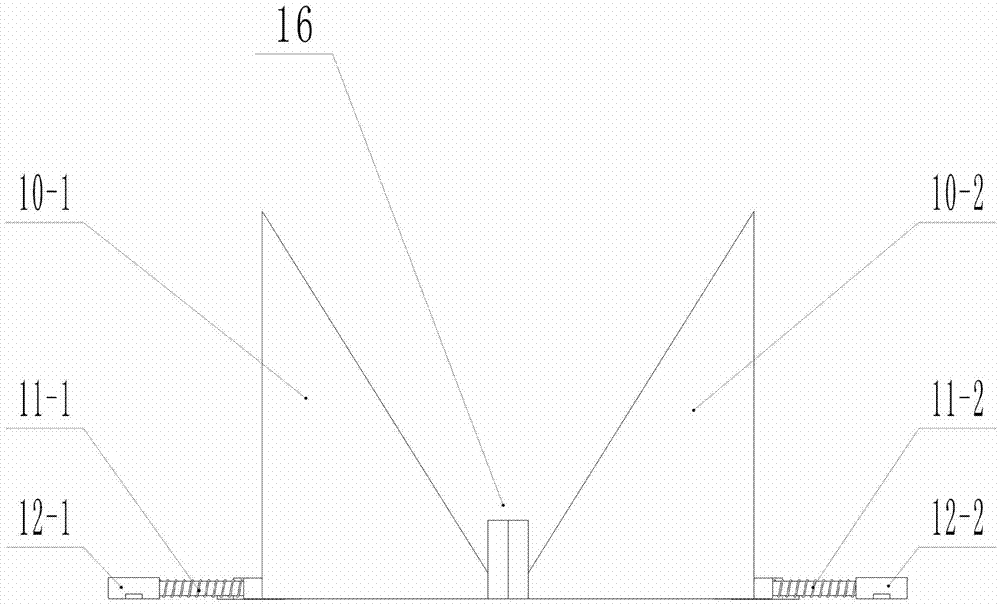

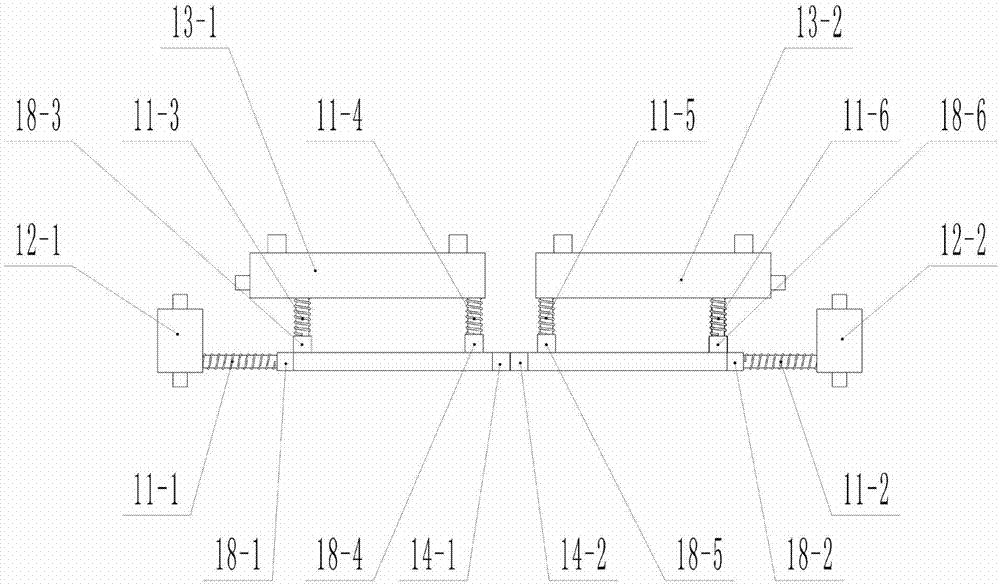

[0030] Such as figure 2 image 3As shown, the mulberry branch positioning device includes a positioning mechanism, and the positioning mechanism includes two positioning rods and two positioning baffles, namely the first positioning rod 14-1 and the second positioning rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com