Abrasive band grinding device used for complex curved surface

A technology for abrasive belt grinding and complex curved surfaces, which is applied in the direction of abrasive belt grinders, grinding machines, grinding slides, etc., can solve the problems of inability to rotate quickly, unsatisfactory, low efficiency, etc., and achieve the effect of improving fatigue strength and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

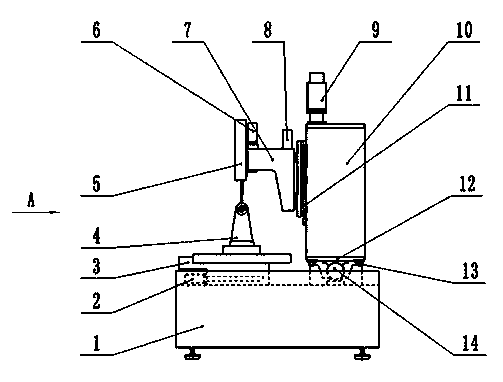

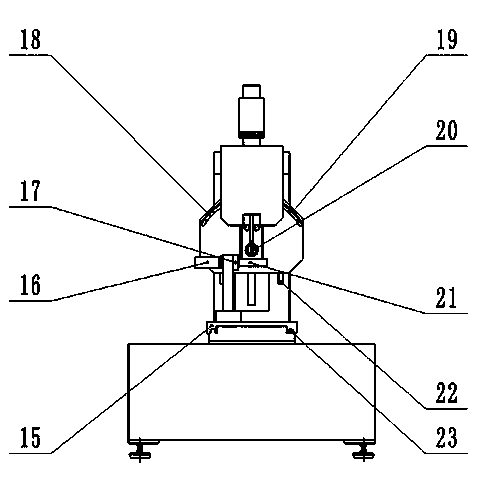

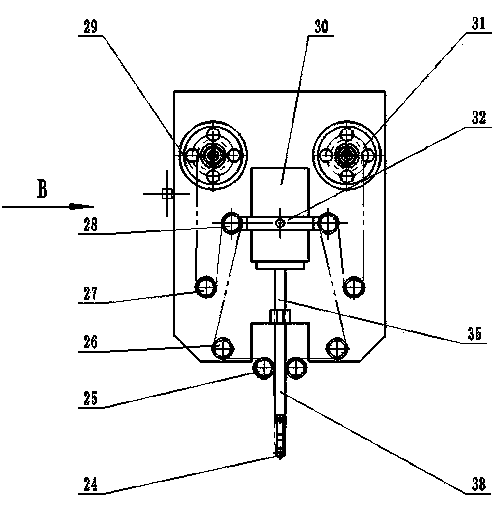

[0022] Such as figure 1 and figure 2 As shown, the abrasive belt grinding device for complex curved surfaces includes an X-axis bed 1 , a Y-axis bed 3 , a Z-axis bed 10 , a table assembly 4 , a grinding head seat 7 and a grinding head assembly 5 .

[0023] One end of the upper surface of the X-axis bed 1 is provided with two X-axis guide rails 13 parallel to the X-axis direction, and an X-axis sliding base 12 is slidably installed on the X-axis guide rails 13. The X-axis sliding base 12 and the X-axis guide rail 13 With single degree of freedom, the X-axis sliding base 12 can be driven by the X-axis motor 14 to drive the ball screw, and slide on the X-axis guide rail 13 . The bottom of the Z-axis bed 10 is installed on the X-axis sliding base 12 , and the Z-axis bed 10 can slide on the X-axis guide rail 13 .

[0024] The Y-axis bed 3 is arr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap