Automatic sponge sheet grabbing mechanism

A grabbing mechanism and sponge technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of uneven edges of finished products, high labor intensity of workers, and substandard product quality, and achieve quality assurance, compact structure, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

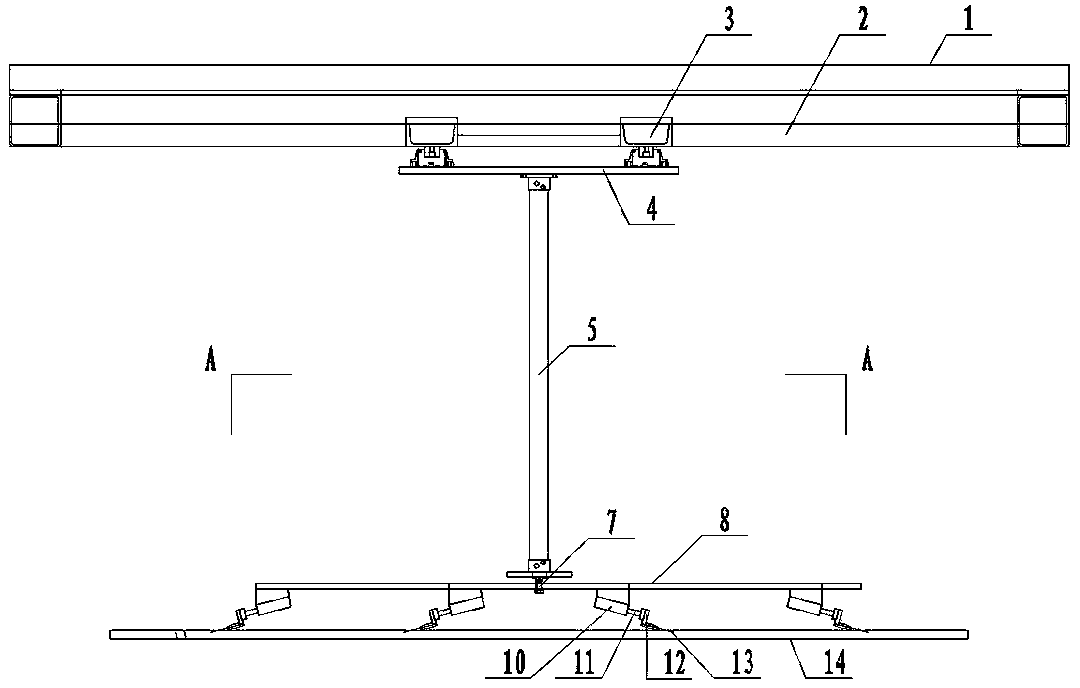

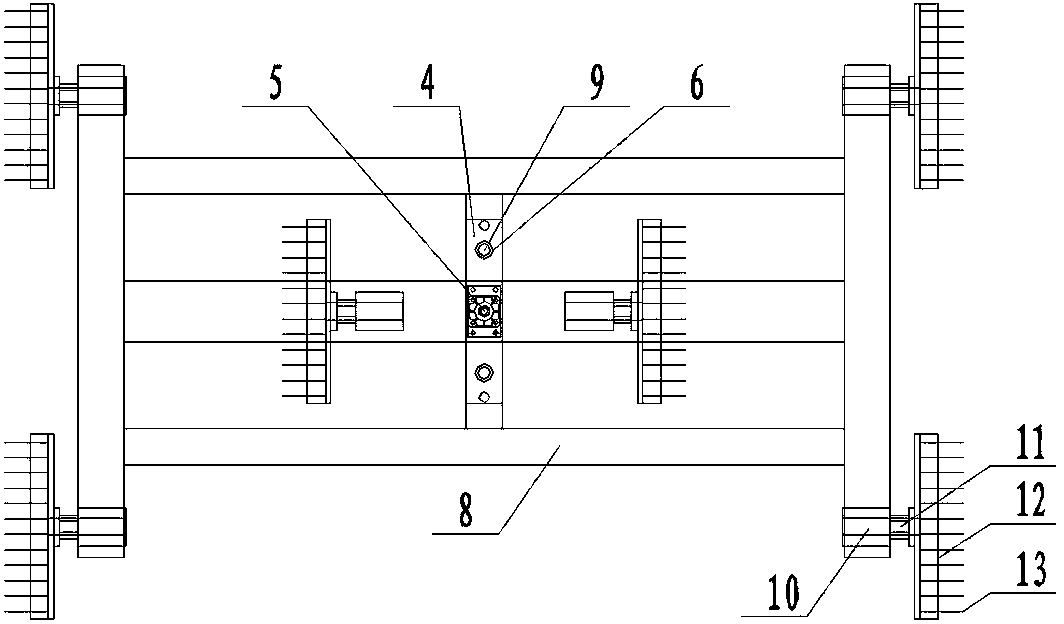

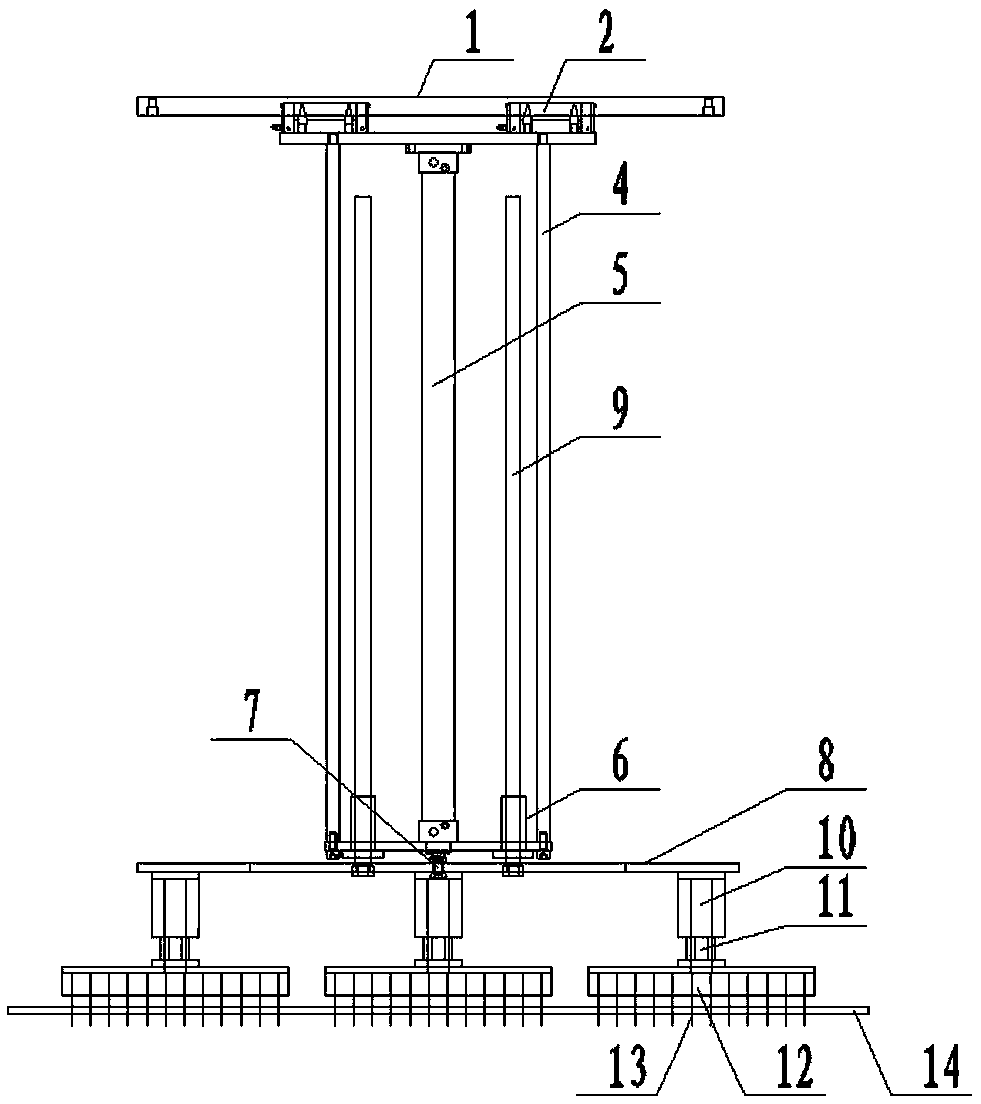

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the sheet sponge automatic grabbing mechanism includes: a frame 1, a guide rail 2 is arranged on the frame 1, and a sliding block 3 cooperating with it is slidably arranged on the guide rail 2. The lower end of the block 3 is connected with a sliding frame 4, on which a lifting cylinder 5 is arranged, and a guide sleeve 6 is arranged on the sliding frame 4 on both sides of the lifting cylinder 5, the piston rod 7 of the lifting cylinder 5 is connected to the Lifting bracket 8 is connected, on described lifting bracket 8, be provided with the guide rod 9 that cooperates with guide sleeve 6 mutually, be provided with some pin thin biaxial magnet cylinders 10 at the lower end of described lifting bracket 8, described pin The piston rod 11 of the thin do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com