low noise valve assembly

A technology of valve components and piston components, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., and can solve problems such as interference and high-frequency vibration of shock absorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Example embodiments will now be described more fully with reference to the accompanying drawings.

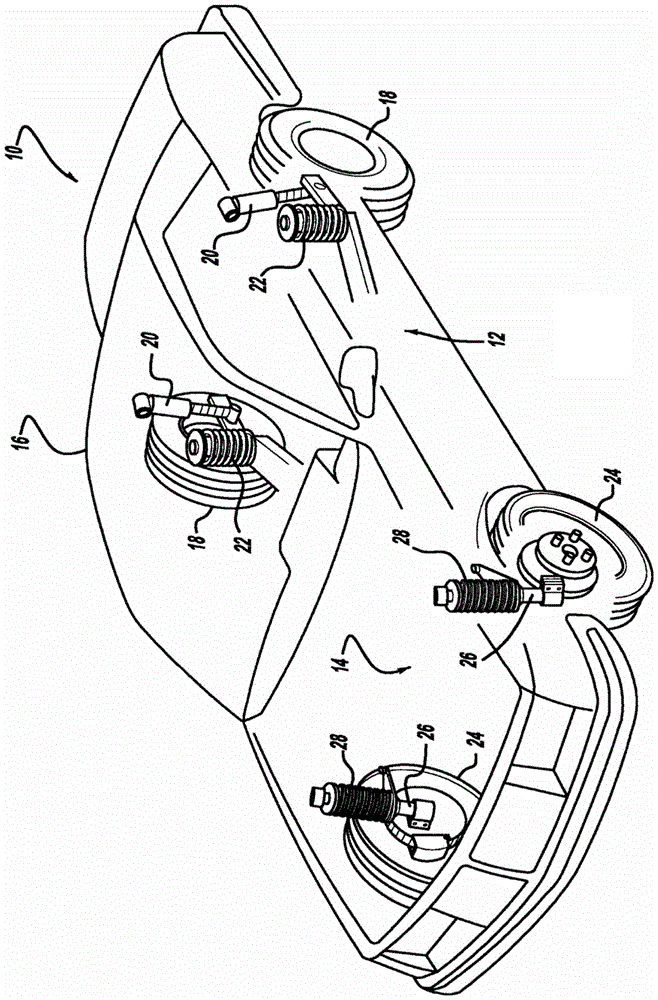

[0021] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses. figure 1 A vehicle comprising a suspension system having shock absorbers each comprising a piston assembly according to the invention is shown in , generally indicated by reference numeral 10 . The vehicle 10 includes a rear suspension 12 , a front suspension 14 and a body 16 . The rear suspension 12 has a laterally extending rear axle assembly (not shown) adapted to operatively support a pair of rear wheels 18 . The rear axle is attached to the body 16 by means of a pair of shock absorbers 20 and a pair of springs 22 . Similarly, the front suspension 14 includes a transversely extending front axle assembly (not shown) for operatively supporting a pair of front wheels 24 . The front axle assembly is attached to the body 16 by a pair of shock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com