Cell connector, battery cell module and manufacturing method thereof, battery and motor vehicle

A technology for battery cells and connectors, applied in the field of battery cell connectors, can solve problems such as troublesome cost, and achieve the effects of low-cost manufacturing, simplicity and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

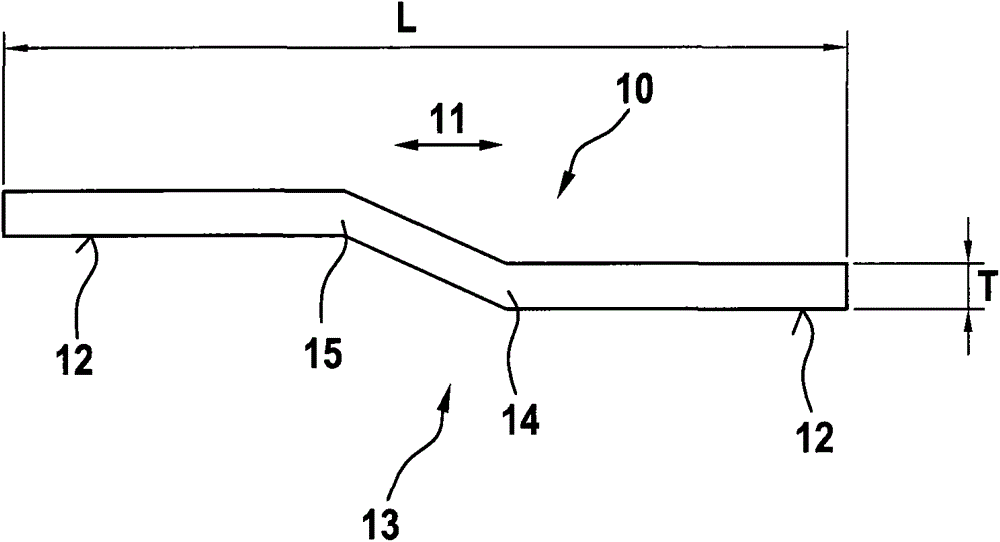

[0033] figure 1 A portion of a first battery cell 20 is shown, with terminals 21 provided on its surface. A cutout 24 is formed in the terminal 21 , in which cutout the cell connector 10 is positioned. The cell connector 10 is conductively connected to the terminal 21 by means of a fillet weld 25 .

[0034] The width W of the cell connector 10 is preferably dimensioned in such a way that the cell connector 10 can be accommodated in the recess 24 in the terminal 21 with a substantially precise fit.

[0035] In order to obtain a battery cell module composed of battery cells 20 , at least two battery cells 20 are electrically conductively connected via a cell connector 10 in the manner shown.

[0036] exist figure 2 shown in figure 1 A plan view of a detail of a battery cell 20 is shown. It is shown here that the cell connector 10 is severed at the cutting edge 26 , so that it still only forms a cell connector remainder 23 . The remainder 23 of the cell connector is electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com