Multi-measuring range CMOS MEMS capacitive pressure sensor chip

A pressure sensor and capacitive technology, applied in the field of design and manufacture of MEMS devices, can solve problems such as single range and incompatibility with CMOS technology, and achieve the effects of low manufacturing cost, improved manufacturability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

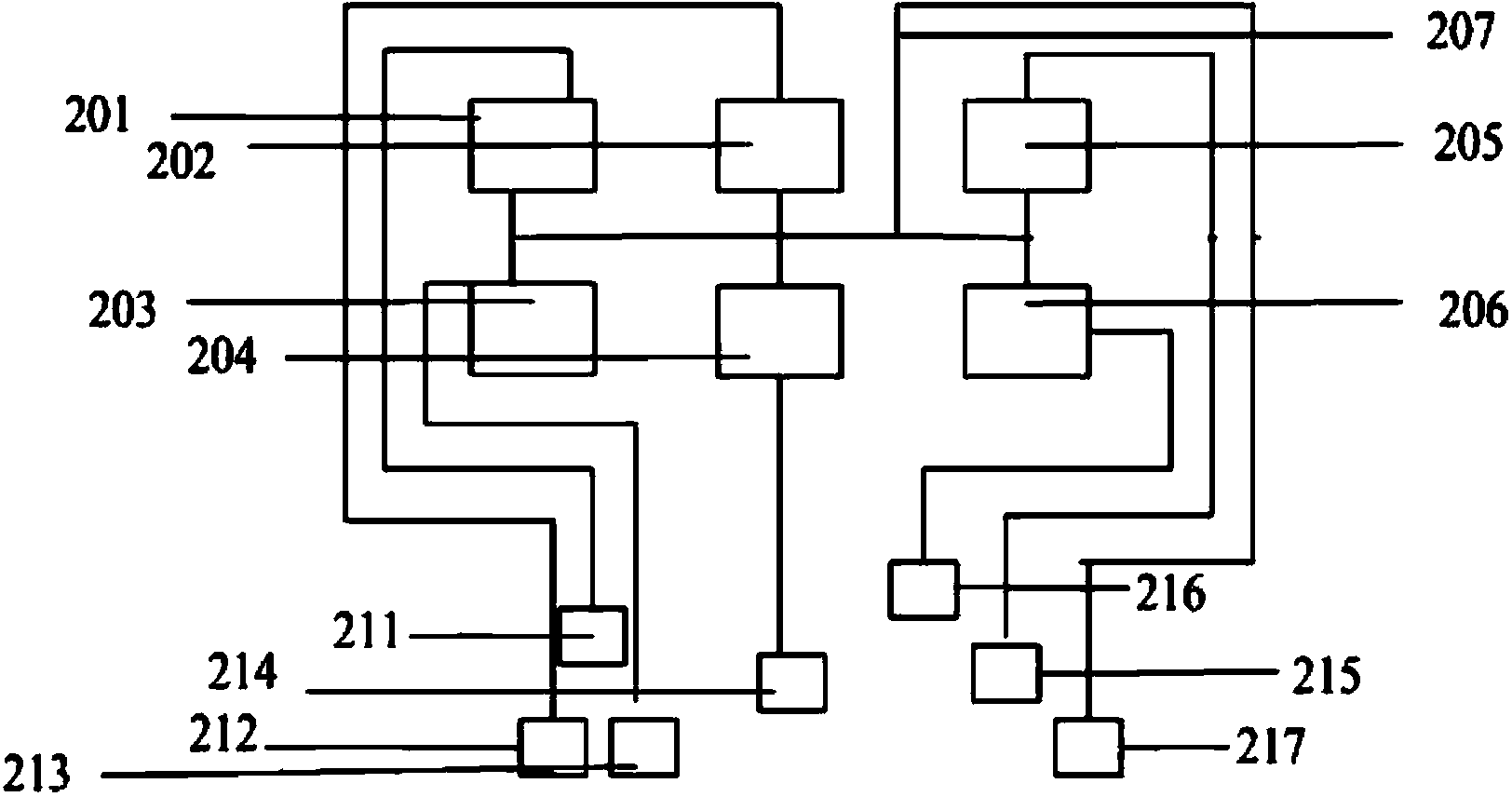

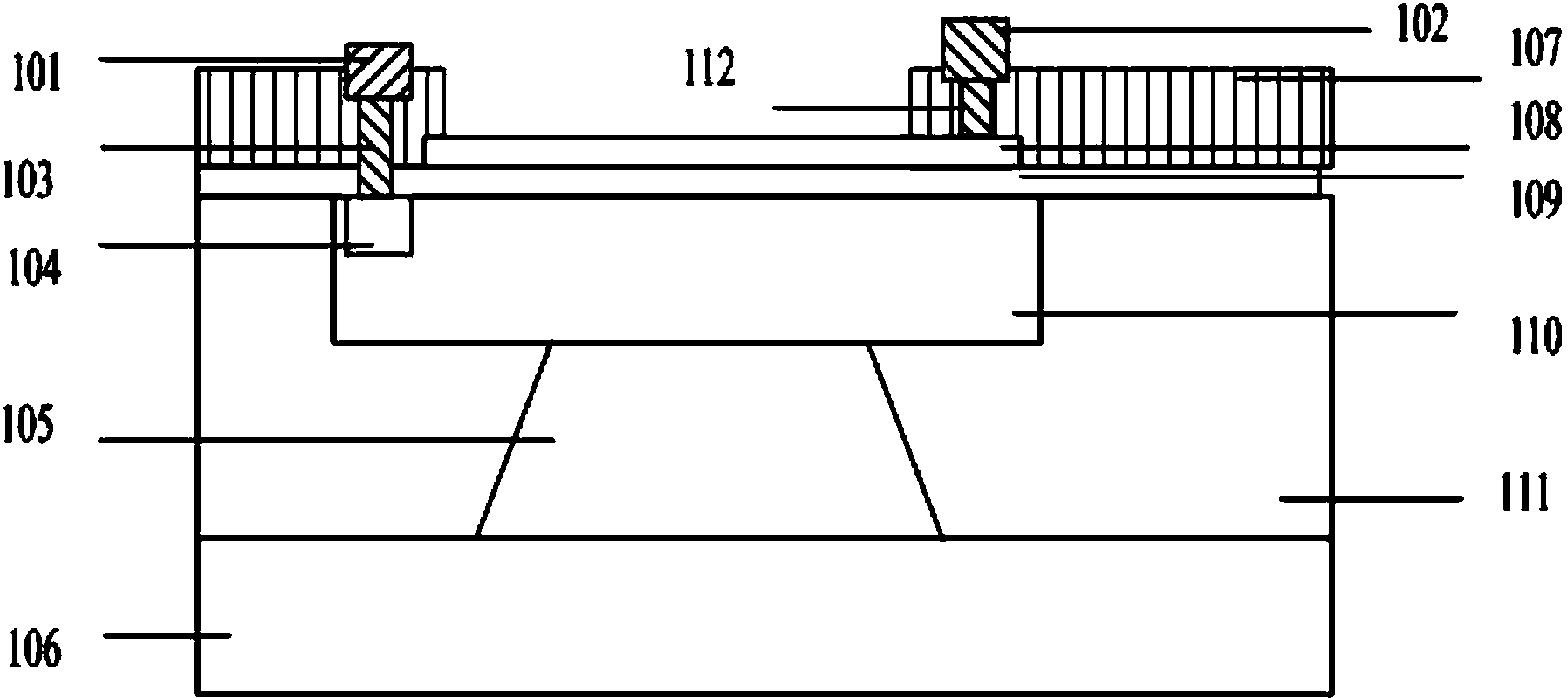

[0017] Such as figure 1 , figure 2 As shown: the multi-range CMOS MEMS capacitive pressure sensor chip includes a glass base 106 and a silicon substrate 111 arranged on the glass base 106, and the first pressure sensor unit 201, the second pressure sensor unit 201, and the The second pressure sensor unit 202, the third pressure sensor unit 203, the fourth pressure sensor unit 204, the fifth pressure sensor unit 205 and the sixth pressure sensor unit 206;

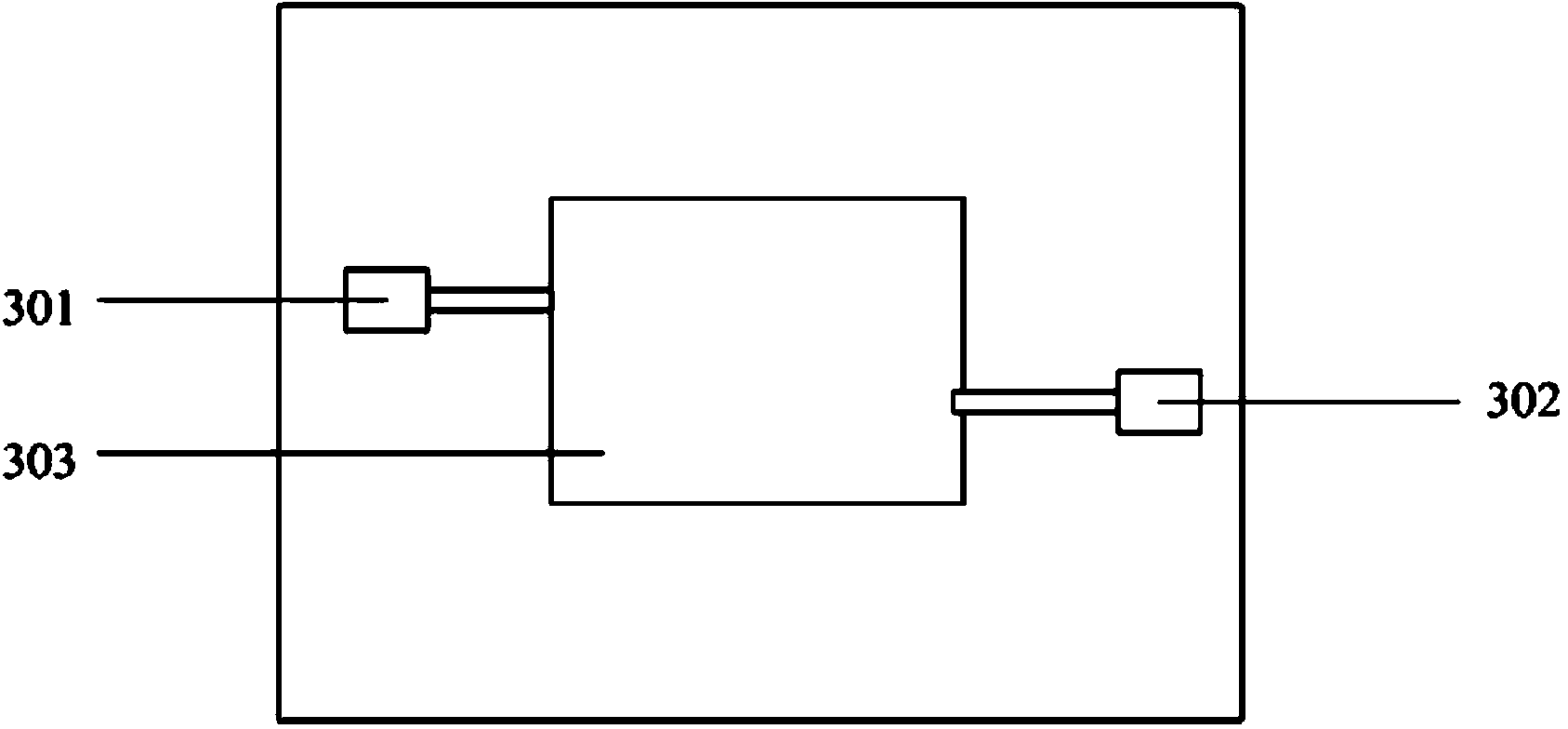

[0018] Such as figure 2 As shown, the first pressure sensor unit 201, the second pressure sensor unit 202, the third pressure sensor unit 203, the fourth pressure sensor unit 204, the fifth pressure sensor unit 205 and the sixth pressure sensor unit 206 respectively include upper electrodes 301 (the upper electrodes of the first pressure sensor unit 201, the second pressure sensor unit 202, the third pressure sensor uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com