Vertical structure of anisotropic magnetoresistive sensor and its manufacturing method

An anisotropic magnetic and vertical structure technology, applied in the field of magnetic sensors, can solve the problems of high processing cost of AMR sensor system, no device structure and manufacturing method, difficult microelectronic processing technology, etc., and achieves wide applicability, simple structure, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

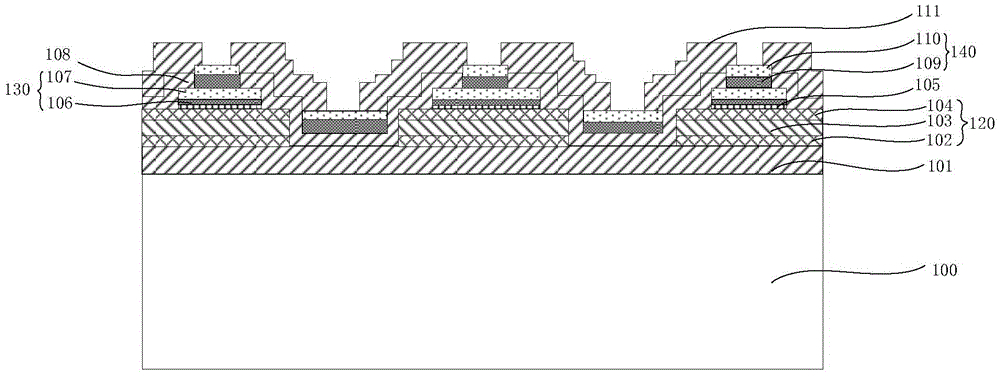

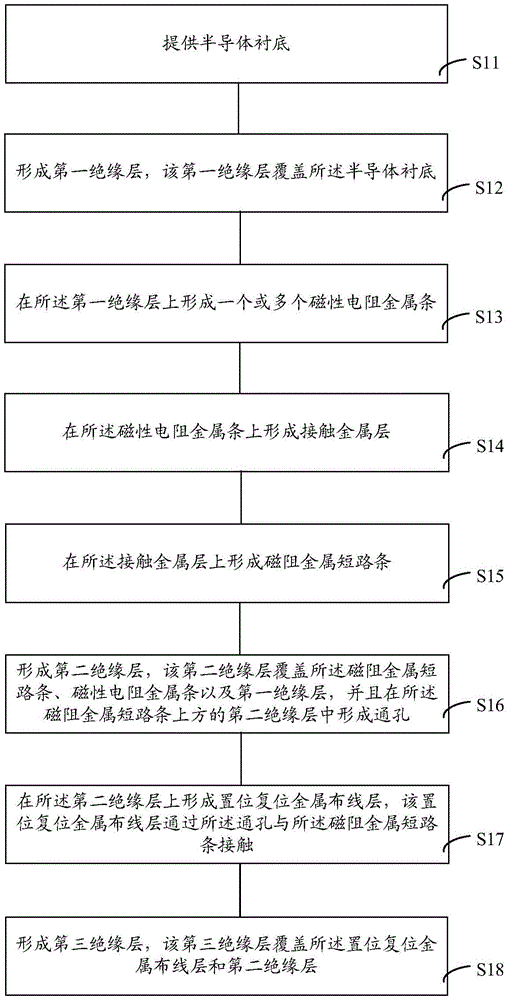

[0062] refer to figure 1 , the vertical structure of the anisotropic magnetoresistive sensor in this embodiment includes: a semiconductor substrate 100; a first insulating layer 101 covering the semiconductor substrate 100; one or more magnetoresistive metal strips 120 located on the first insulating layer 101; The contact metal layer 105 is located on the magnetoresistance metal strip 120; the magnetoresistance metal short-circuit bar 130 is located on the contact metal layer 105; the second insulating layer 108 covers the magnetoresistance metal short-circuit bar 130, the magnetoresistance metal strip 120 and the first insulating layer Layer 101, and the second insulating layer 108 has a through hole above the magnetoresistive metal shorting bar 130; the set reset me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com