Printed paper microfluidic chip and fabrication method

A paper-based microfluidic and printing technology, which is applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of large impact on substrate materials, high energy consumption, and inability to process, and achieve improved Production efficiency, cost reduction, and complexity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

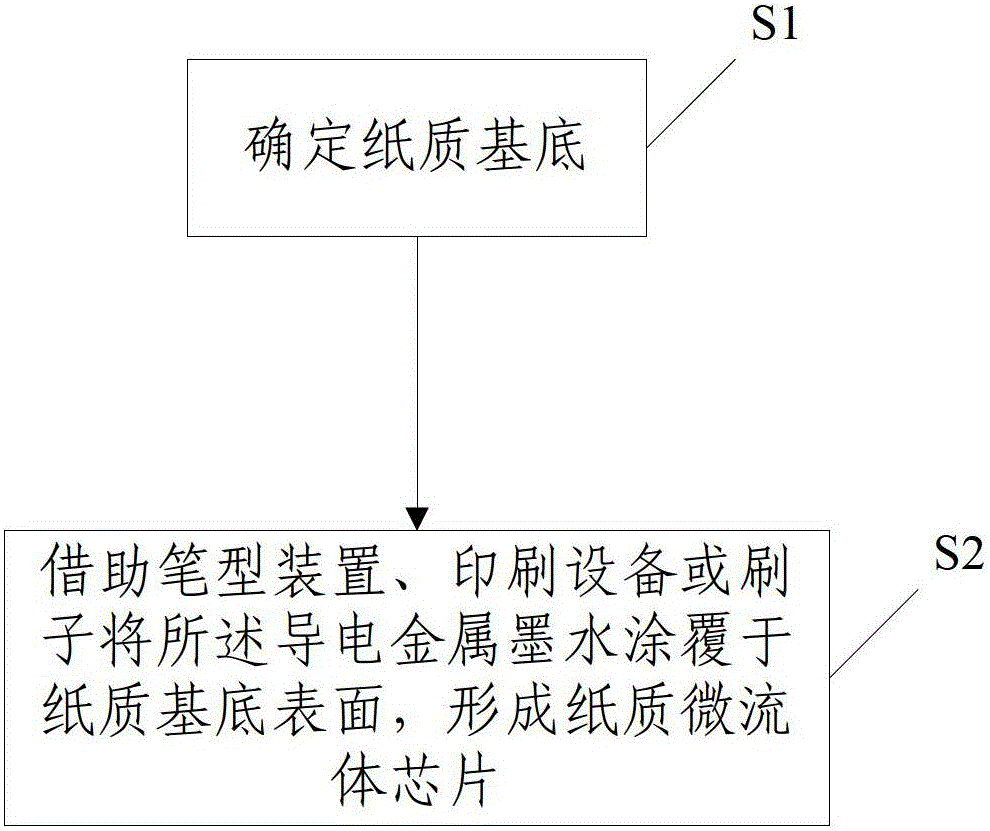

Method used

Image

Examples

Embodiment 1

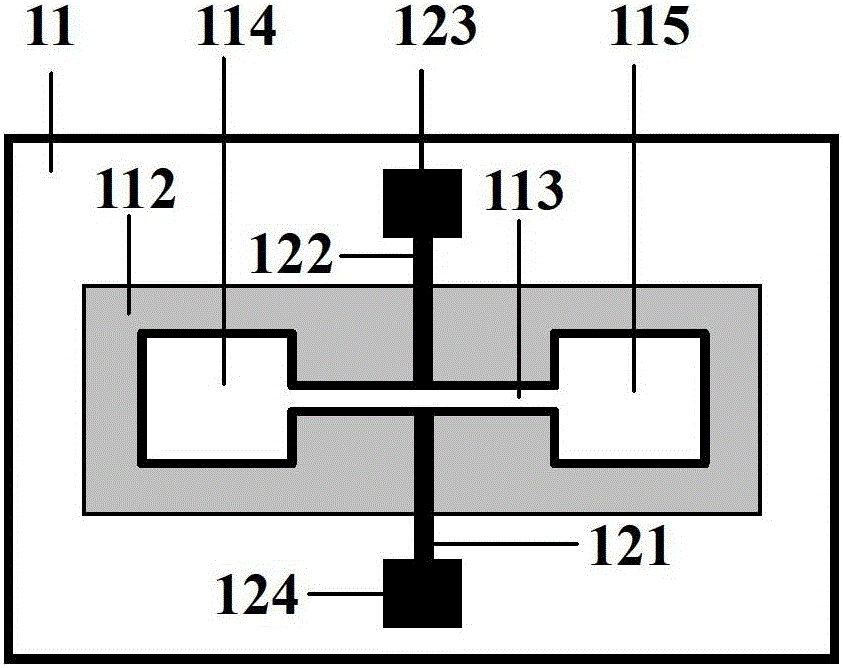

[0036] figure 2It is a schematic structural diagram of a printed paper microfluidic chip in Example 1 of the present invention, as figure 2 As shown, in this embodiment, the microfluidic chip substrate 11 is made of paper with a thickness of 0.5mm, and its part is infiltrated with paraffin to form figure 2 In the rectangular paraffin paper part 112, on this basis, a metal hard mold is used to emboss a flow channel 113 with a width of 0.1 mm on the paraffin paper part 112, and a fluid inlet pool 114 and an outlet pool 115 of 2 mm × 2 mm at both ends of the flow channel After that, at room temperature, the conductive metal ink (liquid gallium) 121 containing 0.25wt% gallium oxide is vertically coated on the upper and lower sides of the flow channel 113 in the paraffin paper 112 in the form of a line, forming an electrode 121 with a width of 0.5mm , 122, where the ends of the two electrodes are terminals 123, 124 of 2mm×2mm. Thus, the fabrication of the flow cytometry chip o...

Embodiment 2

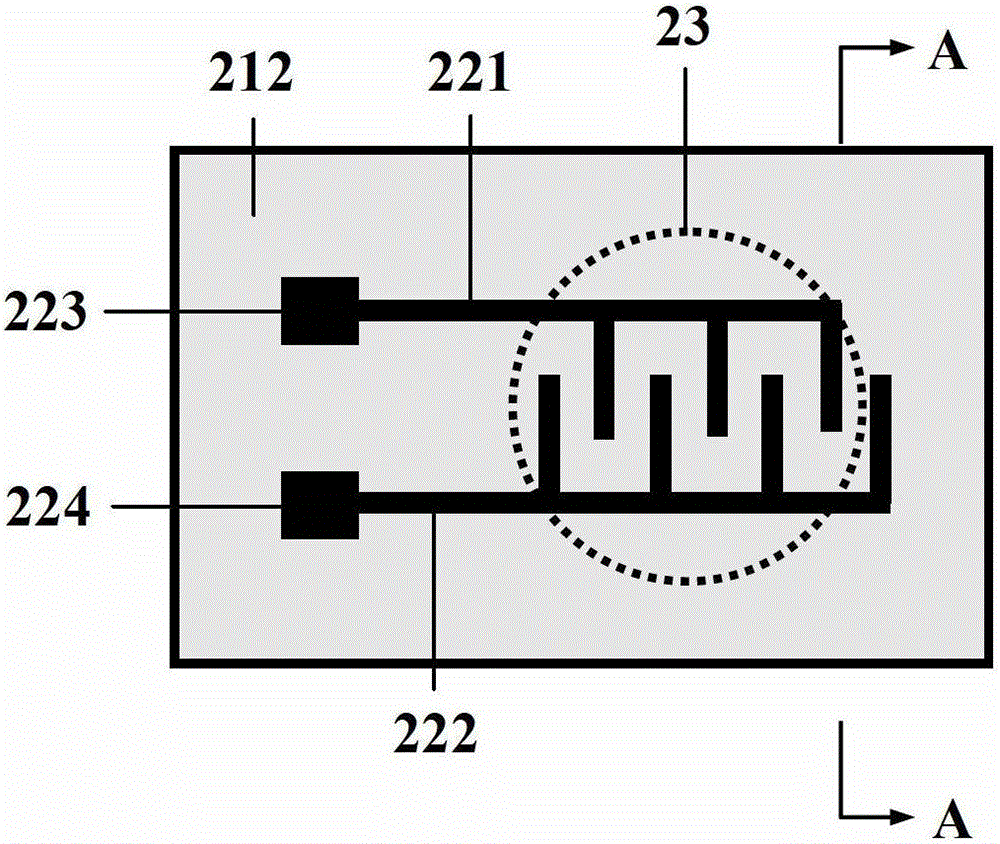

[0038] Figure 3a It is a schematic structural diagram of a printed paper microfluidic chip in Example 2 of the present invention, Figure 3b for Figure 3a A-A sectional view, such as Figure 3a-3b As shown in Fig. 1, the liquid drop directly titrated on the substrate is measured by using a channelless structure, and the electrode shape adopts a toothed structure to improve sensitivity. In this embodiment, the microfluidic chip substrate 212 is made of paper with a thickness of 0.5mm, which is completely infiltrated with paraffin; after that, at room temperature, the conductive metal ink (liquid gallium) containing 0.25wt% gallium oxide is coated in a tooth-shaped staggered form. Cover the surface of paraffin paper to form tooth-shaped electrodes 221 and 222 with a line width of 0.5 mm, and the ends of the two electrodes are terminals 223 and 224 of 2 mm×2 mm. Thus, the fabrication of the droplet fluid detection chip of this embodiment is completed. When in use, once the ...

Embodiment 3

[0040] Figure 4 It is a schematic structural diagram of a printed paper microfluidic chip in Example 3 of the present invention, as Figure 4 As shown, the difference between Embodiment 1 and Embodiment 2 is that the function of the electrode here is to exist as a heating film. In this embodiment, the microfluidic chip substrate 31 uses paper with a thickness of 0.5 mm, and its part is infiltrated with paraffin. On this basis, a metal hard mold is used to imprint a width of 0.1 mm on the paraffin paper part in a meandering form as shown in the figure. The flow channel 312 of mm, the two ends of the flow channel are a fluid inlet pool 313 and an outlet pool 314 of 2mm×2mm; after that, a metal ink (liquid gallium) 321 containing 0.25wt% gallium oxide is applied in the form of a thin film at room temperature Cover the corresponding parts of the paraffin paper, thereby forming three-stage heating films 33, 34, 35 with a width of 5mm, respectively, and the respective heating powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com