Method for growing noble metal nanocrystals on the surface of graphene oxide

A technology of noble metal nanocrystals and graphene surfaces, which can be used in metal material coating technology, liquid chemical plating, coating, etc., and can solve the problems of lack of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

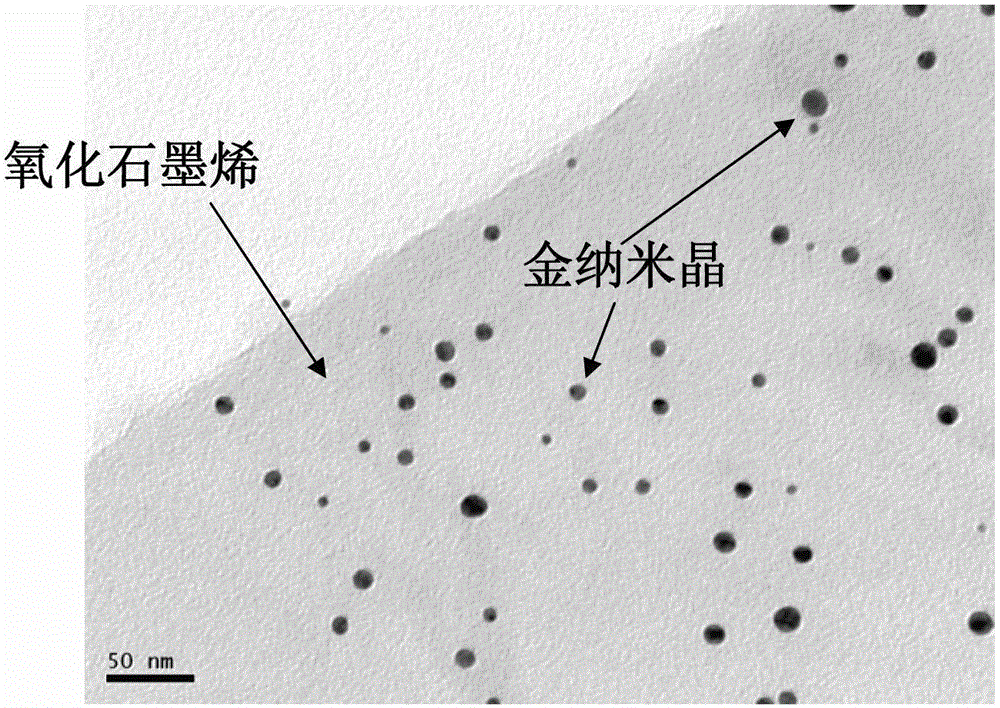

[0031] Embodiment 1: grow gold nanocrystal on graphene oxide surface

[0032] a) Measure 10 ml of oleylamine and stir at 120° C. for 10 minutes;

[0033] b) adding 0.1 gram of graphene oxide and stirring for 30 minutes, so that graphene oxide is evenly dispersed in oleylamine;

[0034] c) add 0.04 gram of chloroauric acid tetrahydrate (HAuCl 4 4H 2 O), continue to stir and react for 10 minutes;

[0035] d) raising the temperature to 180°C, and continuing to stir and react at 180°C for 10 minutes;

[0036] e) The product was centrifuged at high speed (12000rpm, relative centrifugal force about 13000×g) for 5 minutes to separate the solid product from oleylamine, and washed the product three times with 30 ml of n-hexane;

[0037] f) drying the product under air to obtain a graphene oxide product with gold nanocrystal support.

[0038] The product prepared by the above steps was characterized by a transmission electron microscope. The results showed that a large number of go...

Embodiment 2

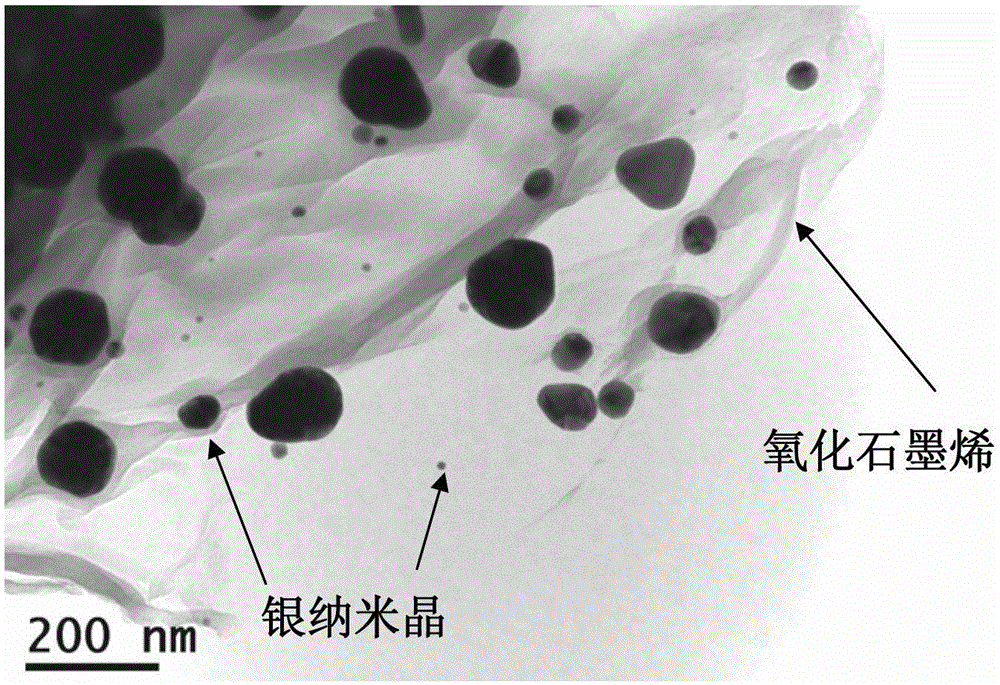

[0039] Embodiment 2: grow silver nanocrystals on the surface of graphene oxide

[0040] a) Measure 10 ml of oleylamine and stir at 120° C. for 10 minutes;

[0041] b) adding 0.1 gram of graphene oxide and stirring for 30 minutes, so that graphene oxide is evenly dispersed in oleylamine;

[0042] c) Add 0.02 grams of silver nitrate (AgNO 3 ), continue to stir and react for 10 minutes;

[0043] d) raising the temperature to 180°C, and continuing to stir and react at 180°C for 10 minutes;

[0044] e) continue to raise the temperature to 220°C, and continue to stir and react at 220°C for 10 minutes;

[0045] f) The product was centrifuged at high speed (12000rpm, relative centrifugal force about 13000×g) for 5 minutes to separate the solid product from oleylamine, and washed the product three times with 30 ml of n-hexane;

[0046] g) drying the product under air to obtain a graphene oxide product with silver nanocrystal loading.

[0047] The product prepared by the above step...

Embodiment 3

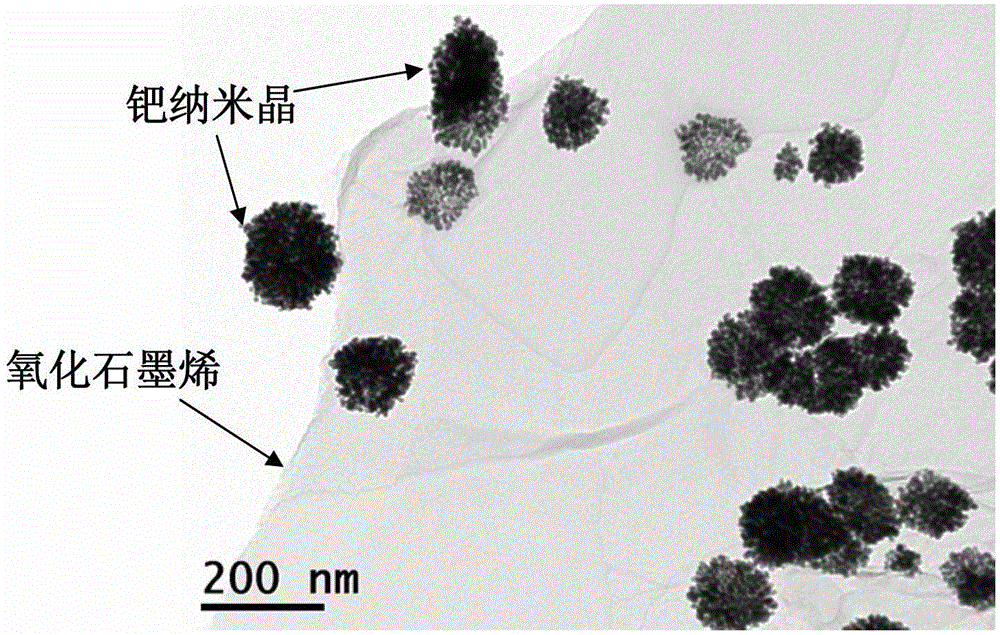

[0048] Embodiment 3: grow palladium nanocrystal on graphene oxide surface

[0049] a) Measure 10 ml of oleylamine and stir at 120° C. for 10 minutes;

[0050] b) adding 0.1 gram of graphene oxide and stirring for 30 minutes, so that graphene oxide is evenly dispersed in oleylamine;

[0051] c) add 0.02 gram of palladium chloride (PdCl 2 ), continue to stir and react for 10 minutes;

[0052] d) raising the temperature to 180°C, and continuing to stir and react at 180°C for 10 minutes;

[0053] e) continue to raise the temperature to 220°C, and continue to stir and react at 220°C for 10 minutes;

[0054] f) The product was centrifuged at high speed (12000rpm, relative centrifugal force about 13000×g) for 5 minutes to separate the solid product from oleylamine, and washed the product three times with 30 ml of n-hexane;

[0055] g) drying the product under air to obtain a graphene oxide product with palladium nanocrystal loading.

[0056] The product prepared by the above steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com