Composite telescopic crane arm with metal ends on tubular segments and crane comprising said arm

A telescopic boom and crane technology, applied in the field of cranes and telescopic booms, to achieve the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

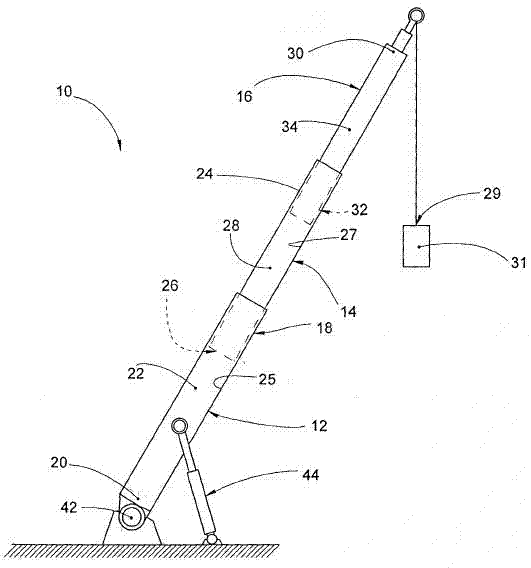

[0062] With reference to the accompanying drawings, a telescopic jib according to the invention is indicated with numeral 10 and can be used in a crane for lifting loads (only in figure 1 shown schematically in ), for example in the field of architecture or construction.

[0063] The telescoping arm 10 includes a plurality of sections 12, 14, 16, one of which slides within the other, which can be extended linearly to assume an extended operating state, or one in a non-operating state or when the machine is stopped. Another inner retraction.

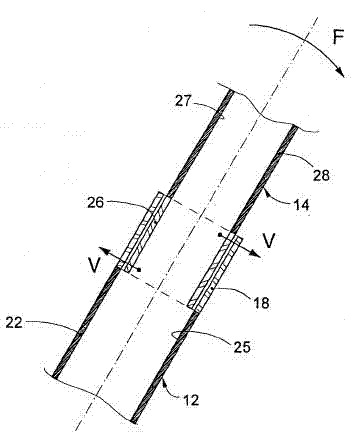

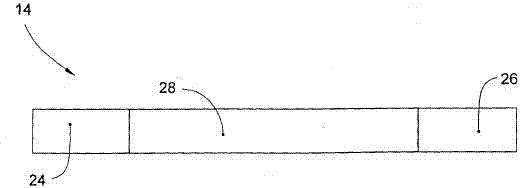

[0064] The segments 12, 14, 16 have a box-like cross-section, inside which are provided respective axial positioning seats 25, 27 to accommodate the segments in their retracted positions.

[0065] The reciprocating portions of the segments 12, 14, 16 are of cooperating shape and size so as to be able to be inserted axially into the respective axially locating bases 25, 27, in a generally telescoping configuration, when possible or desire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com