Primary cleaning screen with electromagnet

An electromagnet, primary cleaning technology, applied in magnetic separation, solid separation, feed and other directions, can solve the problems of incomplete cleaning, difficult operation, weak magnetism, etc., and achieve convenient maintenance, low cost, and easy production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

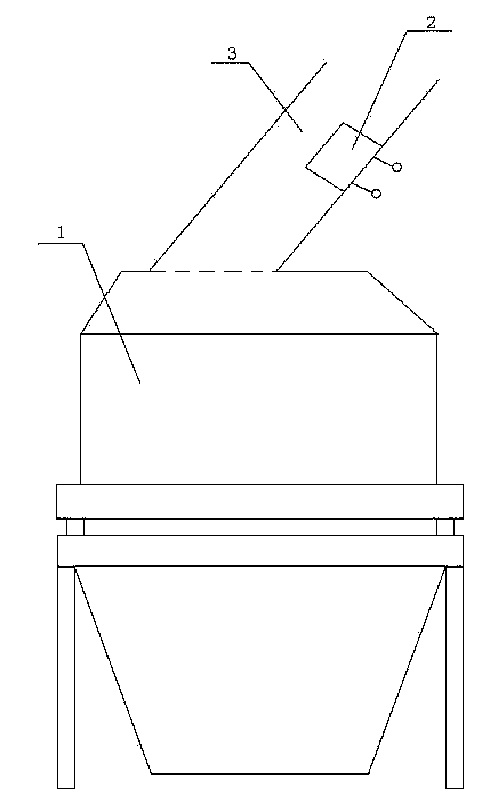

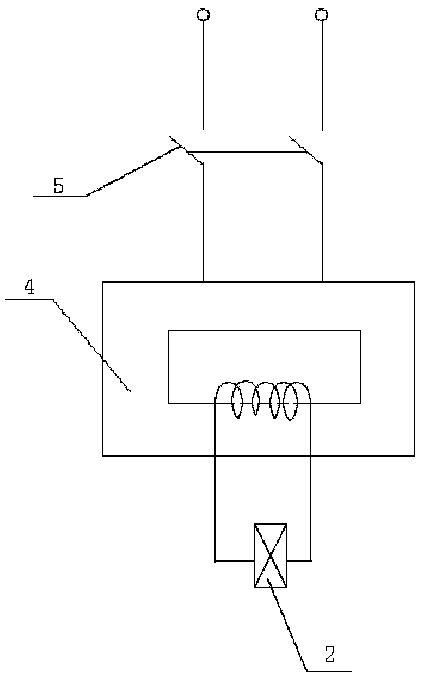

[0013] like figure 1 , figure 2 As shown, the primary cleaning screen with an electromagnet includes a primary cleaning screen 1 with a feeding pipe 3 on the top. An electromagnet 2 is arranged in the feed pipe 3; a wire is wound on the electromagnet 2, and the wire is connected with a transformer 4 with a power of 15W; the transformer 4 is connected with a 220V lighting power supply through a bipolar switch 5.

[0014] During use, connect 220V lighting power supply, the lighting electricity of 220V is converted into the direct current of 36V by transformer 4, at this moment electromagnet has just produced magnetic force, when raw material passes through feed pipe, just can suck the ironware impurity.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap