Method and device for removing glue from anilox roller of coating machine

A technology of anilox roller and coating machine, which is applied to the device and coating of surface coating liquid, which can solve the problems affecting product quality and wire drawing, and achieve the effect of simple processing, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

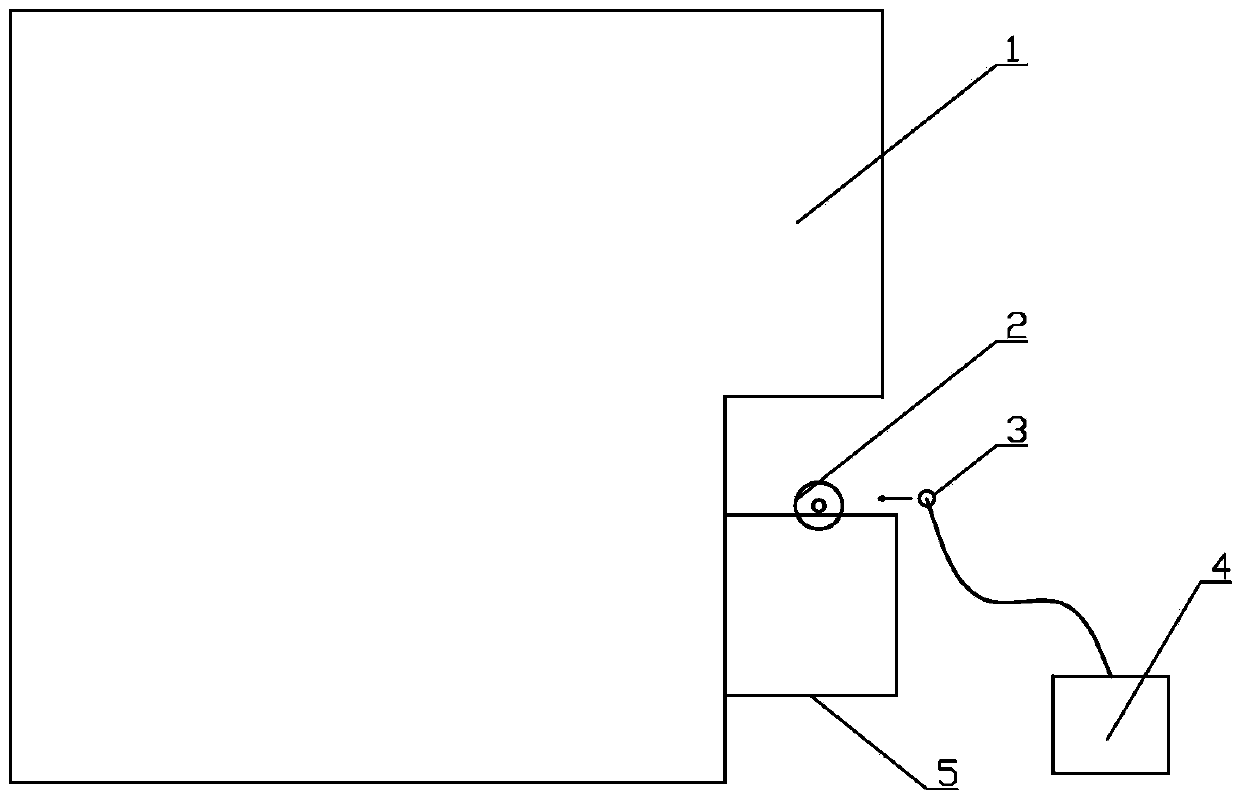

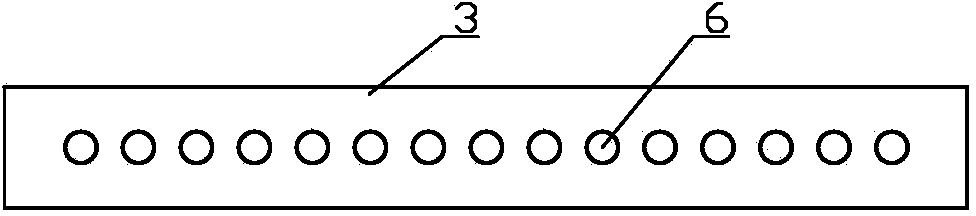

[0015] Such as figure 1 , figure 2 As shown: the body 1 of the coating machine is provided with an anilox roller 2 and a glue tank 5, and a parallel air outlet pipe 3 is arranged on the outside of the anilox roller 2, and a row of multiple air outlets is arranged on the air outlet pipe 3. Namely the circular hole 6.

[0016] When the present invention is used, the air pump 4 pressurizes, and the air outlet pipe 3 blows cold air at the separation place between the anilox roller 2 and the film, so that the generated wires are quickly air-dried. With the rotation of the anilox roller 2, the air-dried wires break and fall into the net. In the glue tank 5 below the grain roller 2, it is melted when heated in the glue tank 5 and continues to be used.

Embodiment 2

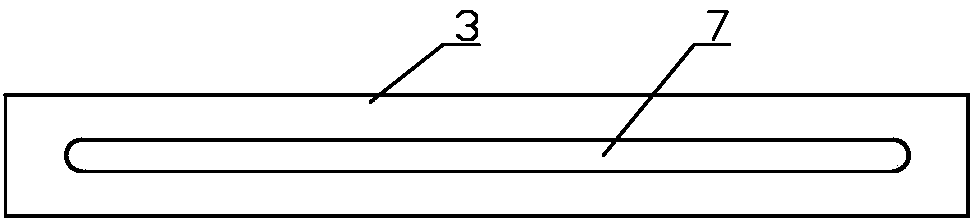

[0018] Such as figure 1 , image 3 Shown: the air outlet pipe 3 is provided with an air outlet, i.e. a long hole 7, and the others are the same as in Embodiment 1.

[0019] The present invention is not limited to the above embodiments, and other forms can be used as the air outlet, as long as the air can be evenly sent to the anilox roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com