Cutter specially for electronic connector housing processing

A technology for electronic connectors and shells, which is applied in the field of special tools for processing electronic connector shells. It can solve the problems of irregular shell shapes, difficult processing, time-consuming and labor-intensive processing, etc., and achieve the effect of improving processing efficiency and quality and reducing the number of tool changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The present invention will be further described in detail below through specific embodiments.

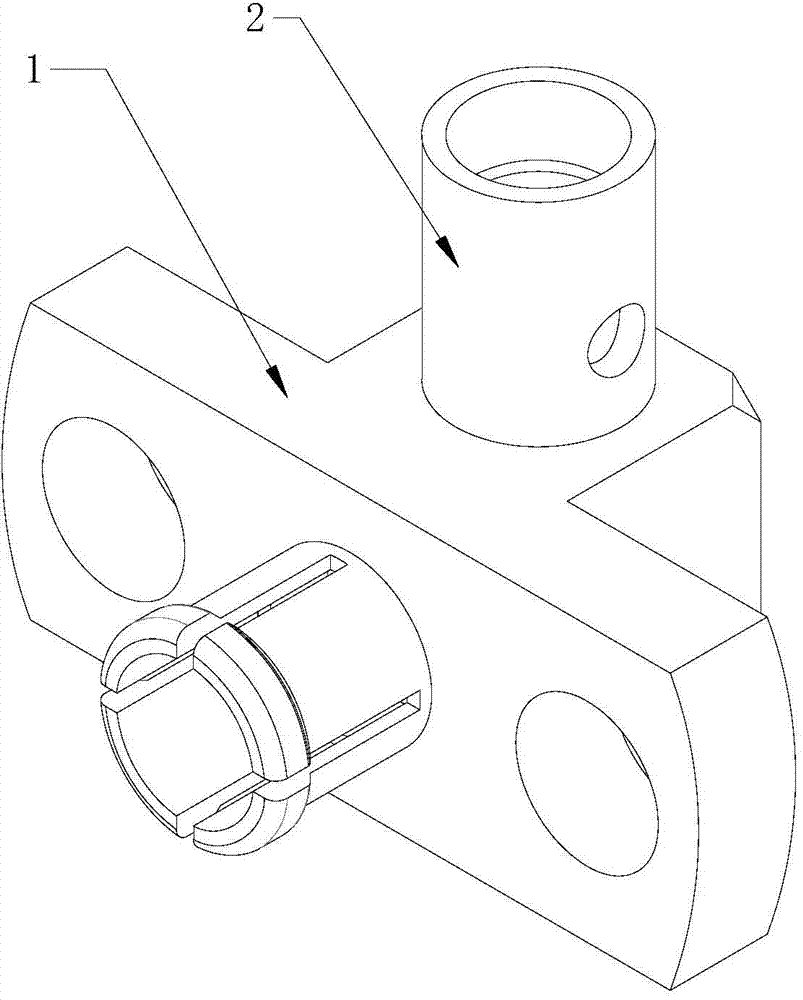

[0013] figure 1 The housing of the electronic connector is shown in the figure, and the housing comprises a T-shaped body 1 and two cylinders 2 whose axial directions are at an angle of 90°, wherein, what the tool 3 of the present invention needs to process is the T-shaped body 1 and the two cylinders 2, The other grooving and punching of the housing is done by other cutters.

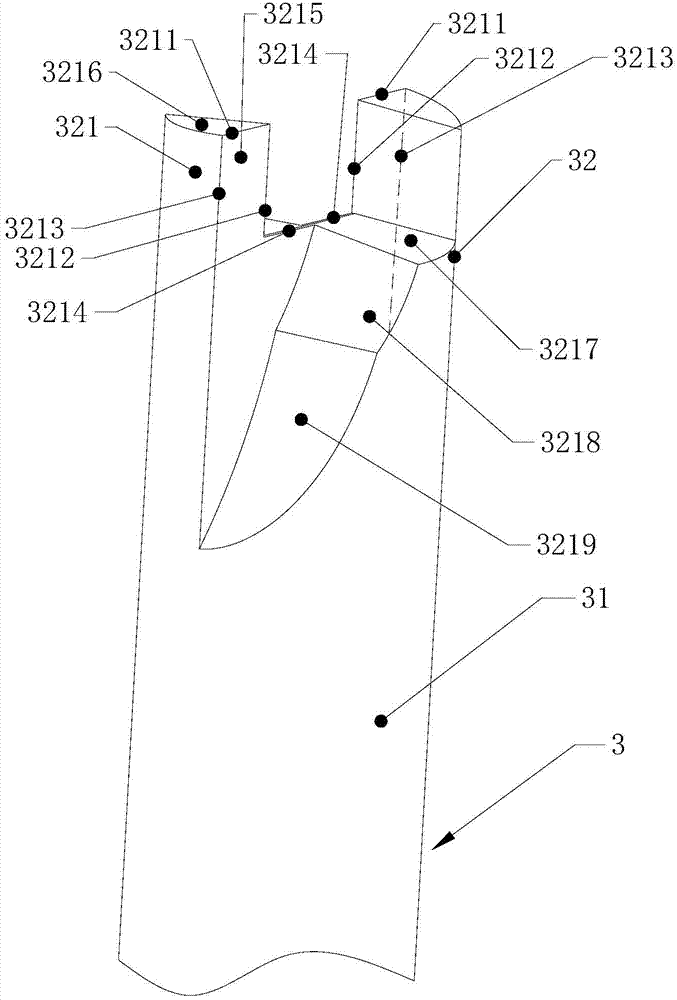

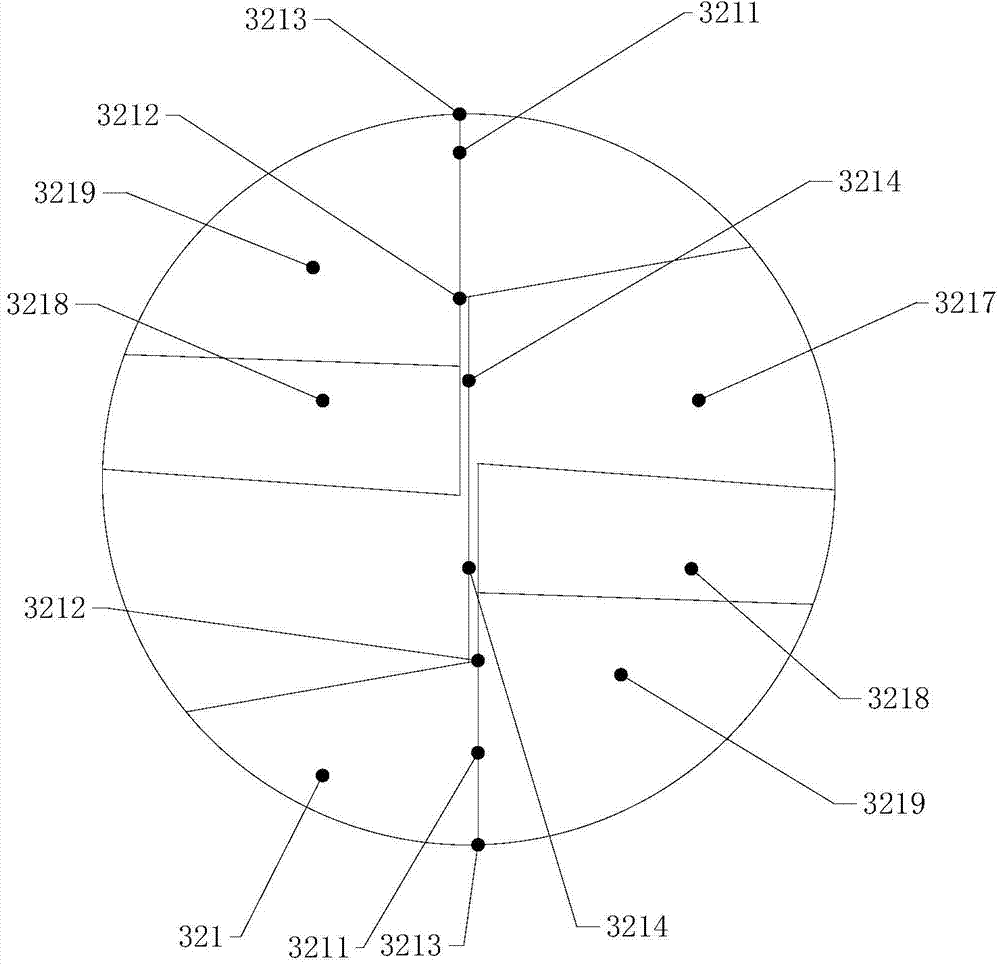

[0014] like figure 2 , 3 As shown, a special tool 3 for machining an electronic connector housing includes a tool head 32 and a tool shank 31. The tool head 32 includes two cutting columns 321 circumferentially arrayed with the central axis of the tool shank 31. The cutting columns 321 are composed of cylindrical The entity constituted by the plane, the rotation upstream side plane, and the rotation downstream side plane 3215, the rotation upstream side and the rotation downstream side mentioned he...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap