Mosaic wood cold press

A technology of cold press and wood joining, applied in the direction of veneer press, plywood press, wood processing equipment, etc., which can solve the problems of increasing production cost, plate size limited press size, large press, etc., to achieve improvement Production efficiency, stress relief, and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

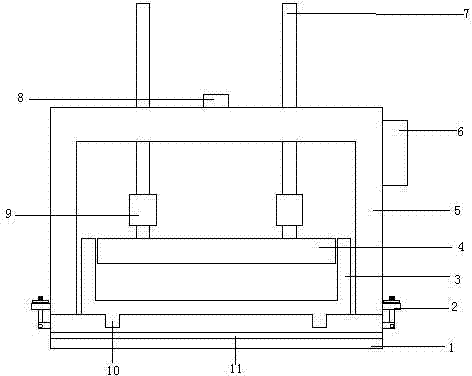

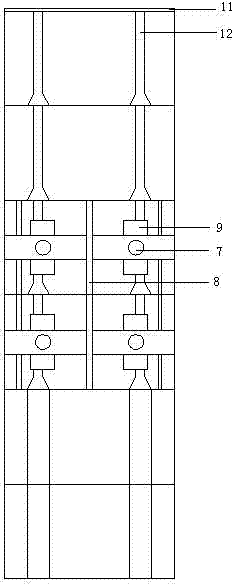

[0015] see figure 1 , the wooden cold press of the present invention includes a base 1, a support 5 and a control box 6, the base 1 and the support 5 are in a detachable structure and fixed by means of a connector 2, and the main hydraulic rod 7 is arranged on the support 5, the main The lower end of the hydraulic rod 7 is connected to the upper platen 4, the tray 3 is supported on the base 1, a slide rail 12 is arranged on the base 1, a protrusion 10 is arranged on the lower part of the tray 3, and the tray 3 is fixed by means of the protrusion 10 and the slide rail 12 On the base 1 and can move forward and backward in the slide rail 12. When manufacturing plates of different sizes, the appropriate number of trays and supports can be selected. see figure 2 1. After loading the material on the tray outside the bracket, push the assembled tray into the bracket alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com