Method for producing aromatic diol mono(meth)acrylate

An aromatic diol, acrylate technology, applied in the preparation of carboxylate, the preparation of organic compounds, organic chemical methods, etc., can solve the problem of insufficient, unsatisfactory purity, and a large amount of secondary by-products of aromatic diol, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

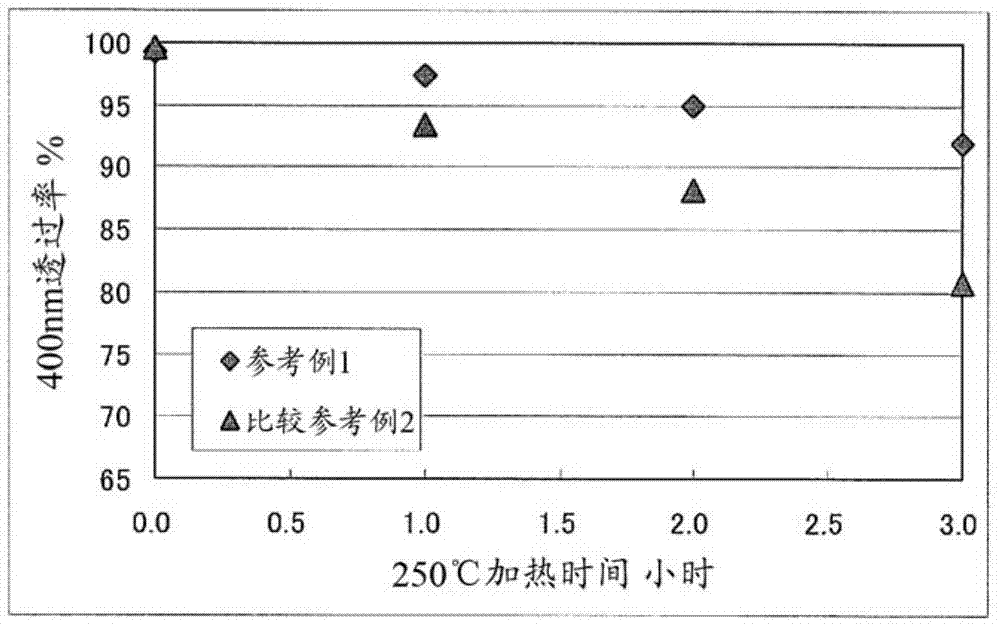

[0045] The aromatic diol mono(meth)acrylate obtained by the preparation method of the present invention is solid at normal temperature, and has the following characteristics: it is relatively stable to heat or light; and its polymerizability is the same as that of general (methyl) Acrylics are equal.

[0046] If the aromatic diol mono(meth)acrylate obtained by the production method of the present invention is used to synthesize a polymer, it is possible to obtain a high Tg polystyrene with excellent solvent solubility, alkali solubility, transparency, heat discoloration resistance, etc. , High thermal decomposition temperature, high refractive index polymer. Therefore, it can be applied to alkali-developing photoresists used in semiconductor manufacturing, display elements, printing plate-making materials, etc., protective films that require transparency and thermal discoloration resistance, and the like. In addition, it is also useful as a curing agent for epoxy resins and t...

Embodiment 1

[0064] Synthesis of 4-Hydroxyphenyl Methacrylate

[0065] Put 100 parts by mass of hydroquinone, 235 parts by mass of methacrylic acid, and 4 parts by mass of p-toluenesulfonic acid into a 1L detachable flask equipped with a condenser, a thermometer, and a stirring paddle, and start at 120°C while blowing in air. reaction. When the reaction reached equilibrium and the composition of the product was constant, the reaction was continued while performing vacuum distillation at -80 kPa so that the water content in the system was maintained at 0.2% by mass or less. When the ratio of 4-hydroxyphenyl methacrylate reached 49.9% of the moles of hydroquinone charged, the system was returned to normal pressure and cooled to complete the esterification reaction. The composition ratio, color tone, and turbidity are all shown in Table 1.

Embodiment 2

[0067] Synthesis of 4-Hydroxyphenyl Methacrylate

[0068] 100 parts by mass of hydroquinone, 235 parts by mass of methacrylic acid, and 10 parts by mass of strongly acidic ion-exchange resin Amberlyst15.DRY manufactured by Organo Co., Ltd. were put into a condenser and a thermometer. , a 1L detachable flask with a stirring paddle, and start the reaction at 120°C. When the reaction reached equilibrium and the composition of the product was constant, the reaction was continued while performing vacuum distillation at -80 kPa so that the water content in the system was maintained at 0.2% by mass or less. When the ratio of 4-hydroxyphenyl methacrylate reached 56.8% of the moles of hydroquinone charged, the system was returned to normal pressure and cooled to complete the esterification reaction. The composition ratio, color tone, and turbidity are all shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com