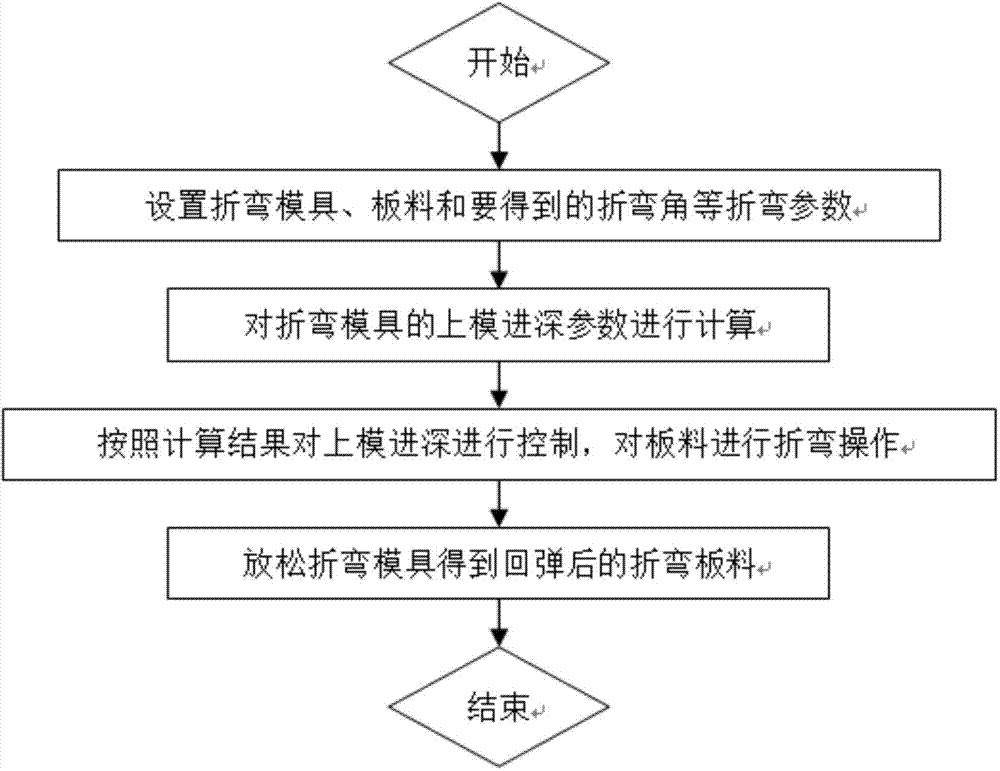

Method for controlling depth of sliding block of upper die of bending machine

A control method and bending machine technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inaccurate bending, expensive imported equipment, etc., to save money, high accuracy, The effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

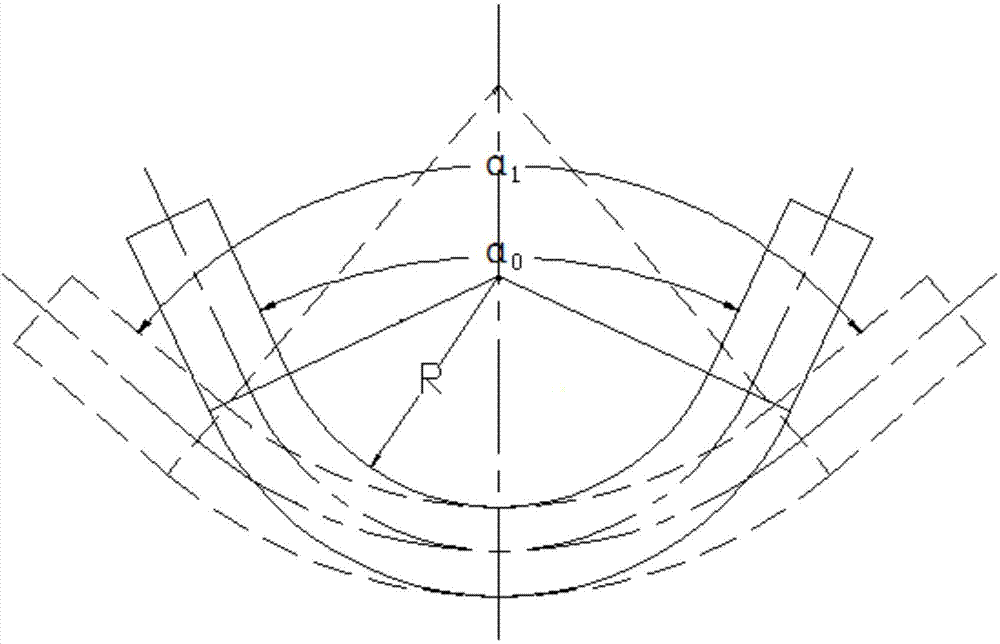

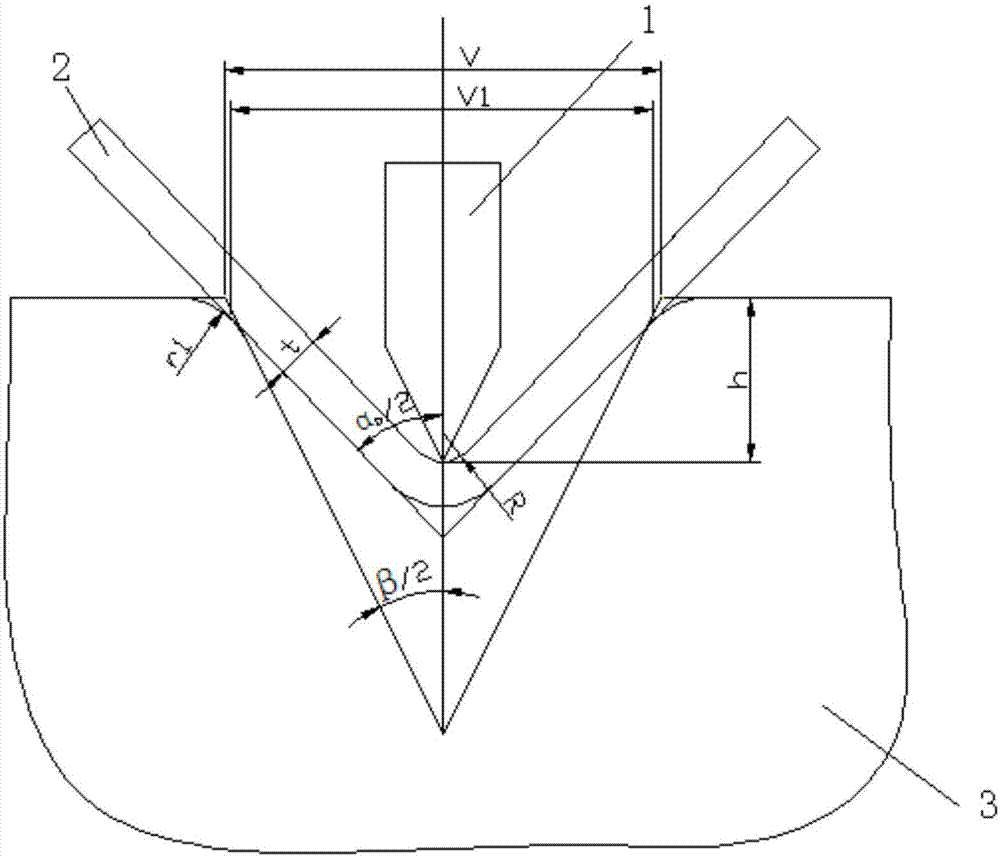

[0039] First obtain the relevant parameters of the bending sheet 2 and the mold as follows: the thickness of the bending sheet 2 is t=1.4mm, the material is Q235, the elastic modulus E=200000MPa, and the strength limit σ b =450MPa, the nominal opening of the lower mold of the bending mold V=12mm, the V-shaped angle of the V-shaped groove β=86°, the fillet radius r at the V-shaped groove of the lower mold 3 1 =1mm. Since V / t=8.6, 6t≤V≤12t is satisfied, so the method of the present invention can be used.

[0040] Set the target bending angle α 1 =102°.

[0041] On a CNC bending machine, there are generally control units, motors, hydraulic systems, upper die slider 1 and lower die 3, in which the control unit sends motor signals to drive the motor, and the motor controls the upper die slider through the hydraulic system 1 moves up and down, and a position measuring se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap