Turbo charger control system and control method

A turbocharger and control system technology, applied in electrical control, engine control, machine/engine, etc., can solve the problems that exhaust gas cannot be restored and purified, exhaust flow heat loss, etc., to solve the problem of insufficient engine boost, effective Effects of using and preventing chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

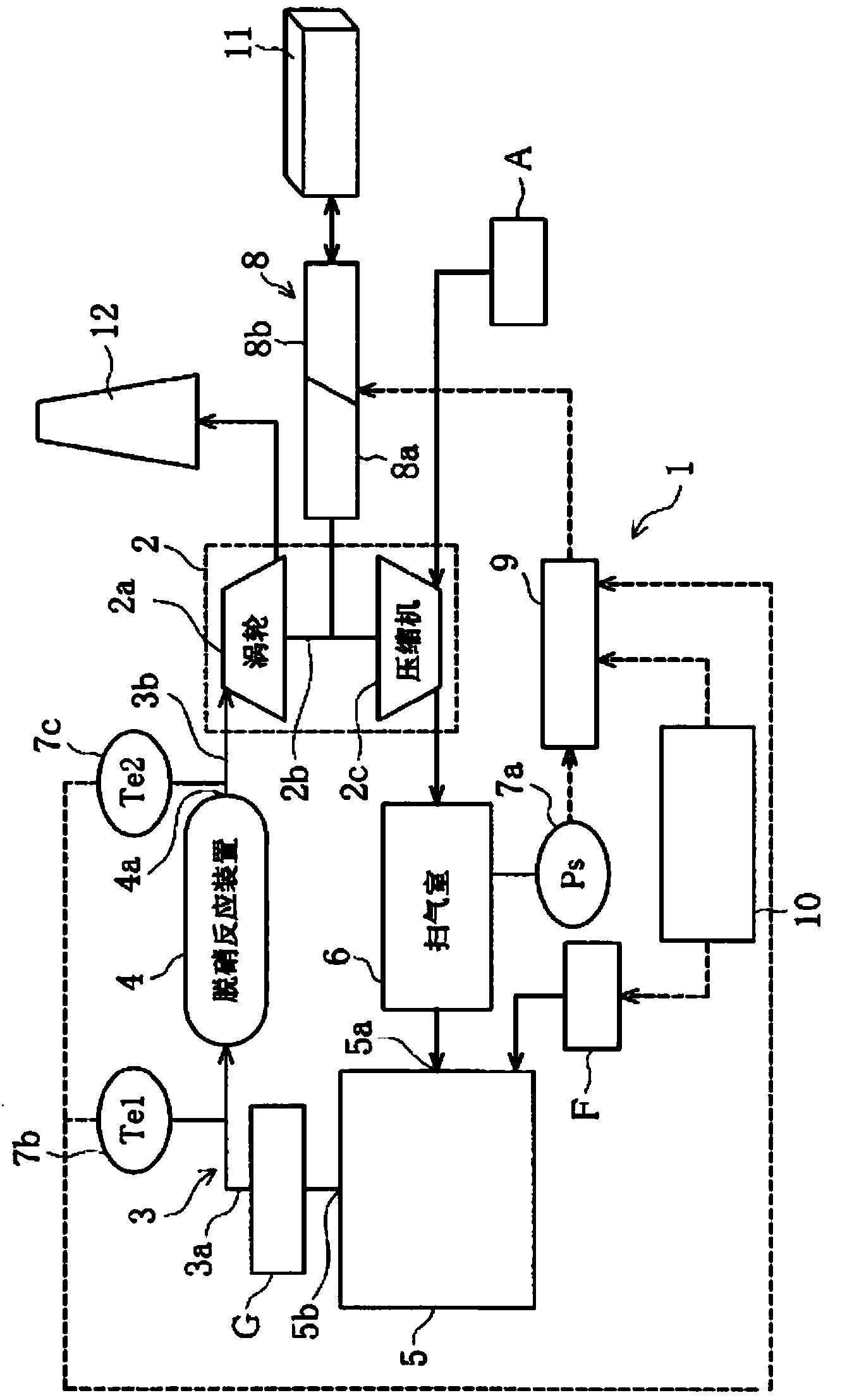

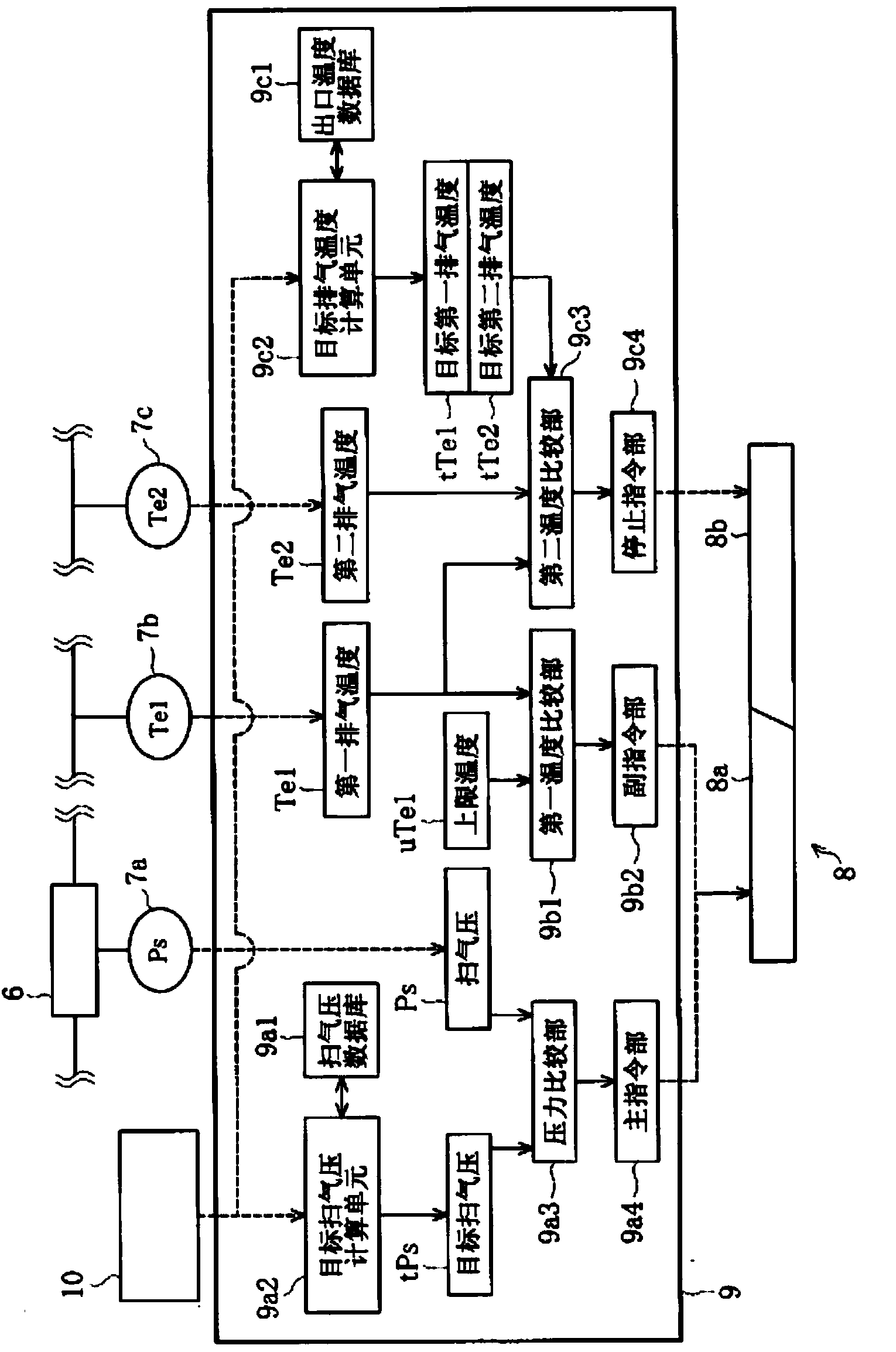

[0054] Such as figure 2 As shown, the control device 9 includes at least: a target sweep air pressure calculation unit 9a2, which accesses the sweep air pressure database 9a1, and obtains the target sweep air pressure tPs based on the engine revolution data acquired from the revolution control device 10; and a pressure comparison unit 9a3, Used to compare the sweep air pressure Ps of the scavenging chamber 6 detected by the pressure gauge 7a and the target sweep air pressure tPs obtained by the target sweep air pressure calculation unit 9a2; the main command unit 9a4, which controls the direction of the air based on the comparison result of the pressure comparison unit 9a3 The drive power supplied by the motor 8a simultaneously issues an instruction to the generator 8b to charge the power storage device 11 with the regenerative power of the motor 8a (first embodiment of the present invention).

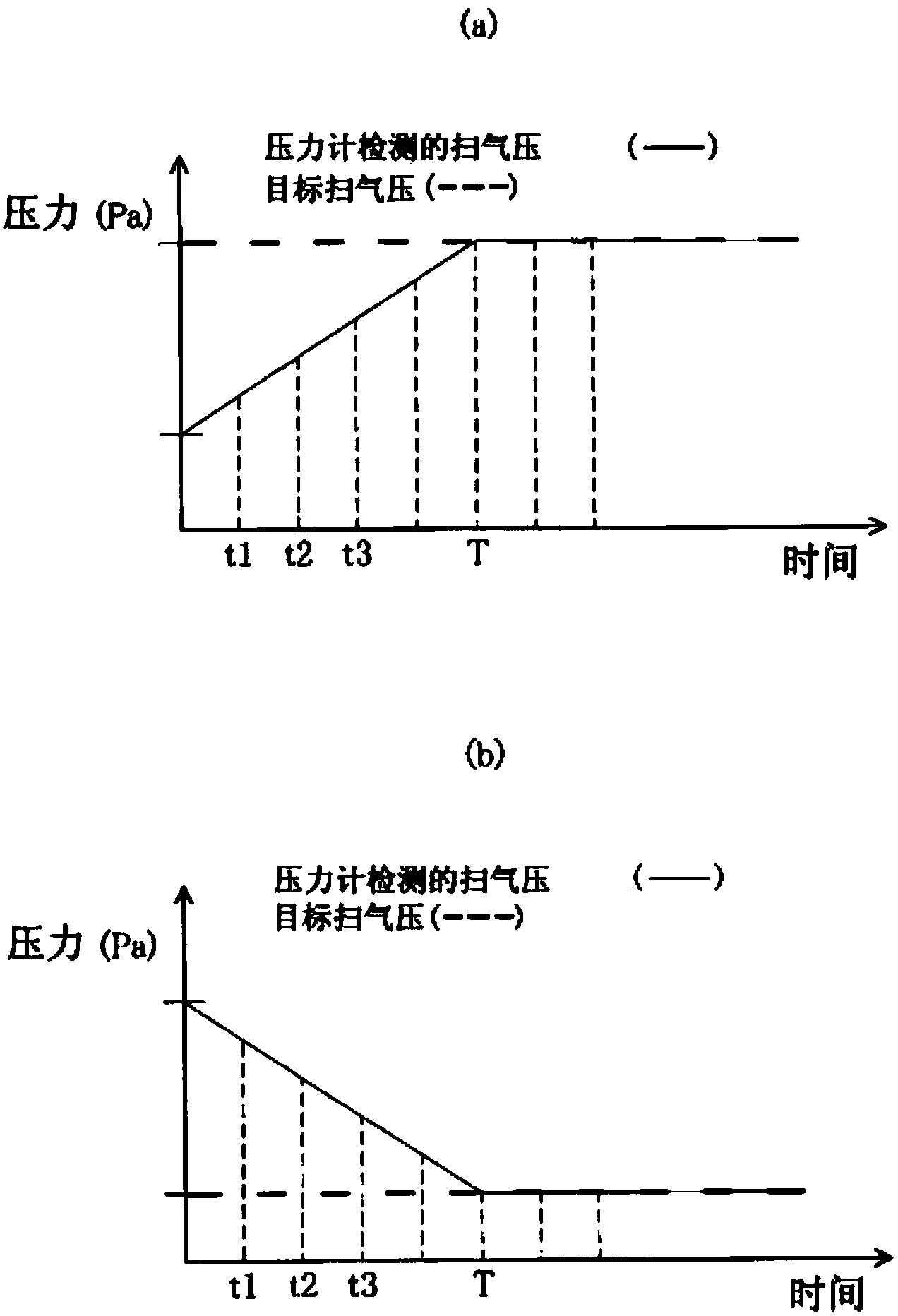

[0055] The scavenging air pressure database 9a1 is a database in which the target sca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap