Method for thermally preparing ferroferric oxide nanoparticle by using low-temperature solvent

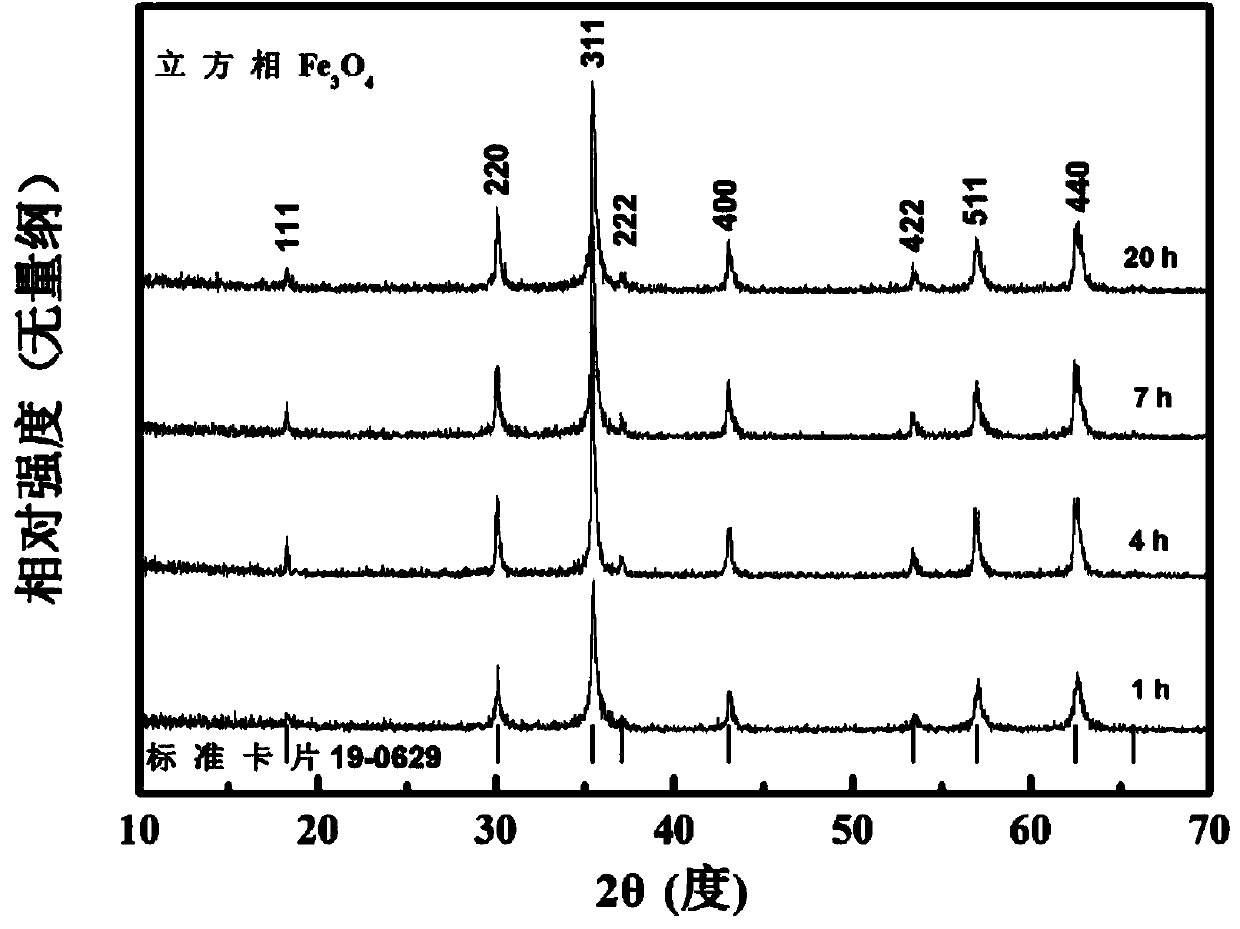

A technology of ferric oxide and nano-microspheres is applied in the field of preparation of inorganic non-metallic materials, which can solve the problems of long reaction time, high synthesis temperature and high operation requirements, and achieves short reaction time, low reaction temperature and easy availability of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

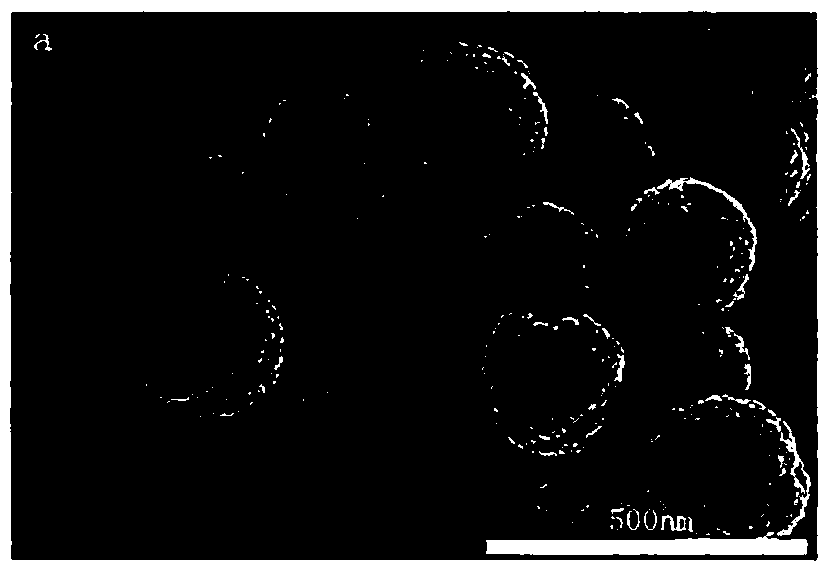

Examples

Embodiment 1

[0027] Step 1: 36mmol of NaOH and 6mmol of triethanolamine are prepared into a mixed solution with 10ml of ethylene glycol with a volume fraction of 75%, and stirred for 10 minutes until NaOH and triethanolamine are completely dissolved, and then the solution is evenly divided into two parts;

[0028] Step 2: Dissolve 1.8mmol ferric chloride in 10ml of ethylene glycol solution with a volume fraction of 75%, and stir for 5 minutes until ferric chloride is completely dissolved in the solution;

[0029] Step 3: Dissolve 1.2mmol of ferrous chloride in 2.5ml of deionized solution, stir for 3 minutes until the ferrous chloride is completely dissolved, then add 7.5ml of ethylene glycol and stir for 2min until the solution turns light green;

[0030] Step 4: Mix the ferric chloride solution and a portion of NaOH solution, and stir for 5 minutes until the solution turns into a light yellow liquid;

[0031] Step 5: Mix the ferrous chloride solution with another NaOH solution, and stir f...

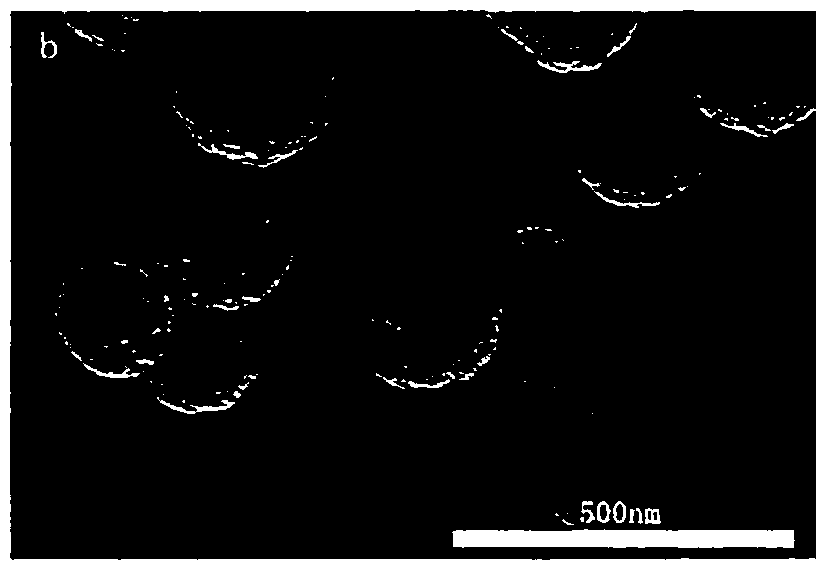

Embodiment 2

[0036] Take 40mmol sodium hydroxide, 6.5mmol triethanolamine, 2mmol ferric nitrate and 1.5mmol ferrous nitrate, and the specific operation steps are the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com