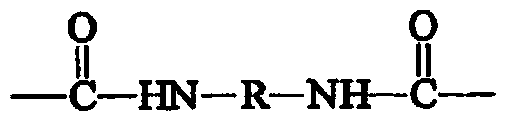

Thermoplastic polyurethane containing structural units of polyester and polyether diols

A thermoplastic polyurethane and structural unit technology, applied in the field of thermoplastic polyurethane, can solve the problems of minimization of water absorption and wet strength, undisclosed TPU's moisture resistance and optical/light transmission properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

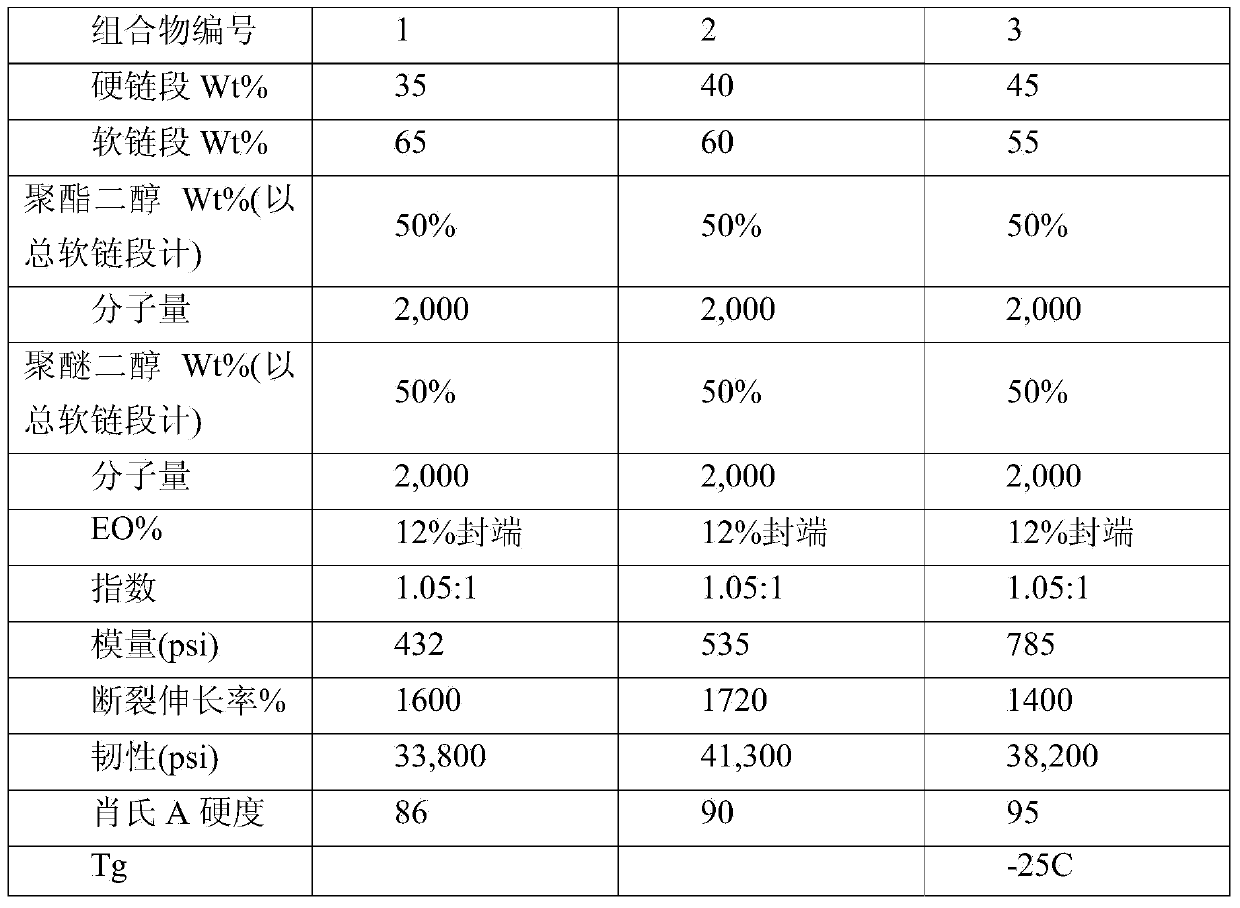

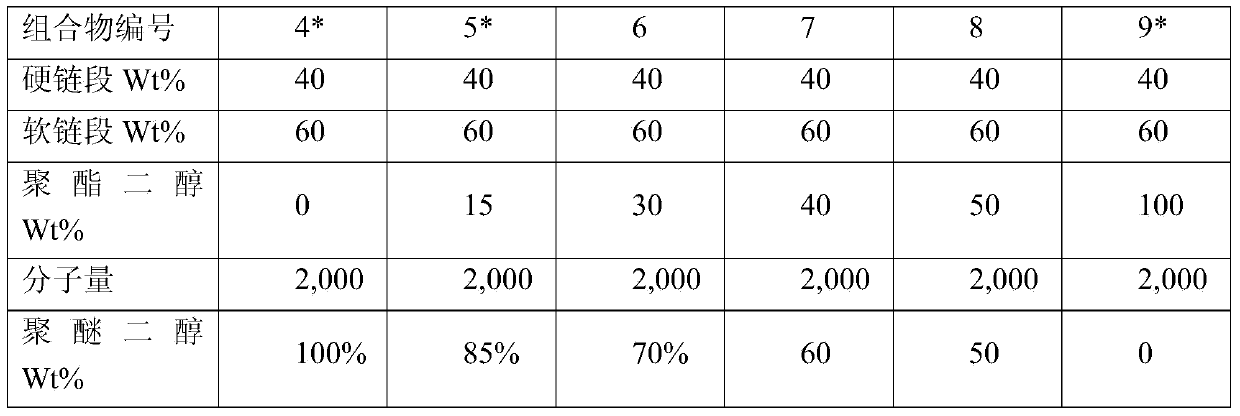

[0060] Test 1-3

[0061] Store MDI in a refrigerator before use (to minimize dimer formation) and allow to return to room temperature under dry conditions. All other materials were dried in a thermal vacuum oven before use. Laboratory synthesis was performed in a Haake disperser (70 cc mixing tank) and the viscosity of the reaction components was determined using a standard torque measuring device. The stoichiometry strictly followed the MDI equivalent excess a.5%. MDI was added to the mixer and heated to 110°C to melt the MDI. The diol or diol blend and a small amount of catalyst are then slowly added to the MDI with stirring (-40 rpm). The mixer was then heated to 150°C under nitrogen and mixed to complete the prepolymerization between the MDI and diol. At the end of this period, no increase in torque was measured, meaning that the urethane polymer did not undergo significant chain extension. The polymer was obtained by slowly adding the BDO chain extender to the prepo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com