Graphene electrode and supercapacitor preparation method

A technology of graphene electrodes and supercapacitors, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problem of low specific capacity of supercapacitors, and achieve the effect of improving specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

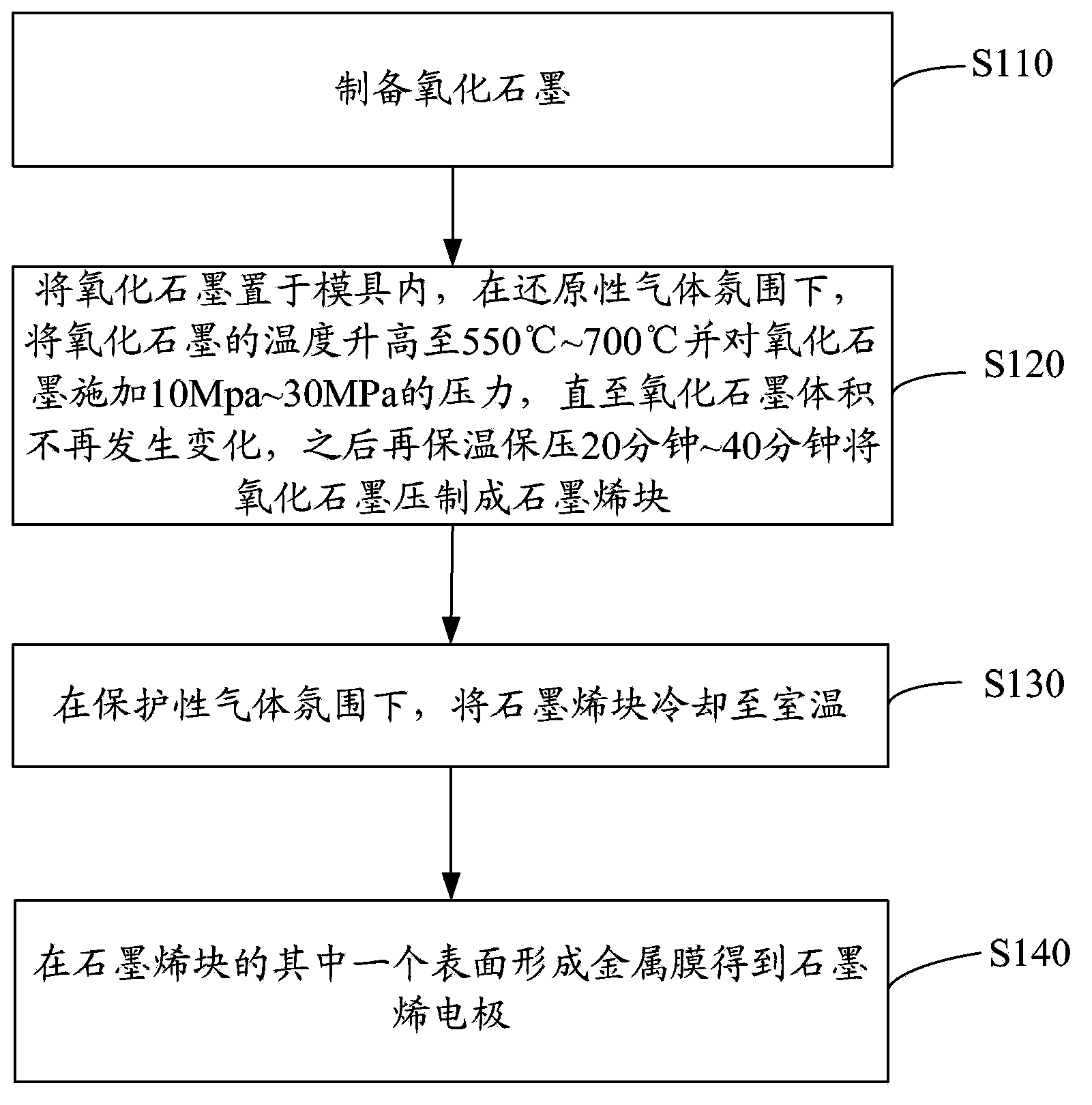

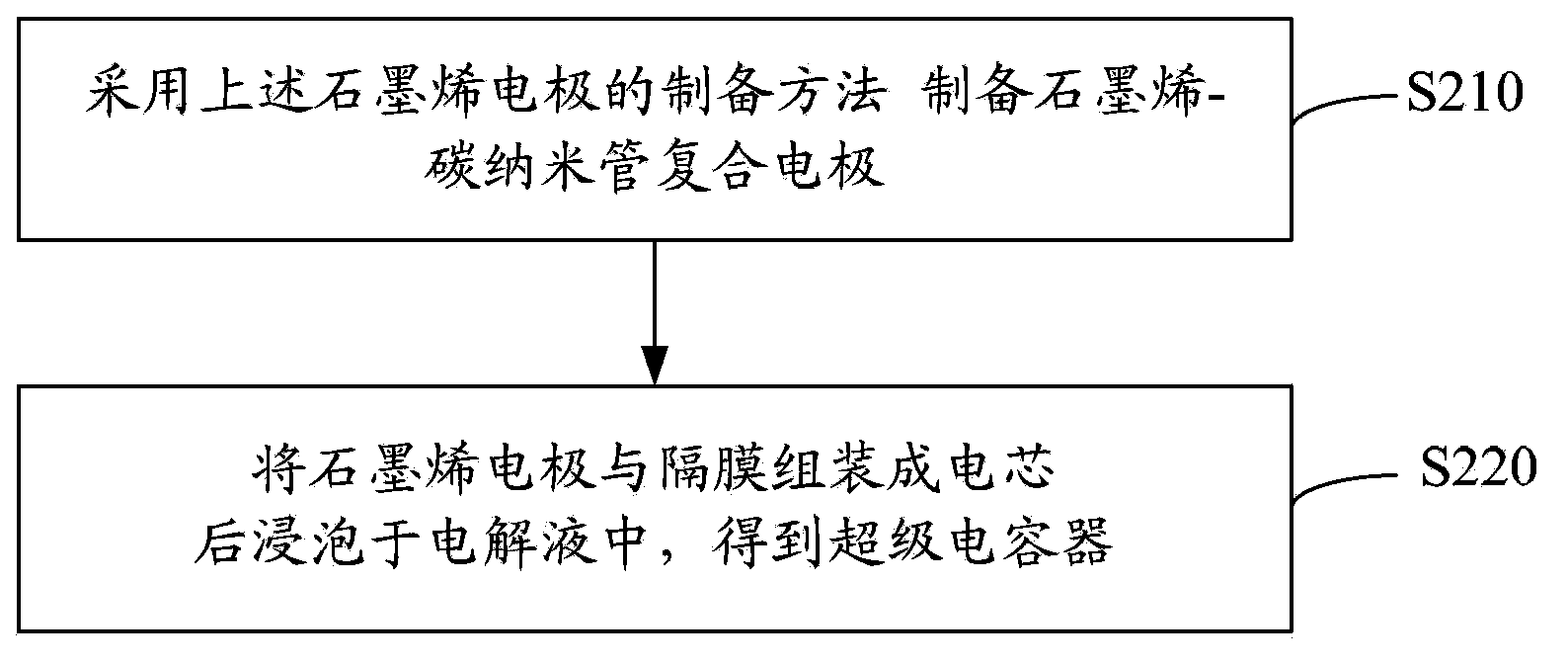

[0026] see figure 1 , the preparation method of the graphene electrode of one embodiment, comprises the steps:

[0027] Step S110, preparing graphite oxide.

[0028] Preparation of graphite oxide comprises the following steps:

[0029] Step 1: adding graphite into concentrated sulfuric acid at 0°C, and then adding potassium permanganate to form a mixed solution, keeping the temperature of the mixed solution below 10°C and stirring for 2 hours.

[0030] Preferably, the purity of graphite is 99.5%.

[0031] Preferably, the solid-to-liquid ratio of graphite to concentrated sulfuric acid is 1g:23mL. The mass concentration of concentrated nitric acid is 30%.

[0032] Preferably, the mass ratio of graphite to potassium permanganate is 1:3.

[0033] Step 2, keeping the temperature of the mixture at room temperature and stirring for 24 hours.

[0034] Step 3. Put the mixed solution in an ice-water mixing bath, add deionized water to the mixed solution, add hydrogen peroxide solu...

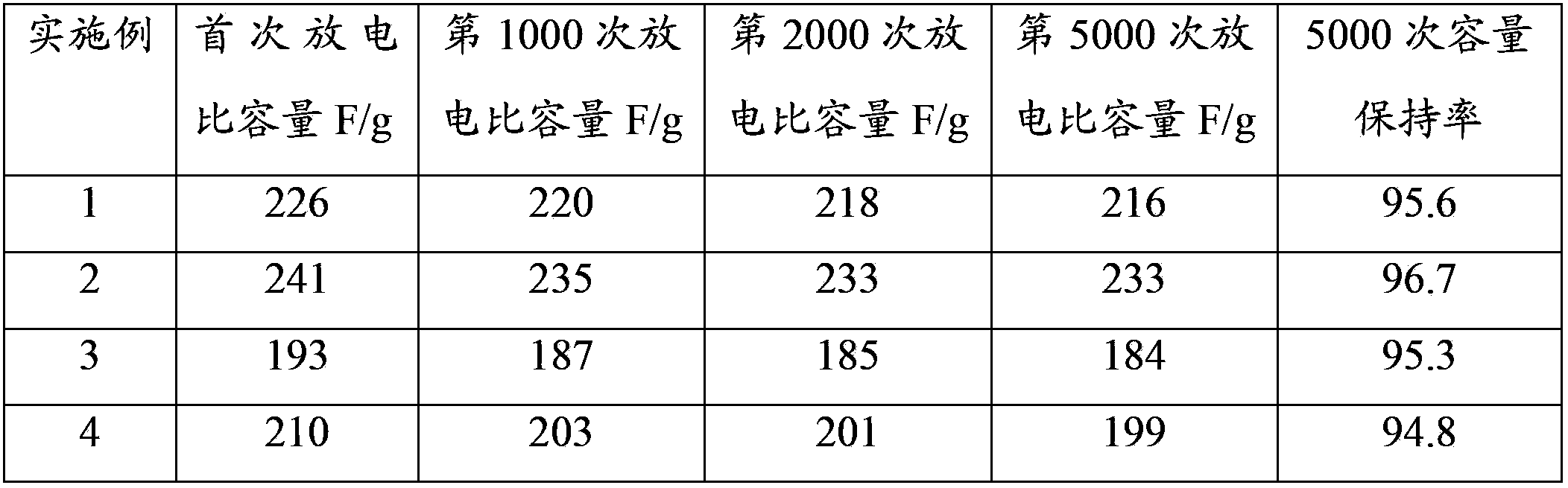

Embodiment 1

[0058] 1. Preparation of graphite oxide by improved Hummers method:

[0059] Add 0.5g of 500-mesh graphite powder to 0°C, 11.5mL of concentrated sulfuric acid, then add 1.5g of potassium permanganate, keep the temperature of the mixture below 10°C, stir for 2h, then stir in a water bath at room temperature for 24h, then place in an ice bath Add 46 mL of deionized water slowly. After 15 minutes, add 140mL of deionized water (which contains 2.5mL of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow, filter with suction, wash with 250ml of hydrochloric acid with a concentration of 10%, and filter with suction until the filtrate Neutral.

[0060] 2. Take 5g of graphite oxide and put it into a 30mm*50mm mold, add a mold cover, transfer the mold to a vertical muffle furnace filled with hydrogen and nitrogen with a volume ratio of 1:1, and apply a constant pressure of 20MPa to the mold , heat the muffle furnace to 550°C until the mold cover no longer mo...

Embodiment 2

[0074] 1. Preparation of graphite oxide by improved Hummers method:

[0075] Add 0.5g of 500-mesh graphite powder to 0°C, 11.5mL of concentrated sulfuric acid, then add 1.5g of potassium permanganate, keep the temperature of the mixture below 10°C, stir for 2h, then stir in a water bath at room temperature for 24h, then place in an ice bath Add 46 mL of deionized water slowly. After 15 minutes, add 140mL of deionized water (which contains 2.5mL of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow, filter with suction, wash with 250ml of hydrochloric acid with a concentration of 10%, and filter with suction until the filtrate Neutral.

[0076] 2. Take 50g of graphite oxide and put it into a 30mm*50mm mold, add a mold cover, transfer the mold to a vertical muffle furnace filled with hydrogen and argon with a volume ratio of 1:5, and apply a constant pressure of 10MPa to the mold Pressure, heat the muffle furnace to 700°C until the mold cover no l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap