PVC synthetic leather surface treating agent, PVC synthetic leather, and preparation methods of PVC synthetic leather surface treating agent and PVC synthetic leather

A surface treatment agent and synthetic leather technology, applied in leather surface treatment, small leather/big leather/leather/fur treatment, fiber treatment, etc., can solve the problem of affecting the appearance of leather, increasing environmental pollution, and uneven leather surface coating and other problems, to achieve the effect of saving the amount of surface treatment agent, saving production cost and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

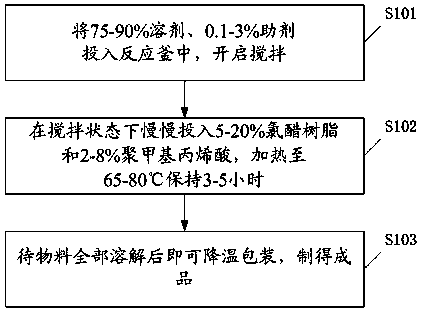

[0040] See figure 1 , The present invention also provides a method for preparing a surface treatment agent for PVC synthetic leather. The surface treatment agent for PVC synthetic leather is a bright surface treatment agent, comprising:

[0041] S101. Put 75-90% solvent and 0.1-3% auxiliary agent into the reaction kettle and start stirring.

[0042] More preferably, put 80-90% solvent and 0.1-1% auxiliary agent into the reactor and turn on the stirring.

[0043] S102. Slowly put in 5-20% vinyl acetate resin and 2-8% polymethacrylic acid while stirring, and heat to 65-80°C for 3-5 hours.

[0044] More preferably, slowly add 10-20% vinyl acetate resin and 2-8% polymethacrylic acid under stirring, and heat to 65-80°C for 4 hours.

[0045] S103. After all the materials are dissolved, the temperature can be lowered and packaged to obtain a finished product.

[0046] Wherein, the auxiliary agent is a modified silicon-based auxiliary agent. Specifically, the auxiliary agent BYK-337 or MHC30-313...

Example Embodiment

[0070] Example 1

[0071] Weigh 45 parts of toluene, 37.8 parts of methyl ethyl ketone, and 0.2 parts of modified silicon additives (BYK-337) in 3 times the amount accurately and put them into the reaction kettle, turn on the stirring, and slowly add the vinyl acetate resin under stirring. 11 3 times the amount of 6 parts of polymethacrylic acid, heated to 80°C for about 4 hours, cooled and packaged to prepare a PVC bright surface treatment agent.

Example Embodiment

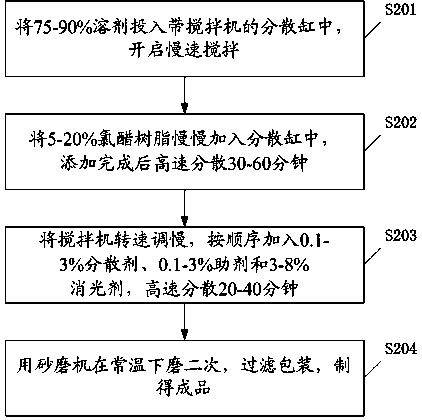

[0072] Example 2

[0073] Put 42 parts of toluene and 38.2 parts of methyl ethyl ketone into the dispersing tank with a mixer in 3 times the amount, turn on the slow stirring, and then slowly add 13 parts of vinyl acetate resin 3 times the amount into the dispersing tank, and disperse at high speed for 40 minutes. Adjust the speed of the mixer to slow down, add 1 part of dispersant MHC10-1140, 0.8 part of auxiliary MHC30-3130, and 5 parts of matting agent in 3 times the amount and in order, disperse at high speed for 30 minutes, and then place it in a sand mill at room temperature. The second time, after the fineness is qualified, filter and package, and prepare PVC matte surface treatment agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap