Displacement level gauge zero point device

A displacer level gauge and positioning adjustment technology, applied in measuring devices, lubricating indicating devices, lubricating parts, etc., can solve the problems of unstable calibration zero value, difficulty in product assembly and production, and difficulty in controlling power, etc. Quality, easy fine-tuning and correction, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

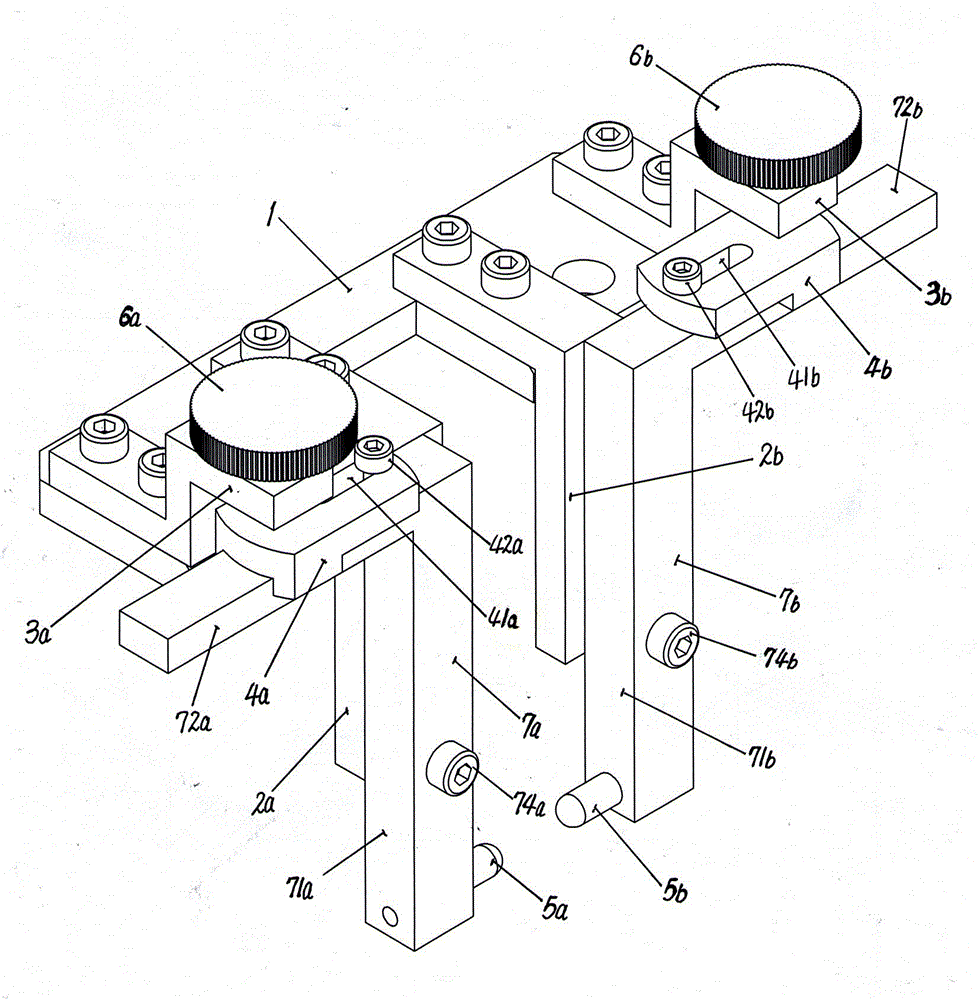

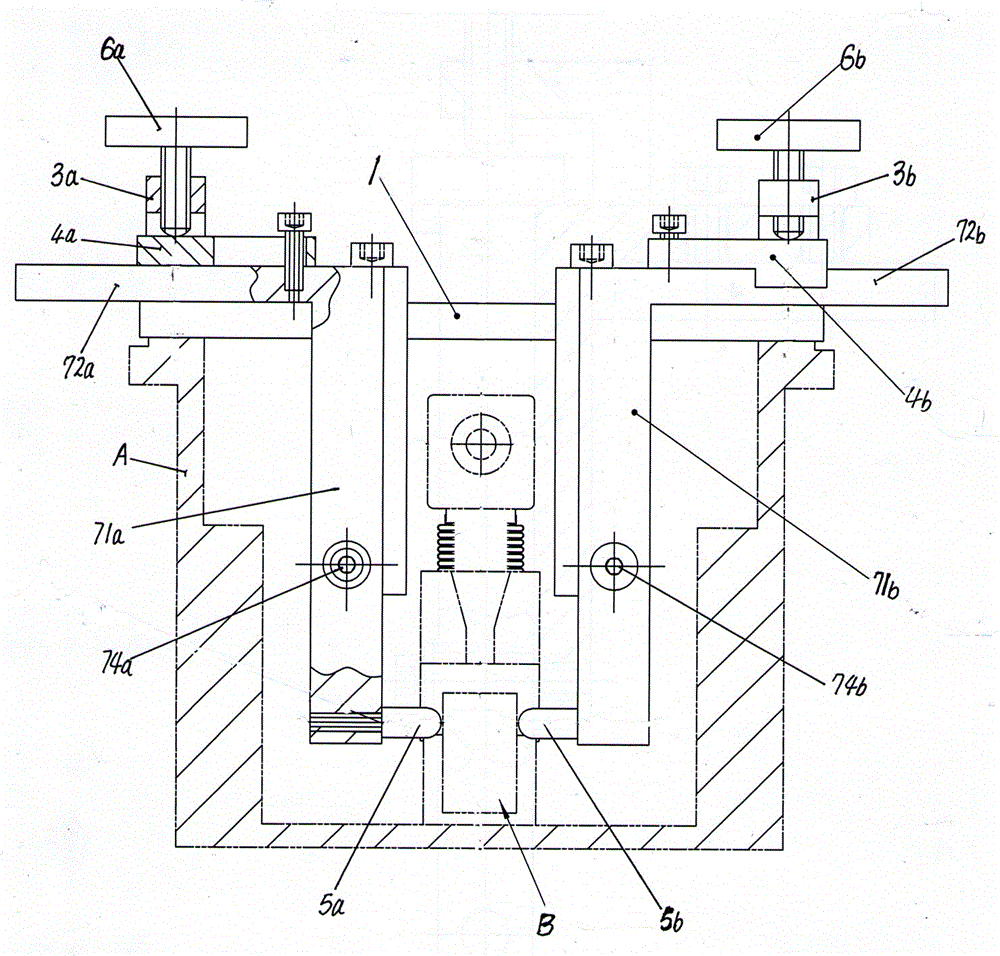

[0010] The present invention is made up of frame plate 1, left and right connecting rods 2a, 2b, left and right adjusting rods 7a, 7b, left and right positioning seats 3a, 3b, left and right positioning adjustment screws 6a, 6b, and left and right connecting rods 2a, 2b are symmetrically passed through the upper ends of the screws respectively. Fixedly connected with the frame plate 1, the left and right positioning seats 3a, 3b are fixedly connected with the upper end surface of the frame plate 1 on the outer sides of the left and right connecting rods 2a, 2b respectively, and the left and right positioning adjustment screws 6a, 6b are respectively installed on the left and right positioning seats 3a, 3b On the screw hole that offers on, left and right adjustment rods 7a, 7b are rectangular rods, and vertical rods 71a, 71b of left and right adjustment rods 7a, 7b are rotatably connected with left and right connecting rods 2a, 2b by screw pin shafts 74a, 74b respectively, The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com