Chambers with clean and dirty parts for manufacturing composite parts

A technology for manufacturing rooms, components, used in aircraft parts, transportation and packaging, airframes, etc., which can solve the problems of disassembly and replacement, which are expensive, time-consuming, and disruptive to production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

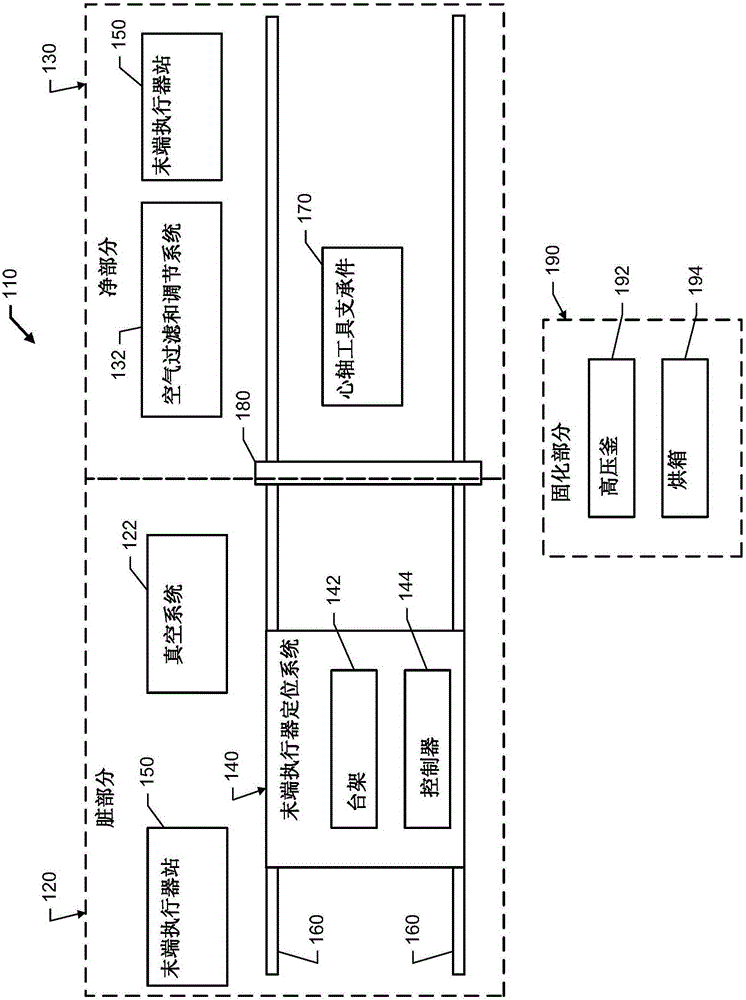

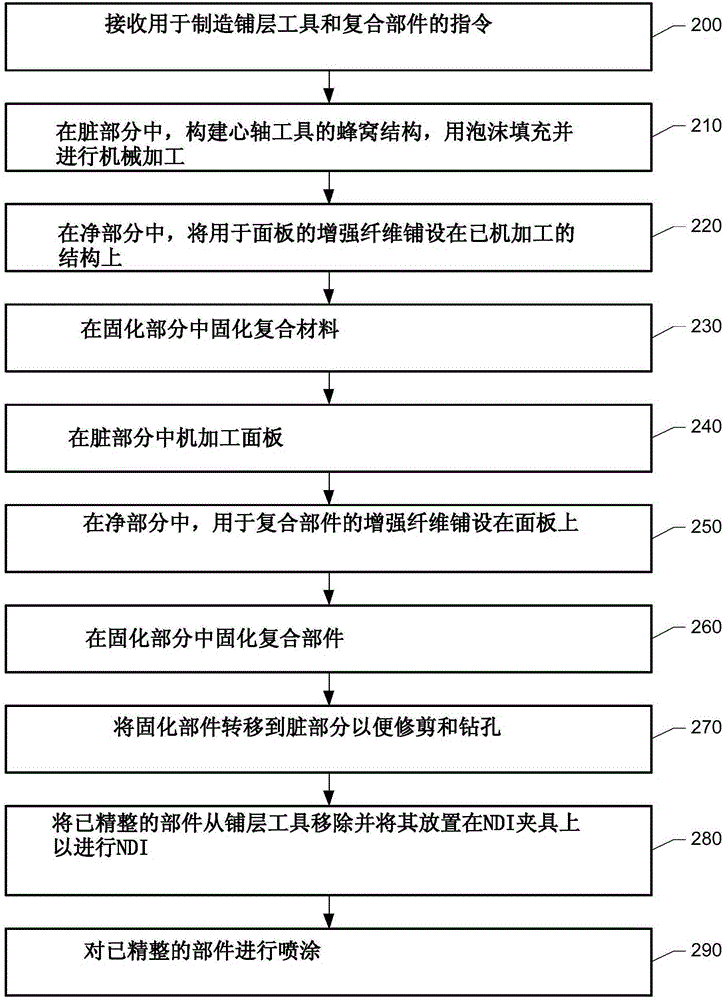

[0016] refer to figure 1 , which shows a manufacturing chamber 110 for manufacturing a composite part comprising layers or plies of reinforcing fibers embedded in a matrix. An example of a composite is carbon fiber reinforced plastic (CFRP), where the components can include carbon fibers embedded in an epoxy resin matrix.

[0017] Fabrication chamber 110 includes a dirty section 120 and a clean section 130 . Operations in dirty portion 120 include, but are not limited to, assembly and machining (eg, trimming, milling, and drilling). Operations are considered dirty if they create dust or contamination that violates cleanroom requirements for handling uncured composites. For "dirty" operations, such as machining, the dirty section 120 may include a vacuum system 122 to minimize dust and debris to facilitate cleanup. The vacuum system 122 may have a dust removal efficiency as high as 98% or greater.

[0018] Operations in the clean section 130 include composite layup on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com