Large-area aluminum substrate collecting device

A collection device, aluminum substrate technology, applied in transportation and packaging, stacking of objects, etc., can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

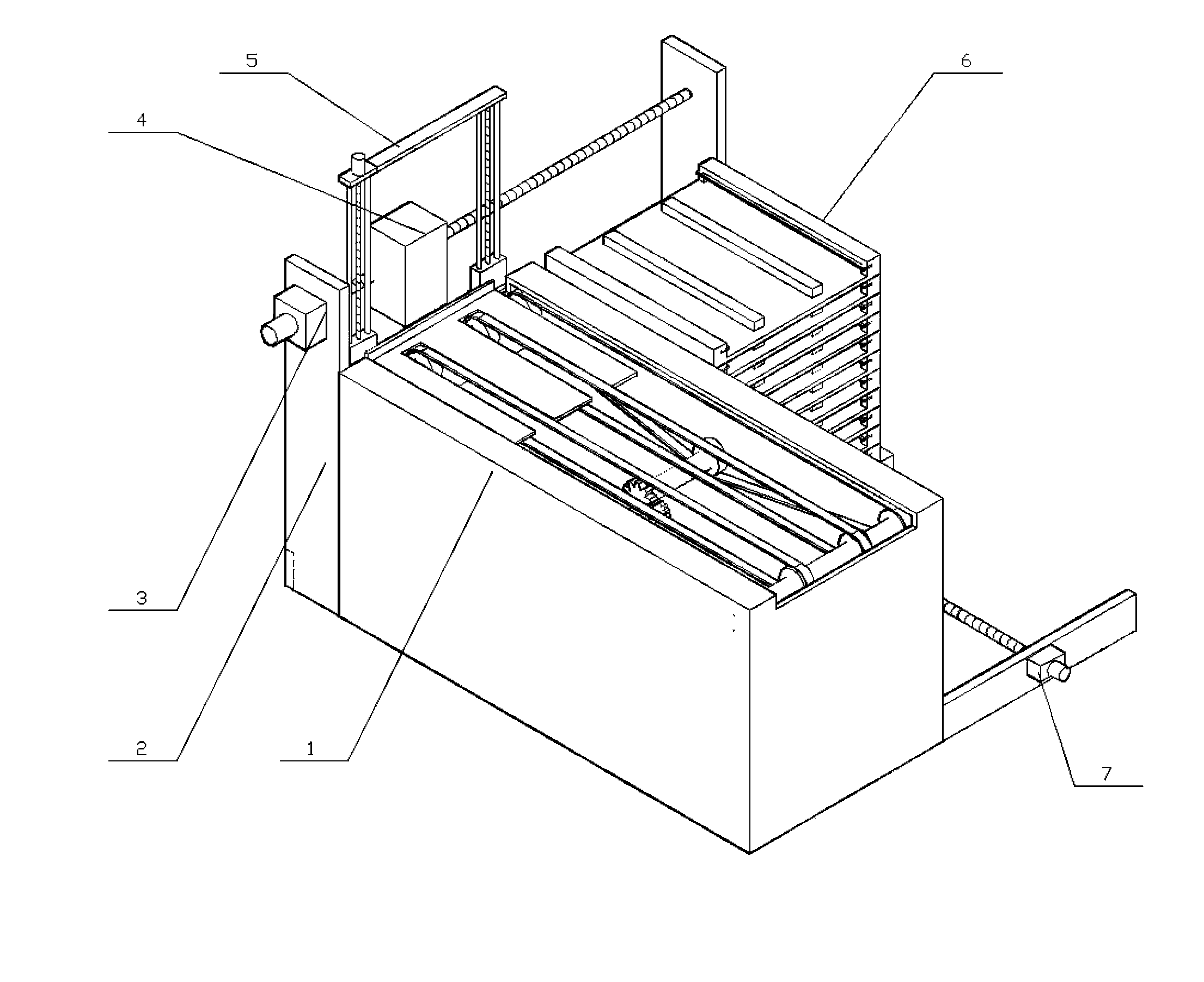

[0014] The accompanying drawing shows the structure of an embodiment of the present invention, as shown in the figure, the present invention collects large aluminum substrates, especially aluminum substrates with a size of 1m×1m; The barge 1 is installed at the exit of the aluminum substrate tunnel furnace, and a belt pulley transmission mechanism is installed on the barge 1, and a large aluminum substrate is placed on the belt;

[0015] The connecting platform 1 is provided with a screw nut lifting mechanism 5 near the exit, and the screw nut lifting mechanism 5 includes a carrier platform, which goes deep into the connecting platform 1 and is located below the belt; The length of the leading screw in the nut lifting mechanism is greater than the height of the collecting frame 6;

[0016] A moving nut block 4 is installed on the back side of the above-mentioned leading screw nut lifting mechanism 5, and an internally threaded hole is provided inside the moving nut block 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com