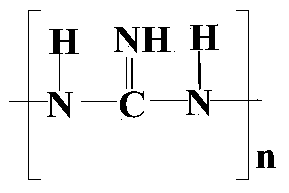

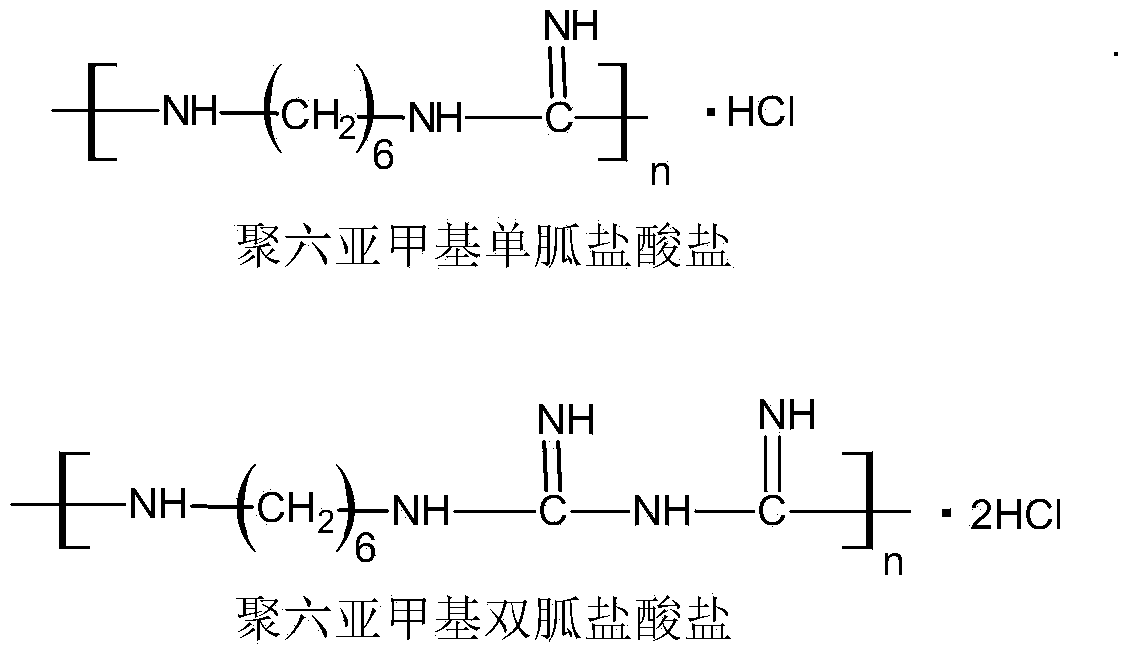

Preparation method of permanently-antibacterial poly guanidine alginate fibers

A technology of seaweed fiber and polyguanidine, which is applied in the direction of fiber chemical characteristics, rayon manufacturing, alginate artificial filament, etc., can solve the problems of poor durability, inability to reuse, not resistant to washing, etc., and achieve good compatibility , Good environmental friendliness, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Synthesize polyguanidine mother liquor, control its polymerization degree n to be 15, contain polyguanidine 35Kg, when the temperature of the stock solution drops from 160°C to 80°C, add 650Kg of 10% sodium alginate solution dropwise under stirring, and react at a constant temperature of 45°C 60min.

[0038] (2) Following the step (1), add 0.077Kg of 3% mixed rare earth chloride dropwise, and react at a constant temperature of 30°C for 45min to obtain the spinning mother liquor.

[0039] (3) According to the existing wet spinning process: spinning, coagulation (adding 1.5% mixed rare earth chloride to the calcium chloride coagulation bath), stretching, the permanent antibacterial polyguanidine seaweed fiber can be obtained.

[0040] The antibacterial rate of the fiber to Staphylococcus aureus and Escherichia coli is 99.9%. After washing 100 times, the antibacterial rate still reaches 99%.

Embodiment 2

[0042] (1) Synthesize polyguanidine mother liquor, control its degree of polymerization n to 21, and contain polyguanidine 0.1Kg. When the temperature of the stock solution drops from 168°C to 60°C, gradually add 999Kg of 10% sodium alginate solution under stirring, and keep the temperature at 55°C React for 90 minutes.

[0043] (2) Following step (1), add 1.5 kg of 3% mixed rare earth nitrate dropwise, and react at a constant temperature of 32°C for 45 minutes to obtain the spinning mother liquor.

[0044] (3) According to the existing wet spinning process: spinning, coagulation (1.5% mixed rare earth chloride is added to the calcium chloride coagulation bath), stretching, and the permanent antibacterial polyguanidine seaweed fiber is obtained.

[0045] The antibacterial rate of the fiber to Staphylococcus aureus and Escherichia coli is 90%. After washing 100 times, the antibacterial rate still reaches 85%.

Embodiment 3

[0047] (1) Prepare 200Kg of 0.5% sodium alginate solution, add dropwise 0.44Kg of 25% polyguanidine solution with a degree of polymerization n of 17 under stirring, raise the temperature to 45°C, and react at constant temperature for 60min.

[0048] (2) Following step (1), add 0.37Kg of 3% mixed rare earth nitrate dropwise, and react at a constant temperature of 25°C for 45min to obtain the spinning mother liquor.

[0049] (3) According to the existing wet spinning process: spinning, coagulation (1.5% mixed rare earth chloride is added to the calcium chloride coagulation bath), stretching, and the permanent antibacterial polyguanidine seaweed fiber is obtained.

[0050] The antibacterial rate of the fiber to Staphylococcus aureus and Escherichia coli is 99%. After washing 100 times, the antibacterial rate still reaches 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com