Transparent printed circuit board and manufacturing method thereof

A technology for printed circuit boards and production methods, which is applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of reducing the transparency of transparent circuit boards, and achieve the effect of enhanced transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The transparent printed circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

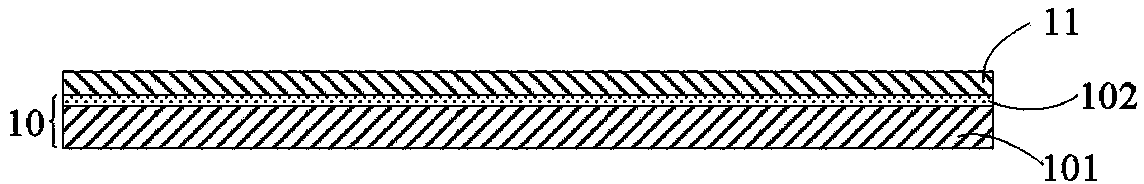

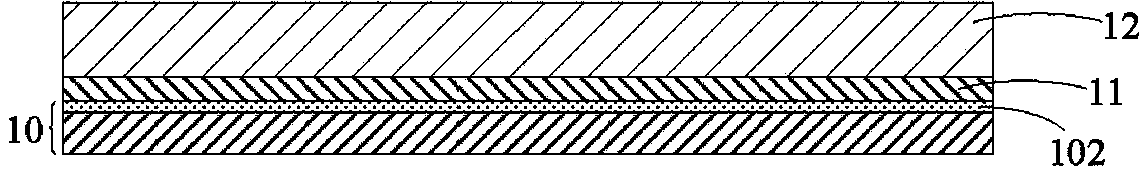

[0018] see Figure 1 to Figure 6 The manufacturing method of the transparent printed circuit board provided by the embodiment of the technical solution comprises the following steps:

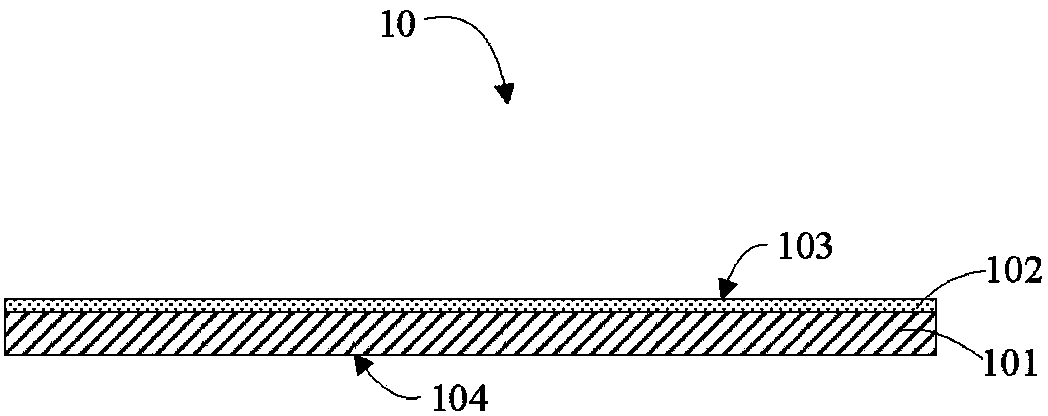

[0019] Step 1: See figure 1 , providing a single-sided blackened copper foil 10, the single-sided blackened copper foil 10 includes a copper body layer 101 and a first blackened layer 102, and the single-sided blackened copper foil 10 has an opposite first surface 103 and a second surface 104 , the first blackened layer 102 is formed on one side of the copper body layer 101 , and the surface of the first blackened layer 102 constitutes the first surface 103 of the single-sided blackened copper foil 10 . The first blackened layer 102 is formed after blackening treatment is performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap