Cleaning apparatus

A cleaning device and cleaning surface technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unremovable pollutants, unremovable pollutants, and adverse effects on wafer quality, so as to suppress adverse effects and reduce Effect of Backside Contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

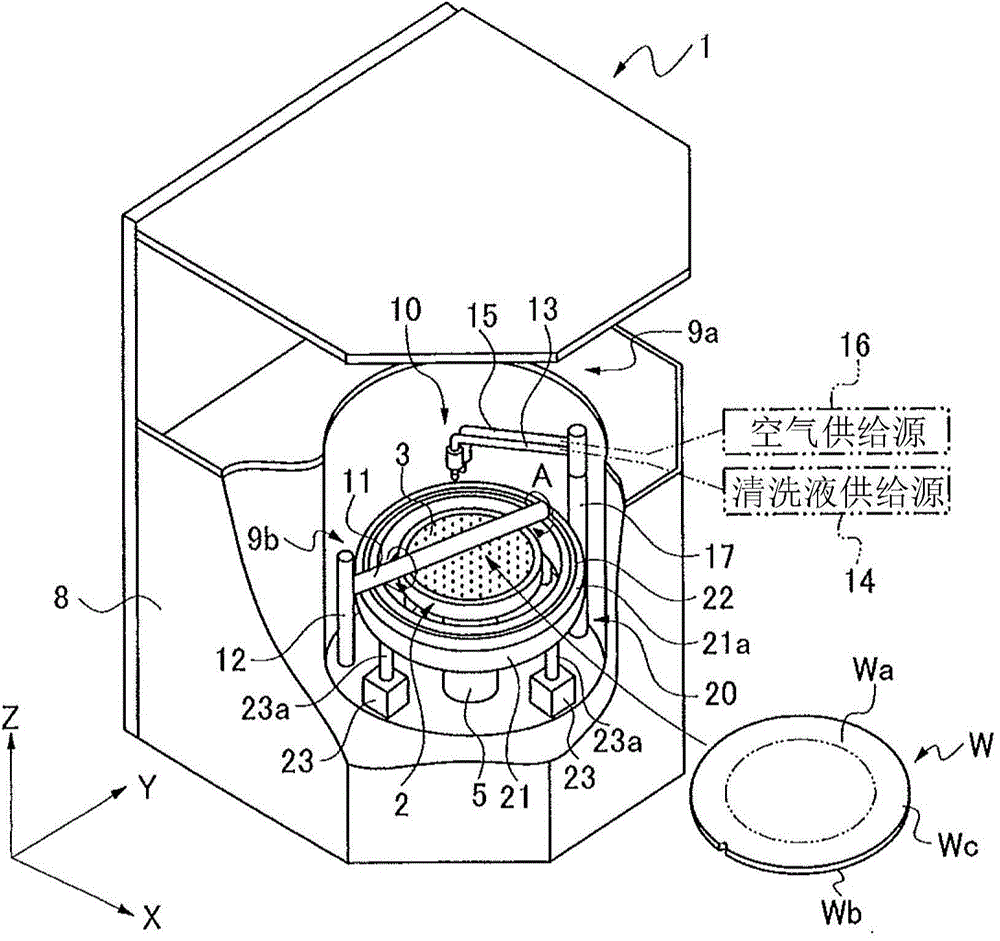

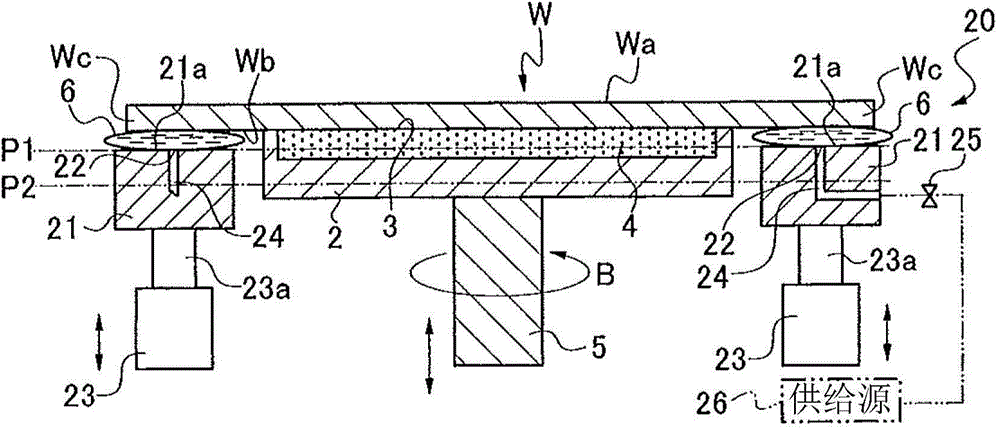

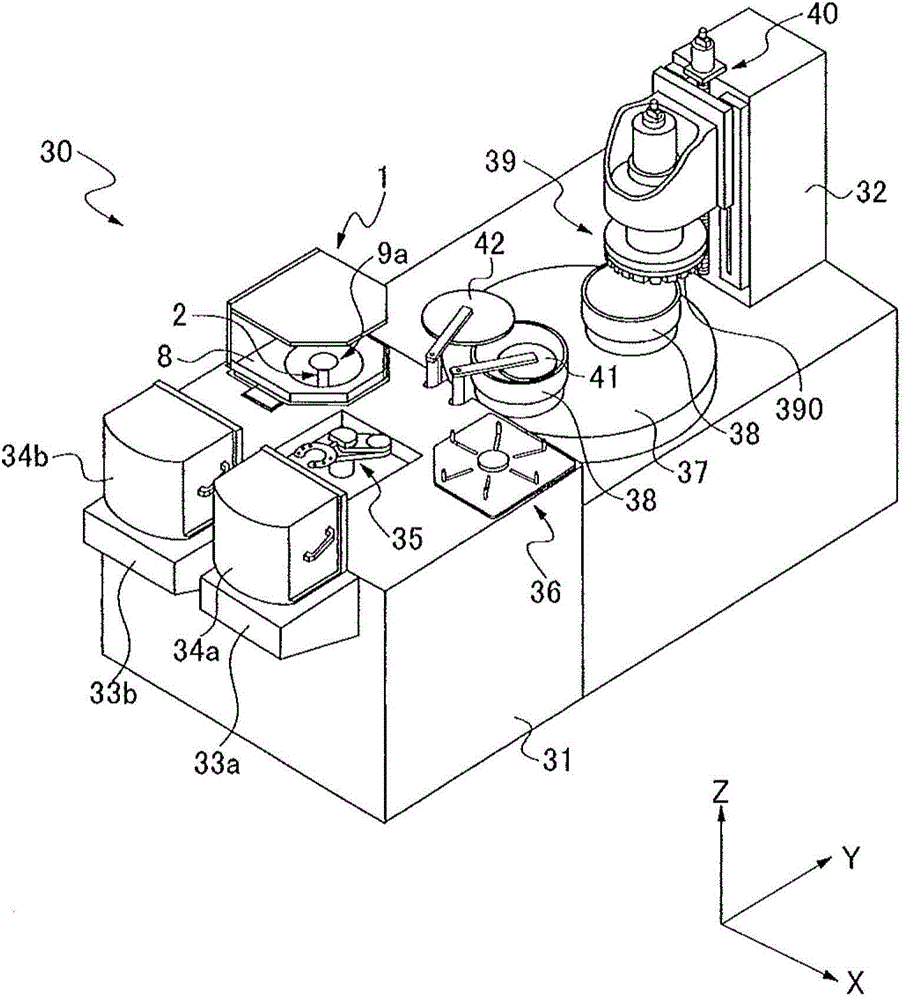

[0037] while referring to figure 1 as well as figure 2 The structure of the cleaning apparatus 1 for cleaning the wafer W which is the workpiece will be described. The cleaning device 1 has: a rotary table 2 for holding a workpiece and capable of high-speed rotation; a cleaning member 10 for cleaning the workpiece; and a peripheral holding member 20 formed to surround the rotary table 2 and support The outer peripheral portion of the workpiece, and the cleaning device 1 is configured to be accommodated in a space formed in the central portion of the container 8 .

[0038] Such as figure 1 as well as figure 2 As shown, the rotary table 2 is formed to have a diameter smaller than the outer diameter of the workpiece. The rotary table 2 has a porous member 4, and the surface side of the rotary table 2 is an upper surface 3 for suction holding a workpiece. The lower end of the rotary table 2 is connected to a rotary shaft 5 that rotates the rotary table 2 at high speed. In ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap