Protection method for inner circuit of printed circuit board

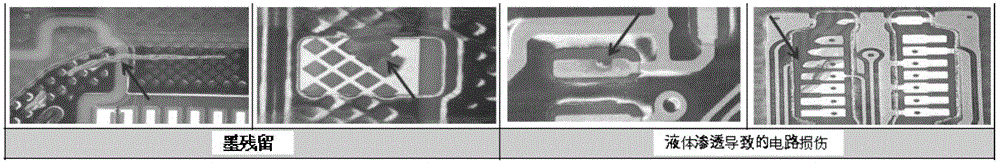

A technology for printed circuit boards and inner-layer circuits, applied in the directions of printed circuits, printed circuit manufacturing, and manufacturing of printed circuit precursors, etc., can solve the problems of longer process time, residual strippable ink, and increased material loss, so as to reduce defects. , The effect of increasing adhesion and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Next, the inner layer circuit protection process of the printed circuit board of the present invention will be described in detail with reference to the accompanying drawings. The same structures or components in the drawings use the same reference signs as far as possible. In addition, the disclosed structures and functions that may confuse the focus of the present invention will not be repeated here.

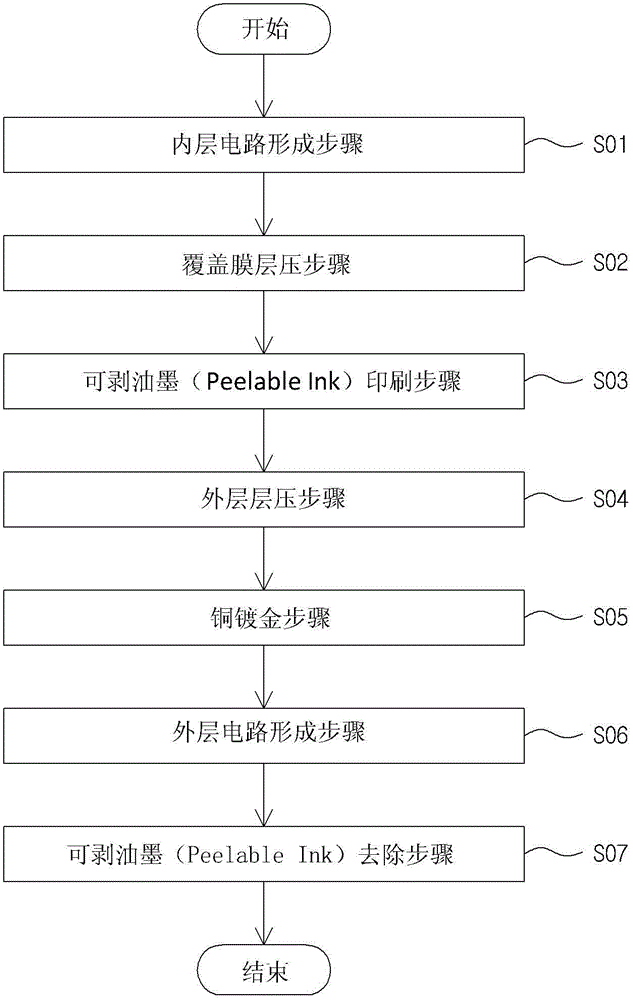

[0031] Figure 4 It is a schematic process diagram of the inner layer circuit protection process of the printed circuit board according to an embodiment of the present invention.

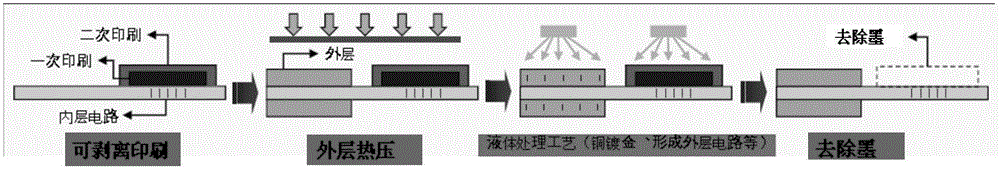

[0032] like Figure 4 As shown, the inner layer circuit protection process of the printed circuit board of the present invention is characterized in that, comprising: the inner layer circuit forming step S10, etching and removing the inner layer surface made of copper (Cu) to form the inner layer circuit; Pressing step S20, laminating and processing the upper part of the inner layer throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap