Method for removing water-soluble pesticide residues in catechin preparation process

A pesticide residue and preparation technology, applied in the direction of organic chemistry, can solve problems such as hidden dangers to human health and safety, obstruction of export trade, market application restrictions, etc., to reduce the base of water-soluble pesticide residues, facilitate equipment, and solve the problems of excessive pesticide residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

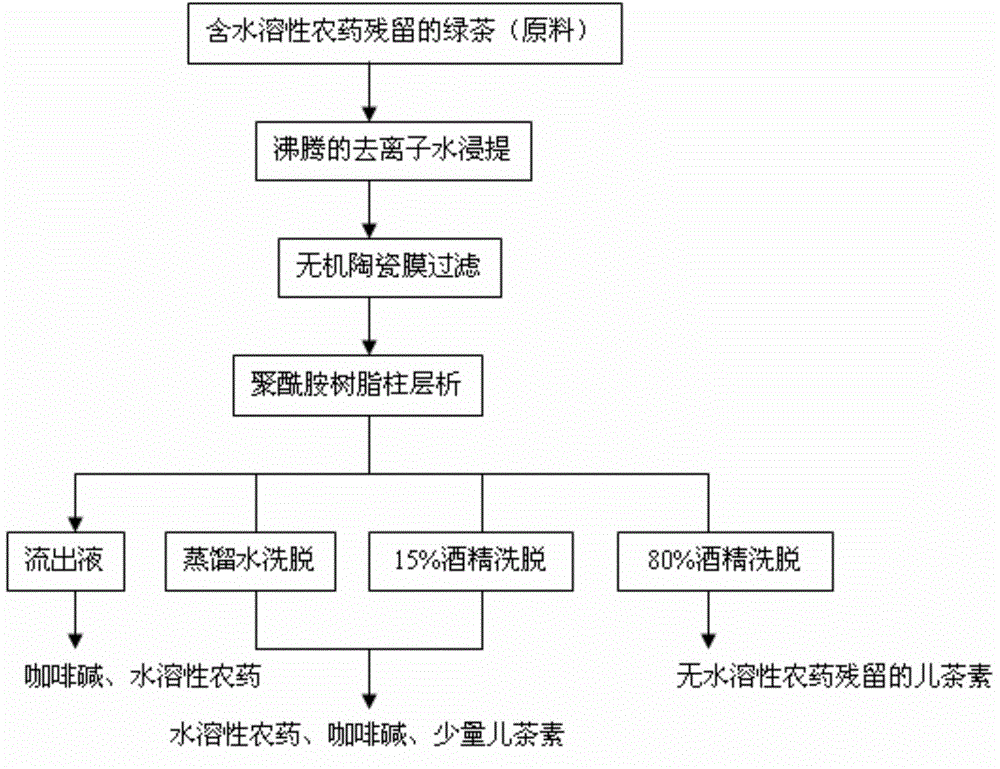

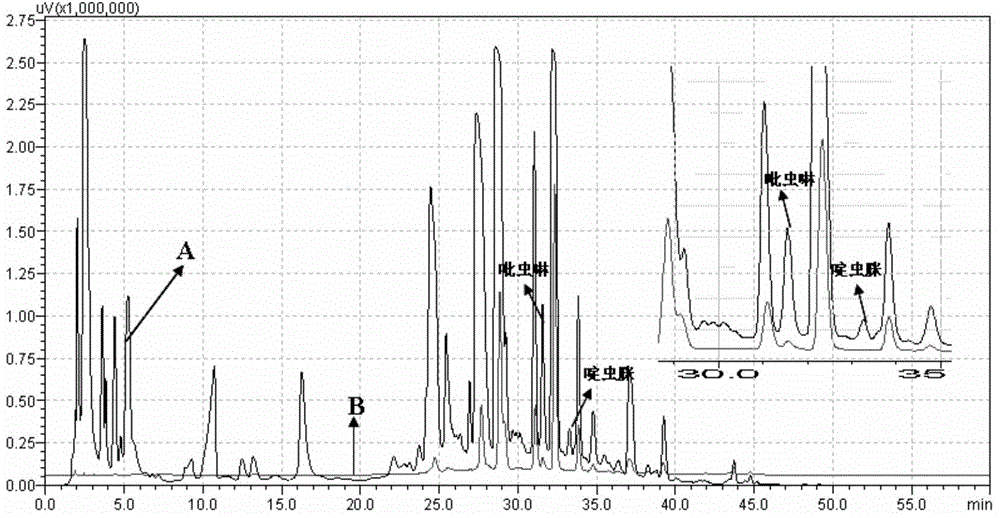

[0028] according to figure 1 As shown in the process flow chart, the green tea raw materials that have been tested to contain imidacloprid and acetamiprid water-soluble pesticides are crushed, weighed 2 kg and added to 30 L of boiled deionized water, keep boiling slightly for 10 minutes, pour out the tea soup, and repeatedly extract the tea dregs once. Merge the two tea soups, cool to 20-25°C, pre-filter to obtain 50L of primary filtrate, and then filter through a ceramic membrane with a pore size of 0.2μm (microfiltration), operating temperature is 40°C, pressure is 0.3MPa, and 40L fine filtrate is obtained , concentrated by reverse osmosis membrane to a solid content of 5-6%, to obtain tea extract.

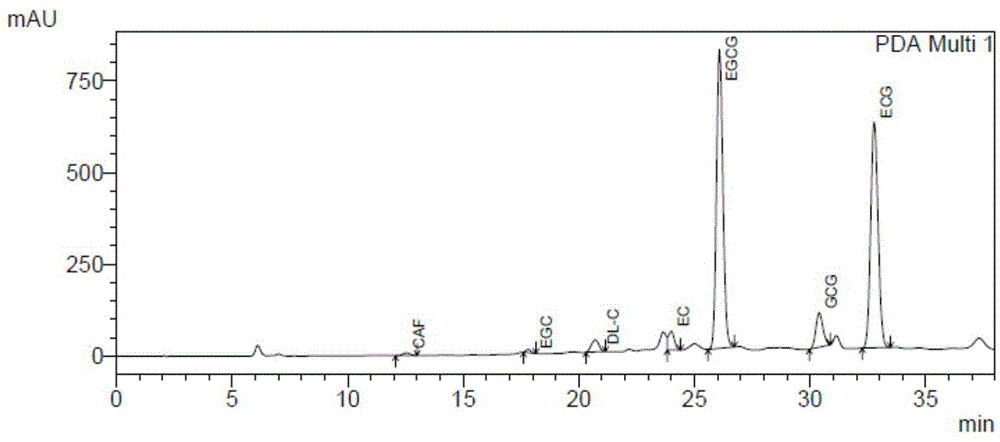

[0029] Take the above tea extract, pass it through a polyamide chromatography column (Ф4cm×80cm, polyamide filling height is 40cm) at a flow rate of 2mL / min, discard the effluent; first elute with 2000mL deionized water (flow rate 1.5mL / min) , then elute with 1500mL of 15% alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com