Thermal insulation reflection coating polymer composite packing

A composite filler, heat insulation reflection technology, applied in the field of coatings, to achieve the effects of improving infrared light reflectivity, improving film-forming performance, and good heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

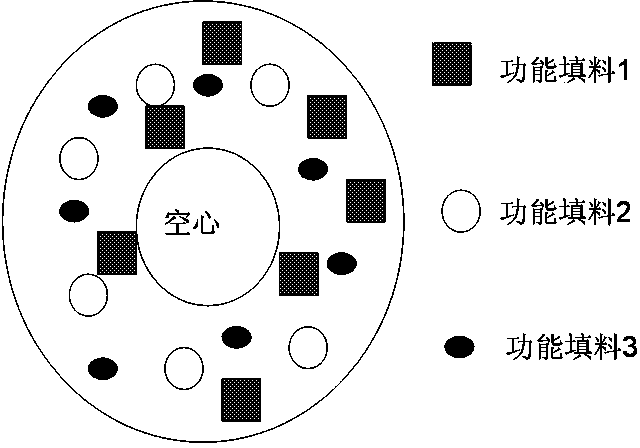

[0021] Weigh 50g polystyrene as resin, add 20g titanium dioxide (functional filler 1), 20g hollow glass microspheres (functional filler 2) and 10g aluminum oxide (functional filler 3) of infrared reflective powder respectively, and mix them by physical method Finally, obtain a uniform and stable polymer composite solution, and then adopt the polymer hollow microsphere preparation method to prepare polystyrene / titanium dioxide-hollow glass microspheres-polymer hollow composite microspheres of aluminum oxide, and its structure is shown as figure 1 shown. Add the prepared polystyrene / titanium dioxide-hollow glass microspheres-aluminum oxide solid content of polymer composite microspheres with a weight ratio of 20%, and water-based polyacrylic acid emulsion and other coating additives (such as defoamers, Leveling agent, surface active agent) Stir evenly to configure white heat-insulating reflective coating, according to the GB / T25261-2010 test standard for reflective heat-insulat...

Embodiment 2

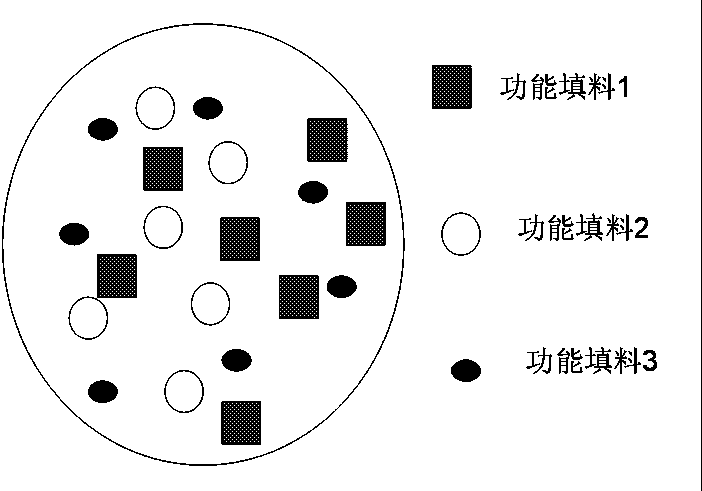

[0023] Using 70g polystyrene as resin, add 10g titanium dioxide (functional filler 1), 10g hollow glass microspheres (functional filler 2) and 10g aluminum oxide (functional filler 3) of infrared reflective powder respectively, and mix them by physical method Obtain a uniform and stable polymer composite solution, and then use the preparation method of polymer solid microbeads to prepare polystyrene / titanium dioxide-hollow glass microspheres-alumina composite functional fillers, and its structure is shown as figure 2 shown. Then add the polymer composite microsphere solid content that the prepared weight ratio is 30% polystyrene / titanium dioxide-hollow glass microspheres-aluminum oxide, and water-based polyacrylic acid emulsion and other coating additives (such as defoamer , leveling agent, surfactant) and mix evenly to configure yellow heat-insulating reflective coatings. According to the GB / T25261-2010 test standard for reflective heat-insulating coatings for buildings, the...

Embodiment 3

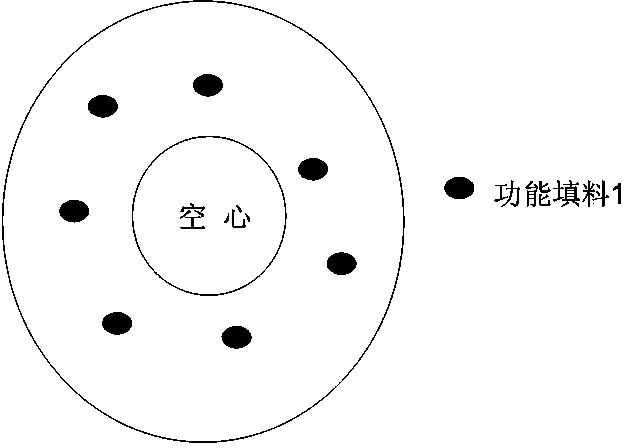

[0025] Using 80g polystyrene as resin, add 20g titanium dioxide (functional filler 1) of infrared reflective powder; use physical method to mix the solution to obtain a uniform and stable polymer composite solution, and then use the preparation method of polymer hollow microbeads to prepare polystyrene / titanium dioxide composite functional filler, its structure is shown as image 3 shown. Then add the prepared polystyrene / titanium dioxide polymer composite microspheres with a weight ratio of 30% solid content, stir well with water-based polyacrylic acid emulsion and other coating additives (such as defoamers, leveling agents, surfactants) Equipped with red heat-insulating reflective paint, tested according to GB / T25261-2010 building reflective heat-insulating paint testing standard, its solar reflectance is 0.85, which is higher than the 0.80 required by the national standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com