Assembling system

An assembly system and assembly area technology, applied in the field of assembly line, can solve problems such as low assembly efficiency of electrical equipment, achieve the effects of convenient and fast transportation, improve work efficiency, and save human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

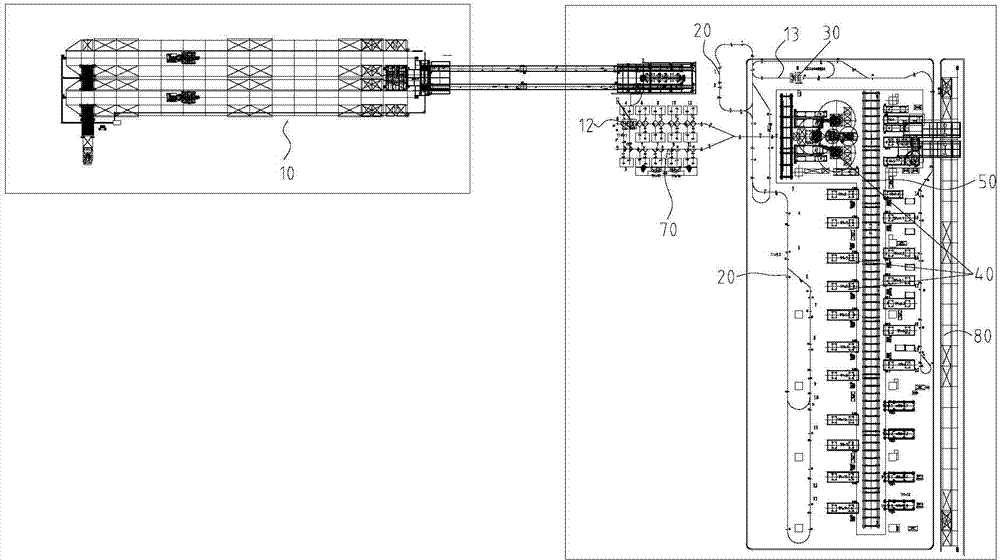

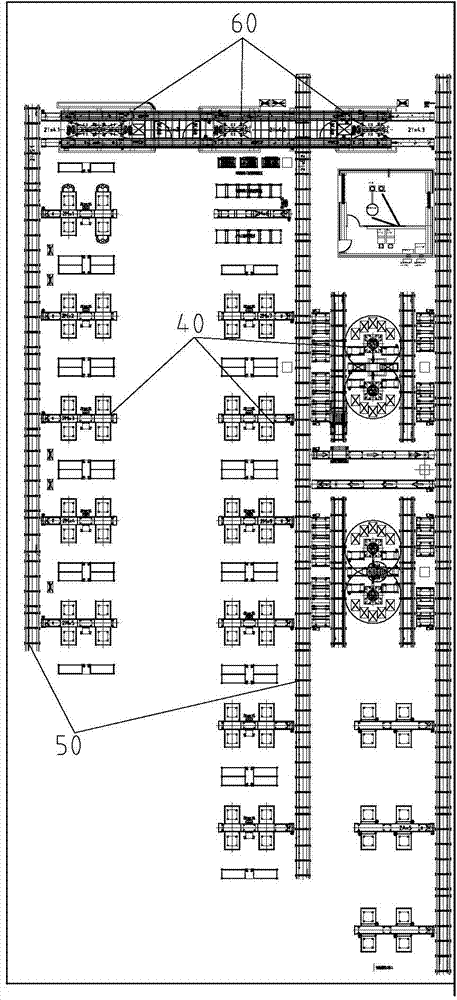

[0021] Such as figure 1 As shown, the assembly system of this embodiment includes: a first material warehouse 10, an assembly area, a first track 20, an unmanned transport vehicle 30, and a first reclaiming device. Wherein, an assembly device 40 is provided in the assembly area, the first track 20 is arranged between the first material storage 10 and the assembly device 40, and the unmanned transport vehicle 30 is movably arranged on the first track 20. The materials stored in the first material storage 10 are moved to the first track 20 through the first reclaiming device, so that the unmanned transport vehicle 30 and the first reclaiming device cooperate with each other to move the mater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap