Soldered joint nickel alloy sea water desalting plant

A nickel alloy and welding head technology, which is applied in the field of welding head nickel alloy seawater desalination devices, achieves the effects of good wear resistance, strong corrosion resistance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

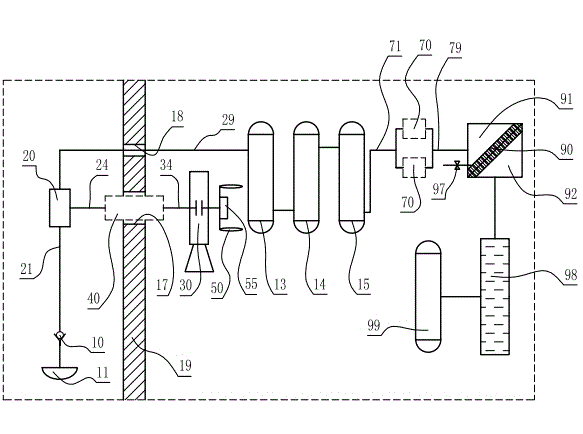

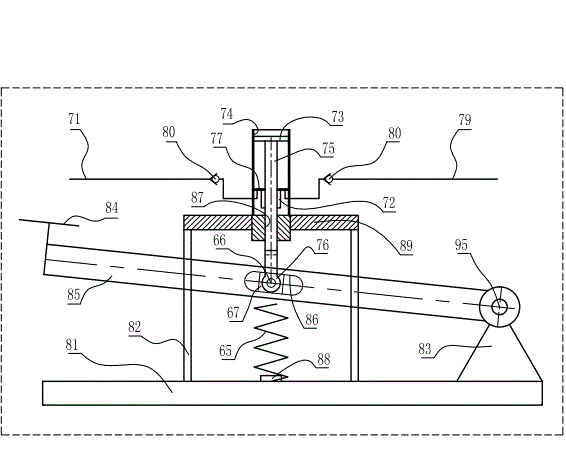

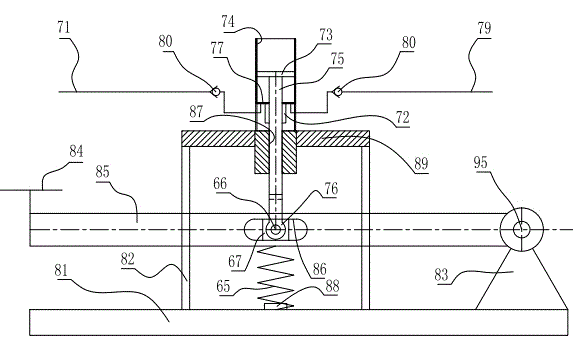

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] figure 1 , figure 2 , Figure 5 with Figure 11 Among them, a welding head nickel alloy seawater desalination device, the hand-operated entertainment device 55 located in the room drives the high-speed output shaft 34 of the gear speed increaser box 30, and the high-speed output shaft 34 and the coupling input of the nickel alloy welding head coupling 40 The welding groove 341 is welded and fixed, and the nickel alloy welding head coupling 40 passes through the transmission pipe isolation hole 17 of the separation wall 19 from the inside to the outside, and the coupling output welding slope of the nickel alloy welding head coupling 40 The mouth 241 is welded and fixed to the lift pump input shaft 24 of the centrifugal lift pump 20, and the lift inlet pipe 21 of the centrifugal lift pump 20 is connected to the seabed wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com