A kind of steel strip continuous copper plating method

A continuous copper-plating and copper-plating technology for steel strips, applied in the field of alkaline copper plating, can solve the problems of reduced production efficiency, small bright range, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

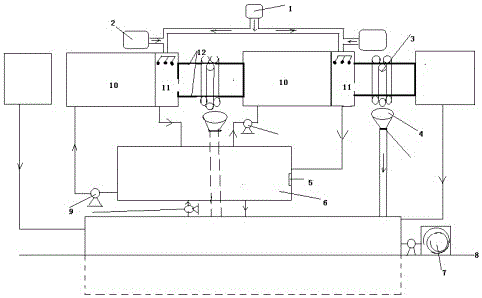

Image

Examples

Embodiment 1

[0015] The structure of the three female tanks is composed of a copper plating tank, a female tank, a filter pump, an empty tank, an airtight treatment tank, and a refrigerator. Specifically, there are six copper plating tanks, each of which is a group of two, and the airtight treatment tank is equipped with a freezer machine; a sodium carbonate concentration sensor is provided in the mother tank, the volume of the mother tank is about twice the volume of the electroplating copper tank, and the volume of the airtight treatment tank is about twice the volume of the mother tank; the power of the pump is the same, the pump (filter Machine) The volume of the plating solution conveyed (filtered) per hour is about 10 times the volume of the copper plating tank (mother tank); there is a vacancy tank about 100mm long at the exit end of the steel strip continuously copper-plated, and at the exit of the steel strip There are three high-pressure nozzles arranged at a 45° angle from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com