Supported PVC (polyvinyl chloride) heat stabilizer and preparation method thereof

A heat stabilizer, load-type technology, applied in the field of load-type PVC heat stabilizer and its preparation, can solve the problems of low alkali capacity, restriction of application range, decline, etc., achieve easy source, increase heat stability effect, and prepare easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Stir and disperse activated clay with activity degree of 230, decolorization rate of 98, and particle size of 400 mesh in 12.5 times water for 0.5 hour to obtain activated clay suspension; disperse calcium hydroxide accounting for 67% of activated clay mass in 3 times 30°C Put it in water for 8 hours to obtain a calcium hydroxide emulsion; raise the temperature of the activated clay suspension to 75°C, add the calcium hydroxide emulsion evenly within 3 hours for loading, continue stirring for 1 hour after the addition, and then add 6.5% of the mass of activated clay stearic acid, stirred and reacted for 60 minutes; filtered, dried and pulverized to obtain a loaded PVC heat stabilizer.

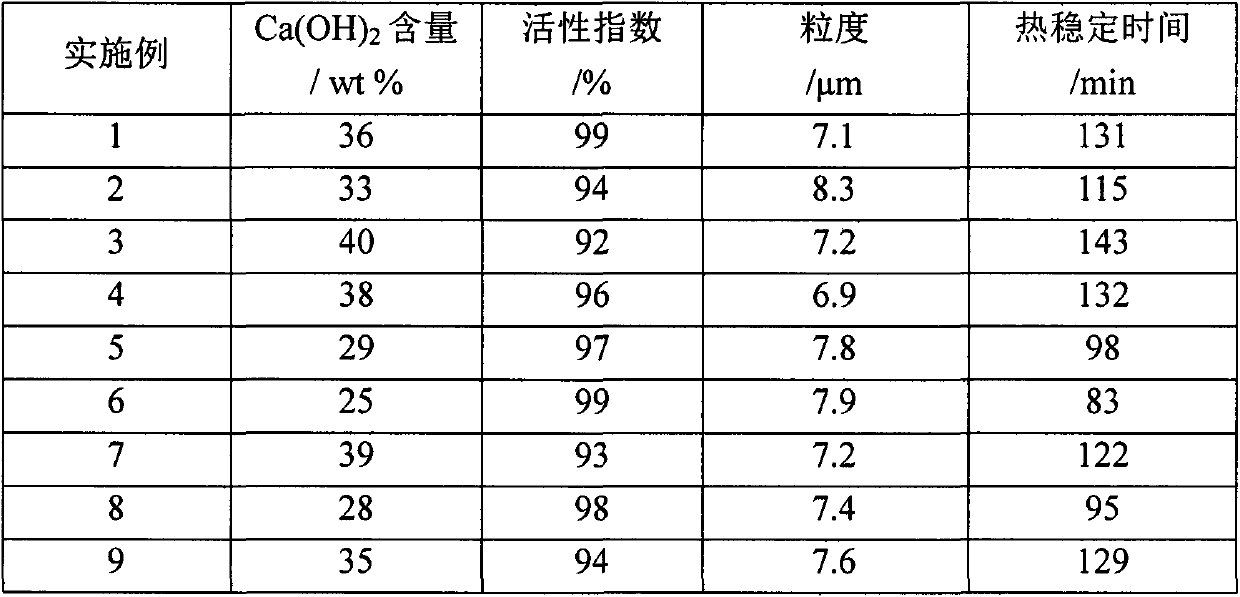

[0023] The Ca(OH) of the loaded PVC heat stabilizer particles 2 The analysis results of content, activity index, particle size and thermal stability time are shown in Table 1.

Embodiment 2

[0025] The activated clay with activity degree of 230, decolorization rate of 98 and particle size of 400 mesh was stirred and dispersed in 12 times of water for 1 hour to obtain activated clay suspension; put 60% calcium hydroxide into calcium hydroxide mass 5 times of the water at 40°C, put it in water for 10 hours to obtain a calcium hydroxide emulsion; raise the temperature of the active clay suspension to 75°C, add the calcium hydroxide emulsion evenly within 3 hours for loading, continue stirring for 1 hour after the addition, and then Stearic acid with 4% mass of activated clay was added, stirred and reacted for 60 minutes; filtered, dried and pulverized to obtain a load-type PVC heat stabilizer.

[0026] The Ca(OH) of the loaded PVC heat stabilizer particles 2 The analysis results of content, activity index, particle size and thermal stability time are shown in Table 1.

Embodiment 3

[0028] The activated clay with activity degree of 230, decolorization rate of 98 and particle size of 700 mesh was stirred and dispersed in 15 times of water for 0.5 hour to obtain activated clay suspension; put 70% calcium hydroxide into calcium hydroxide mass 3 times the water of 50°C, put it in water for 10 hours to obtain a calcium hydroxide emulsion; raise the temperature of the activated clay suspension to 75°C, add the calcium hydroxide emulsion evenly within 3 hours for loading, continue stirring for 1 hour after the addition, and then Stearic acid with 4% mass of activated clay was added, stirred and reacted for 50 minutes; filtered, dried and pulverized to obtain a load-type PVC heat stabilizer.

[0029] The Ca(OH) of the loaded PVC heat stabilizer particles 2 The analysis results of content, activity index, particle size and thermal stability time are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com