Measuring method and wireless measuring device for three-axis coordinates of base point in rock mass drilling

A three-dimensional coordinate, wireless measurement technology, applied in the field of rock mass mechanical parameter measurement, can solve the problems of easy bending and relaxation of steel wire, difficulty in installation, inconvenience in reading or collecting data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

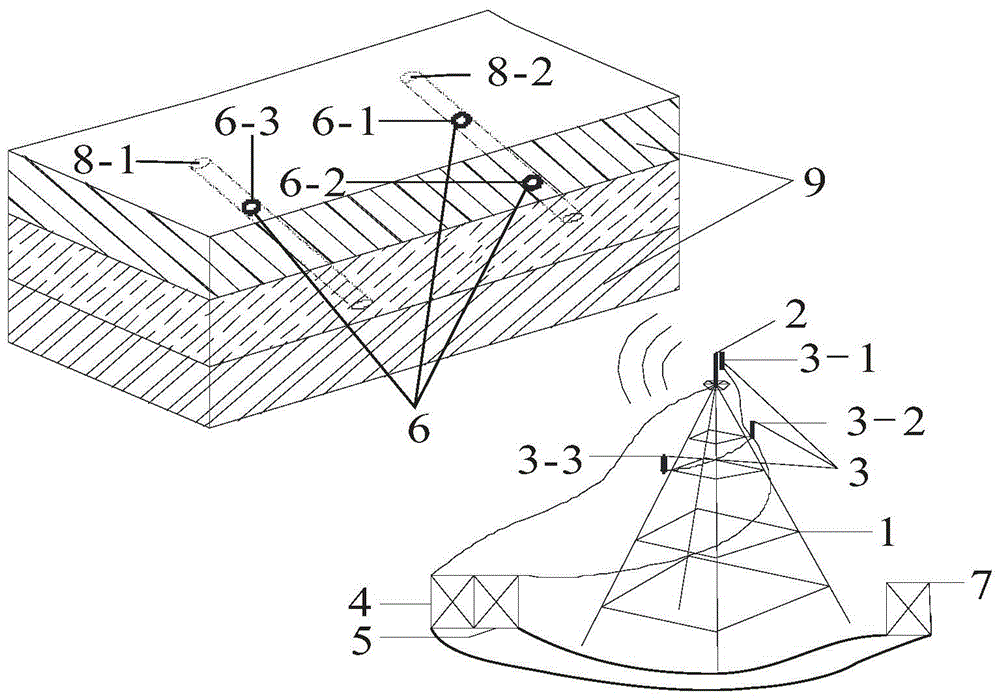

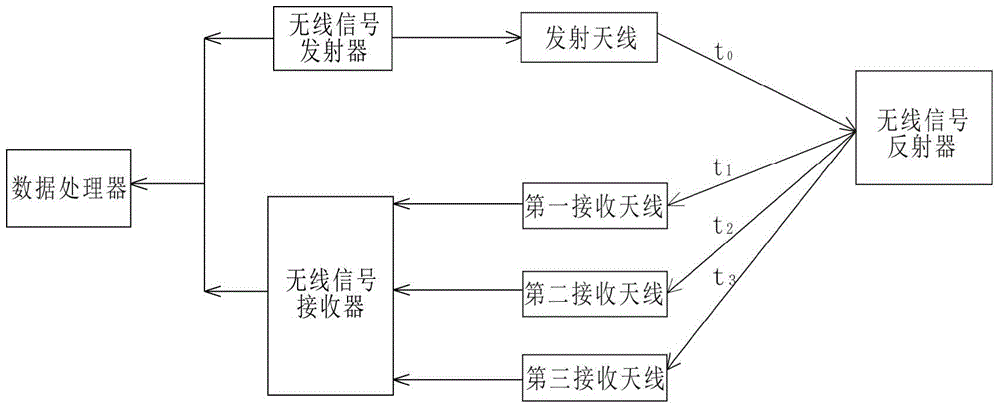

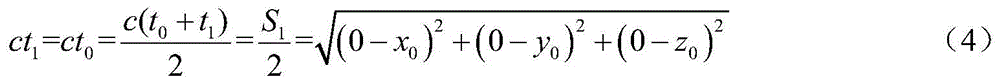

[0041] The method for measuring the three-dimensional coordinates of the base point in the rock mass borehole and the wireless measuring device thereof according to the present invention will be further described below in conjunction with the accompanying drawings. It must be pointed out that the following examples are only used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Those skilled in the art can make some non-essential improvements and adjustments to the present invention according to the above-mentioned content of the invention. The specific implementation still belongs to the protection scope of the present invention.

[0042] In this embodiment, the wireless signal reflector 6 is a hollow sphere made of copper, the outer diameter of the hollow sphere is 25mm, and the thickness of the shell is 5mm; the length of each transmitting antenna and receiving antenna is 20cm, and the chip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com