A loading test bench for clamping components of submarine pipelines

A clamping component and loading test technology, which is applied in the field of test benches, can solve the problem of no loading test equipment for clamping components of submarine pipelines, and achieve the effect of compact structure, large loading range, and design and optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

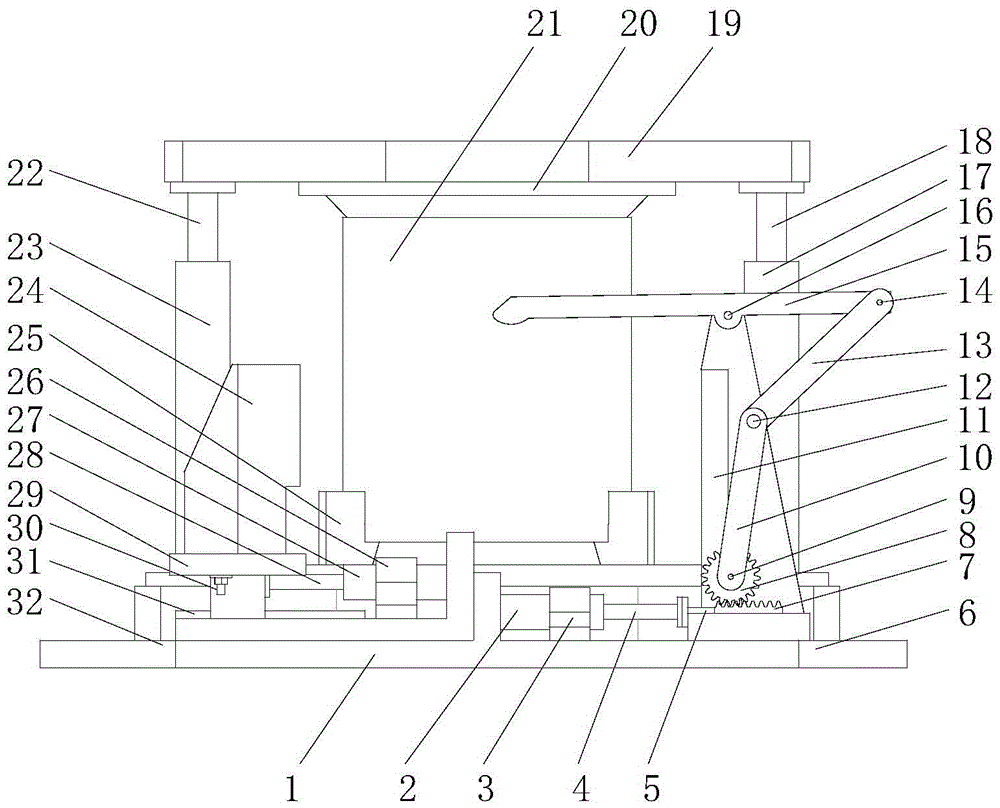

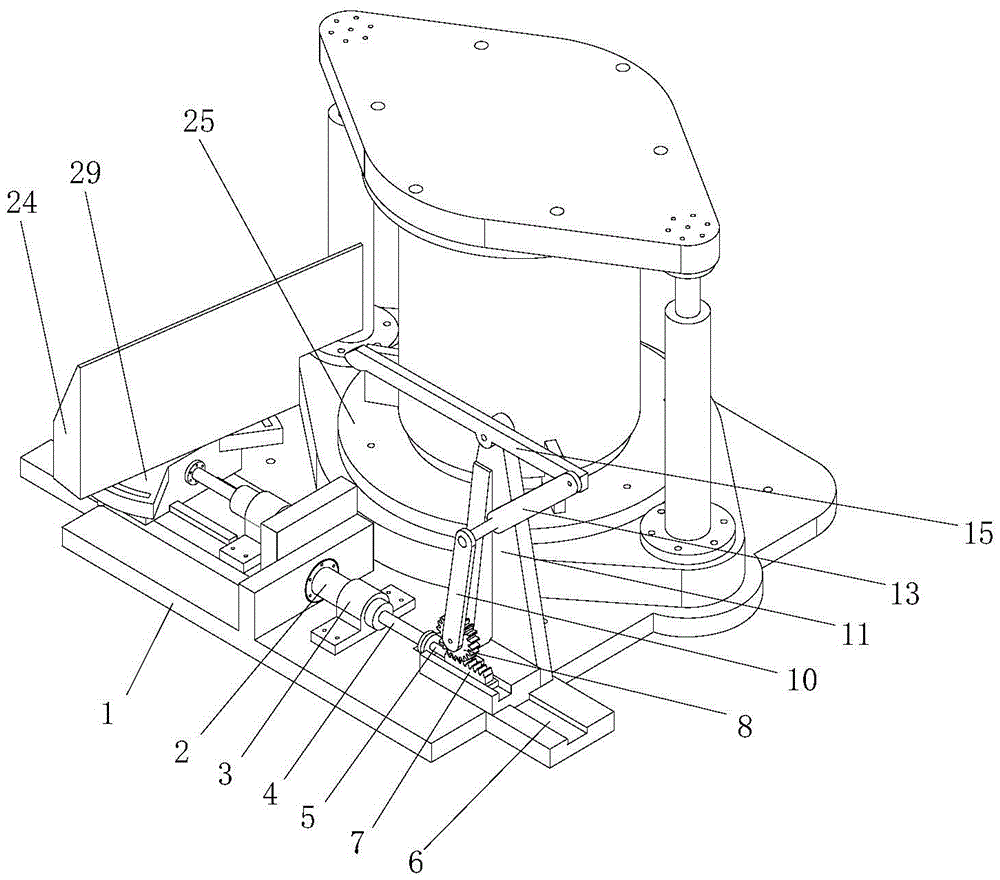

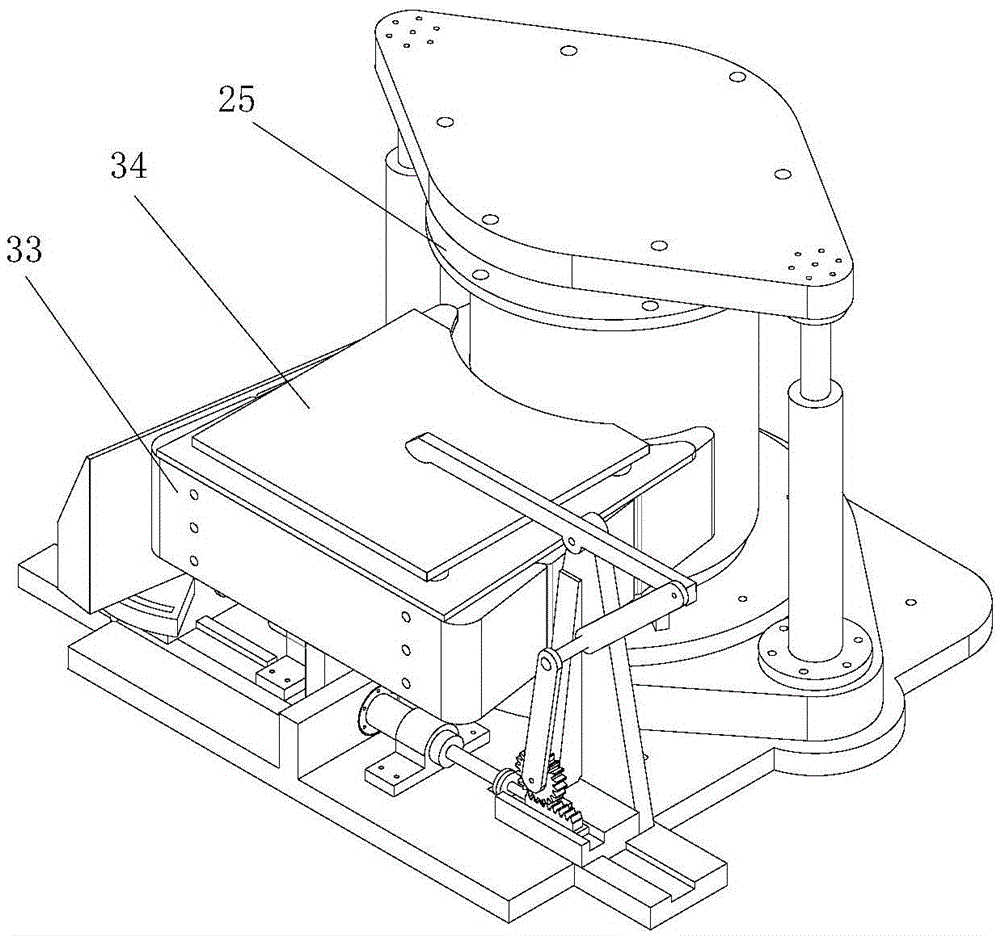

[0015] combine Figure 1~3 , the second hydraulic cylinder barrel 2 is fixed to the base 1 through the hydraulic cylinder fastening support 3, and the hydraulic cylinder barrel 2 is connected to the fixed plate of the base 1 with bolts in the axial direction to limit the axial movement of the hydraulic cylinder and turn. The piston rod 4 of the hydraulic cylinder is connected with the rack rod 5 by bolts to transmit power, and then the power is transmitted to the lower connecting rod 10 through the rack and pinion mechanism composed of the rack 7 and the gear 8, wherein the rack 7 and the support 11 The guide rail forms a moving pair, and a travel switch is arranged on the guide rail to limit the range of movement of the rack 7 on the guide rail. The gear 8 fixes the hinge pin shaft 9 and the bearing 11 through the gear to form a rotating pair. The lower connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com