A kind of cold-rolled steel plate and preparation method thereof

A technology for cold-rolled steel sheets and slabs, applied in the field of cold-rolled steel sheets and their preparation, can solve the problem of high cost of cold-rolled steel sheets with strength and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

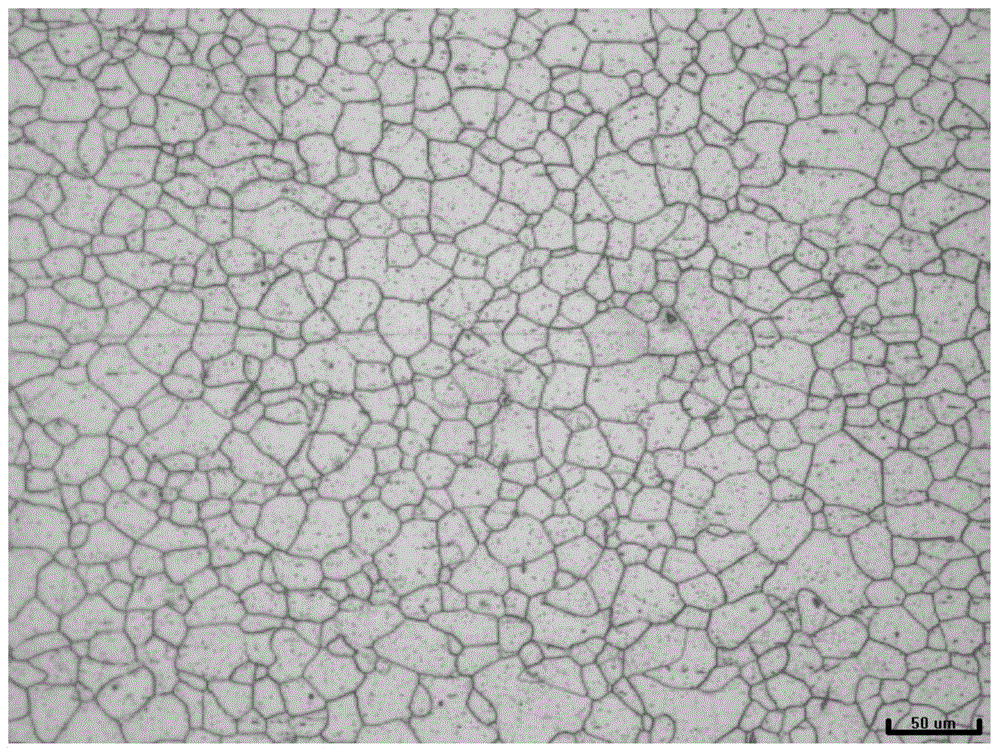

Image

Examples

preparation example Construction

[0024] The preparation method of the cold-rolled steel plate provided by the present invention comprises: hot-rolling, coiling, cold-rolling, annealing, skin-passing and tension-leveling of the slab sequentially, wherein, after hot-rolling and before coiling, the hot-rolled The obtained intermediate slab is cooled to 700-850°C, the cooling rate of the cooling is 76-95°C / s; the coiling temperature is 730-770°C; the reduction rate of the cold rolling is 55-74 %; the annealing method is continuous annealing. In the annealing process, the intermediate slab obtained after cold rolling passes through heating section, soaking section, primary cooling section, overaging section and secondary cooling section successively. The end temperatures of the intermediate slab obtained after the cold rolling in the heating section, the soaking section, the primary cooling section, the overaging section and the secondary cooling section are respectively 740-790°C, 800-870°C, 200-300°C, 250-320°C,...

Embodiment 1-3

[0054] This example is used to illustrate the cold-rolled steel sheet of the present invention and its preparation method.

[0055] The continuous casting slab of the present invention is obtained by smelting in a converter, Ca treatment in an LF furnace, RH decarburization and continuous casting, and its composition is shown in Table 1. The continuous casting slab is heated in the heating furnace to the rough rolling opening temperature and enters the reversible rough rolling unit. After rough rolling, the intermediate slab enters the hot coil box, and the strip head and tail are exchanged, and then the finish rolling is carried out. After finishing rolling, it is rapidly cooled to the final cooling temperature according to the specified cooling rate, and then after a period of online air cooling, coiling is carried out at the coiling temperature (the hot rolling process and the cooling process are carried out according to the conditions in Table 2). Carry out cold rolling an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com