Disengaging system

A separation system and clutch technology, applied in the field of separation systems, can solve problems such as line marks and sealing system failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

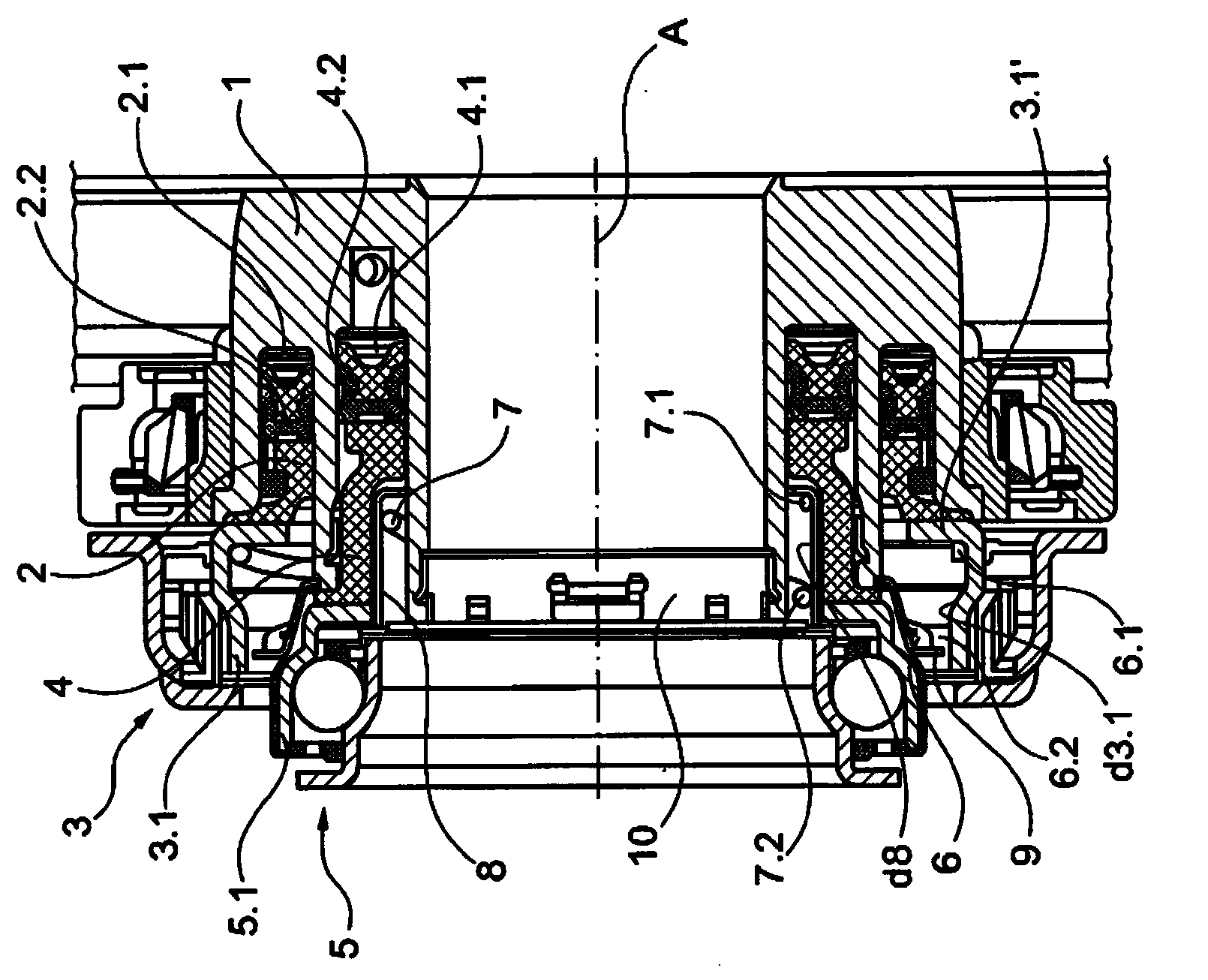

[0036] according to figure 1 , the slave cylinder is designed as a CSC centered slave cylinder and is used to actuate the dual clutch. The slave cylinder has a housing 1 in which a first piston 2 is arranged displaceably in the direction of a longitudinal axis A in a pressure chamber 2 . There is a first seal 2.2 on the first piston 2 in the direction of the first pressure chamber 2.1, and the first piston 2 acts at the end opposite to the first seal 2.2 against a radially outer first The radially inwardly facing region 3 . 1 ′ of the stationary / rotationally fixed first bearing ring 3 . 1 of the bearing 3 engages.

[0037] The second piston 4 is mounted axially displaceable concentrically within the first piston 2 in the second pressure chamber 4.1 and is sealed relative to the second pressure chamber 4.1 via a second seal 4.2. At the end opposite to the second seal 4.2, the second piston 4 acts on the radially inwardly facing region 5.1 of the stationary / rotationally fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com