Oil recovery process

A technology for recovering oil and formations, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve the problems of being incompatible with oil and unsuitable for strengthening oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

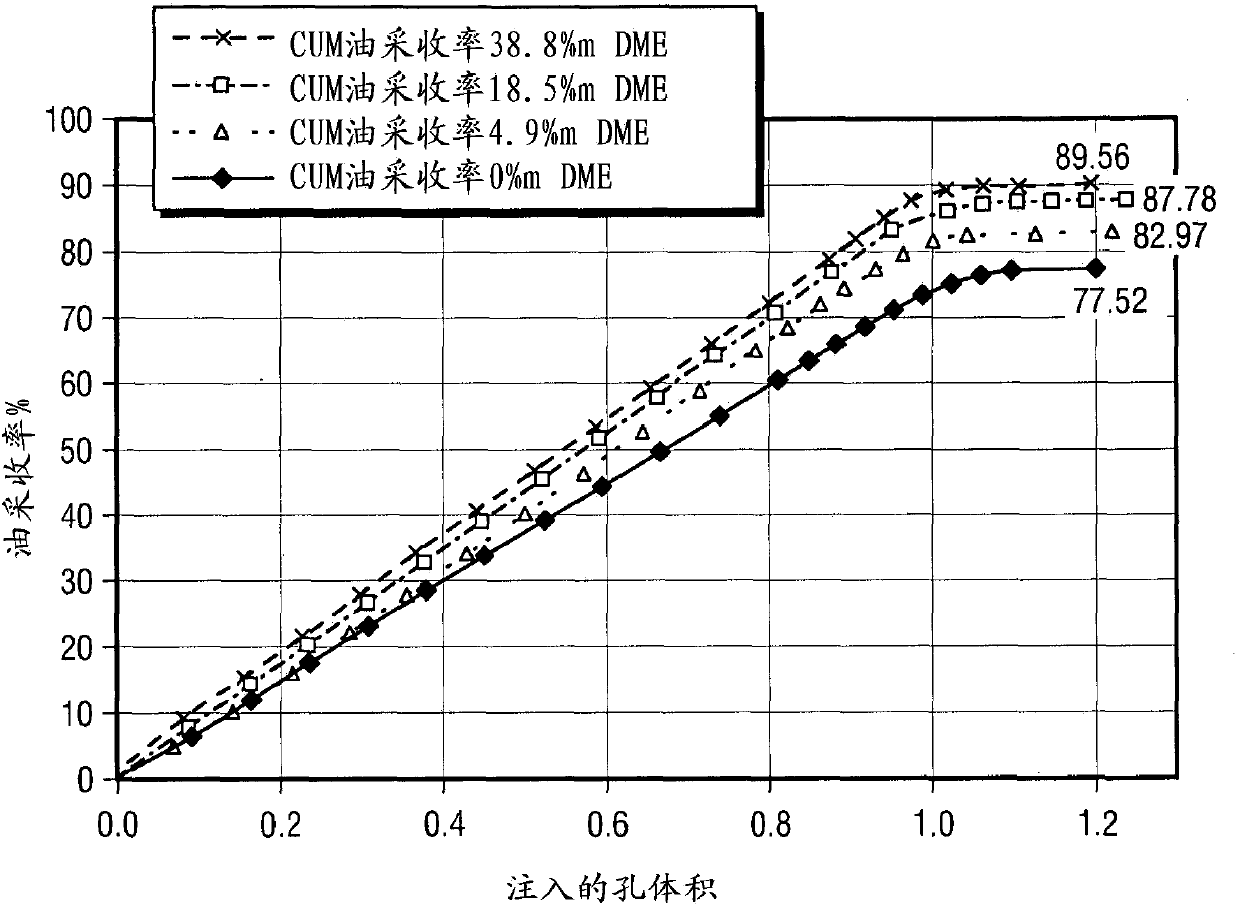

[0055] Slim tube tests were performed to determine the effect of dimethyl ether (DME) on the miscibility of associated gas with oil recovered from the formation. Still crude oil recovered from the formation is filtered and mixed with associated gas produced from the same formation to obtain the desired gas / oil ratio (91.84cc / cc) and bubble point pressure (38.3MPa) to produce a performance of recombined new oil). The composition of this freshly recovered oil is provided in Table 1 and the composition of the associated gas in Table 2.

[0056] Table 1

[0057]

[0058]

[0059] Physical properties calculated based on GPA2145-00 physical constants

[0060] Table 2

[0061]

[0062]

[0063]

[0064] Standard conditions: 60F, 283.7K, 14.696psia (0.101325MPa)

[0065] Reconstituted fresh oil was used to saturate a 1 / 4" (0.635 cm) ID and 40' (12.19 m) length straw packed with 200 mesh sand. The slim tubing had a pore volume of 141.7 cc and the slim tubing had a 40...

Embodiment 2

[0075] An oil swell test was performed to measure the effect of adding 20.74 mole % DME to the oil used in Example 1 above. The oil has the properties listed in Table 1 above. For comparison, an oil swelling test was performed on a blank sample containing only oil, and the addition of 20 mol% CO to the oil 2 oil swelling test.

[0076] Oil swelling tests were performed in visible PVT cells. For each test, the pond was charged with a measured volume of freshly produced oil (as described in Example 1) at a pressure above saturation pressure (38.3 MPa) and at the formation temperature of the formation producing the oil (79.4°C). prepared above), and 20.7 mol% of DME, 20 mol% of CO 2 . The cell is pressurized as the gas is added until the fluid is a single phase. When the cell is pressurized, a constant composition expansion test is performed to measure the saturation pressure and the relative liquid volume below the saturation pressure of the resulting fluid. While pressuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com