Multifunctional green tea production line

A multifunctional, production line technology, applied in the direction of tea treatment before extraction, can solve the problems of wasting production resources, increasing tea production costs, and production efficiency needs to be further improved, and achieve the effect of reducing use costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

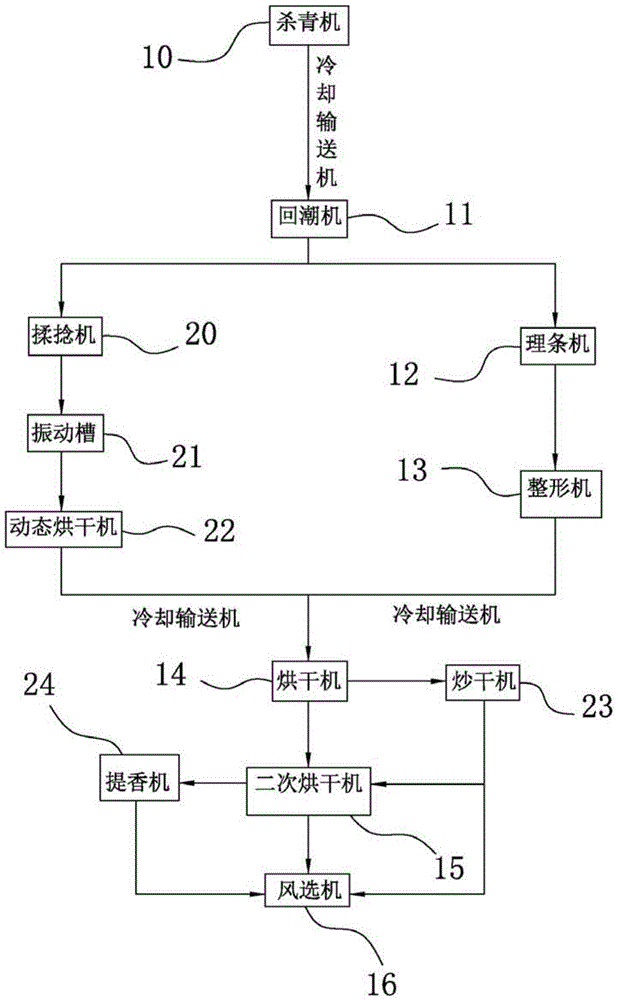

[0016] Such as figure 1 As shown, a multi-functional green tea production line includes those connected in sequence by a conveying mechanism:

[0017] Crushing machine 10, used to finish tea;

[0018] Moisture regaining machine 11, the main structure is a long-stroke conveyor belt, used for natural cooling of tea leaves;

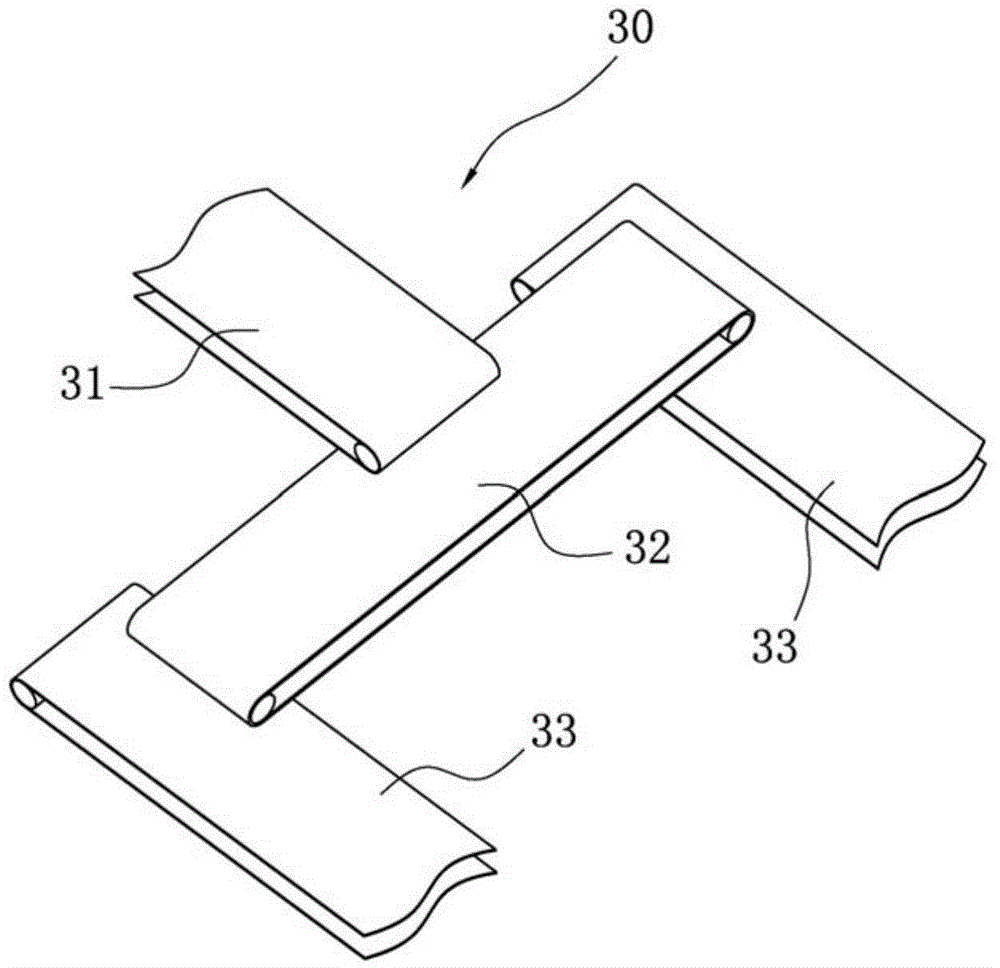

[0019] The striping machine 12 includes a plurality of strip-shaped grooves arranged side by side, and the strip-shaped grooves reciprocate along the width direction of the groove, and a heating device is provided under the strip-shaped grooves for arranging and shaping the tea leaves;

[0020] The shaping machine 13, which is similar in structure to the striping machine, further organizes and shapes the tea;

[0021] The dryer 14 mainly includes a long-stroke conveyor belt set in a high-temperature environment for preliminary drying of tea leaves;

[0022] The secondary dryer 15, which has the same structure as the dryer, is used for the secondary drying of tea;

[002...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap