Novel connecting structure for cross beam and upright post of glass curtain wall

A glass curtain wall and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as deformation of aluminum alloy columns, increase construction difficulty, and affect aesthetic effects, etc., to achieve enhanced firmness, fast installation speed, and reduced The effect of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

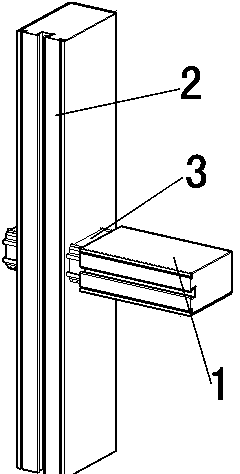

[0025] Example: as Figure 4 Shown: a new connection structure between beams and columns of glass curtain wall, which includes beam 1, column 2, beam core sleeve 3, opposite bolts 4, galvanized iron sheet 5, and drilling screws 6. The beam 1 is an aluminum alloy beam with a model of 120. Column 2 is a 160 aluminum alloy column. The beam core sleeve model is 120.

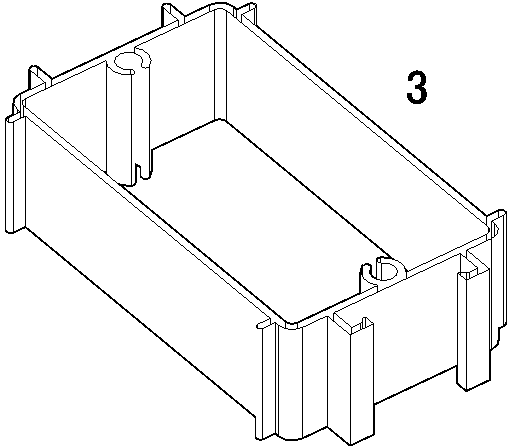

[0026] like figure 1 As shown, the inner side of the beam core sleeve 3 is provided with sleeve holes. The beam core sleeve 3 is 30mm long.

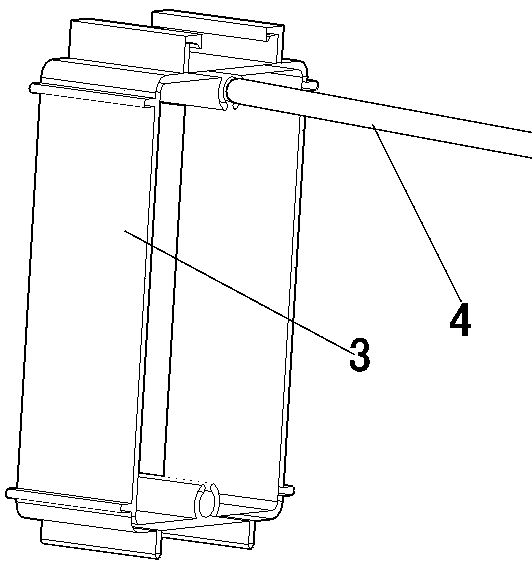

[0027] like figure 2 As shown, one end of the opposite bolt 4 is inserted into the sleeve hole.

[0028] like image 3 As shown in the figure, the beam core sleeve 3 is cut into corresponding lengths, the perforations are punched on the vertical and spaced columns 2 that are installed and adjusted, and the beam core sleeve 3 is fixed on the column 2 using the opposite bolts 4; the interior of the beam 1 is a hollow structure , Beam 1 is cut according to the size of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap